Cleaning and drying device for corrosion foil

A technology of drying device and cleaning device, applied in the directions of drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of human injury, inconvenient operation of corrosion foil cleaning device, and poor processing quality of aluminum foil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

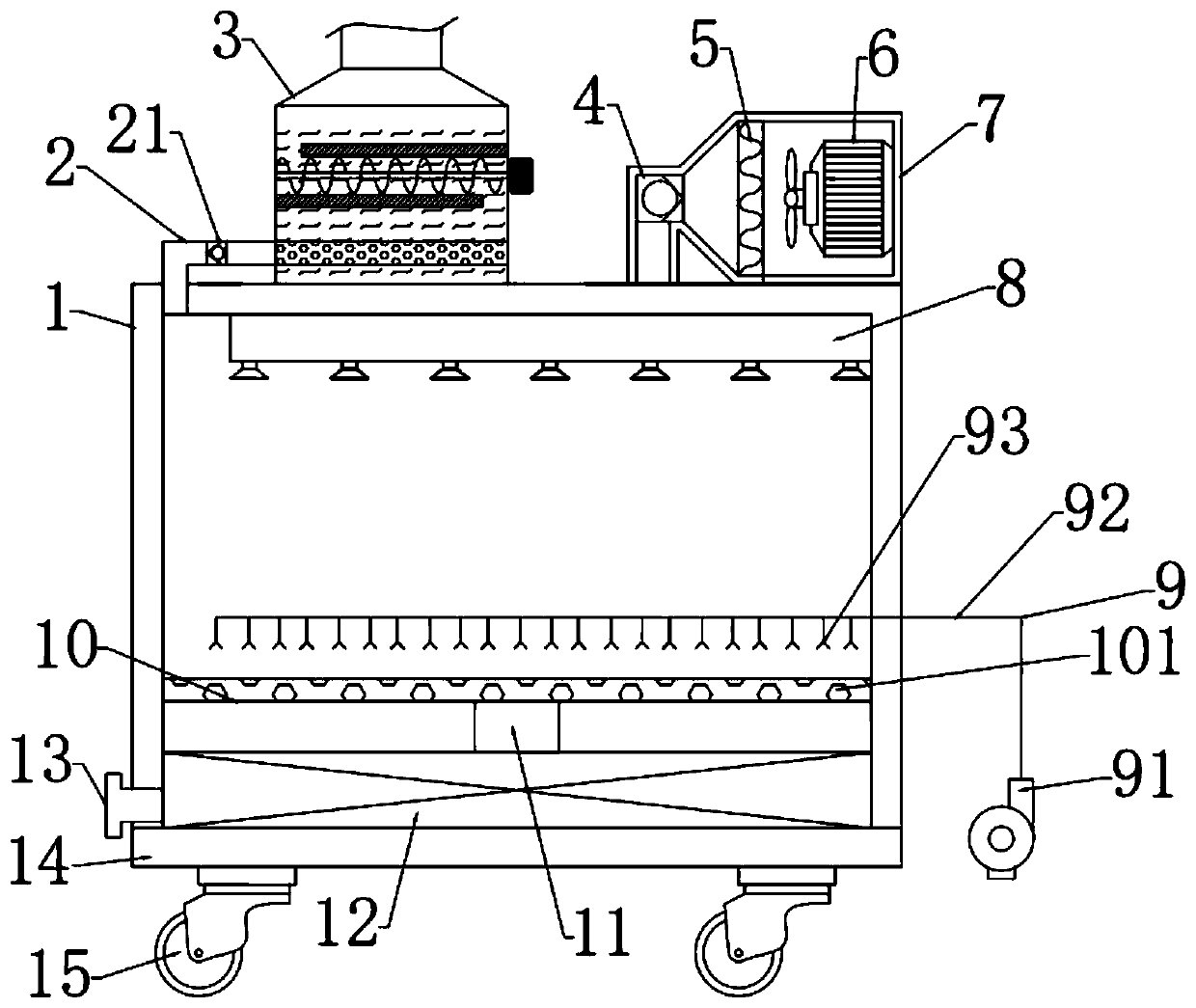

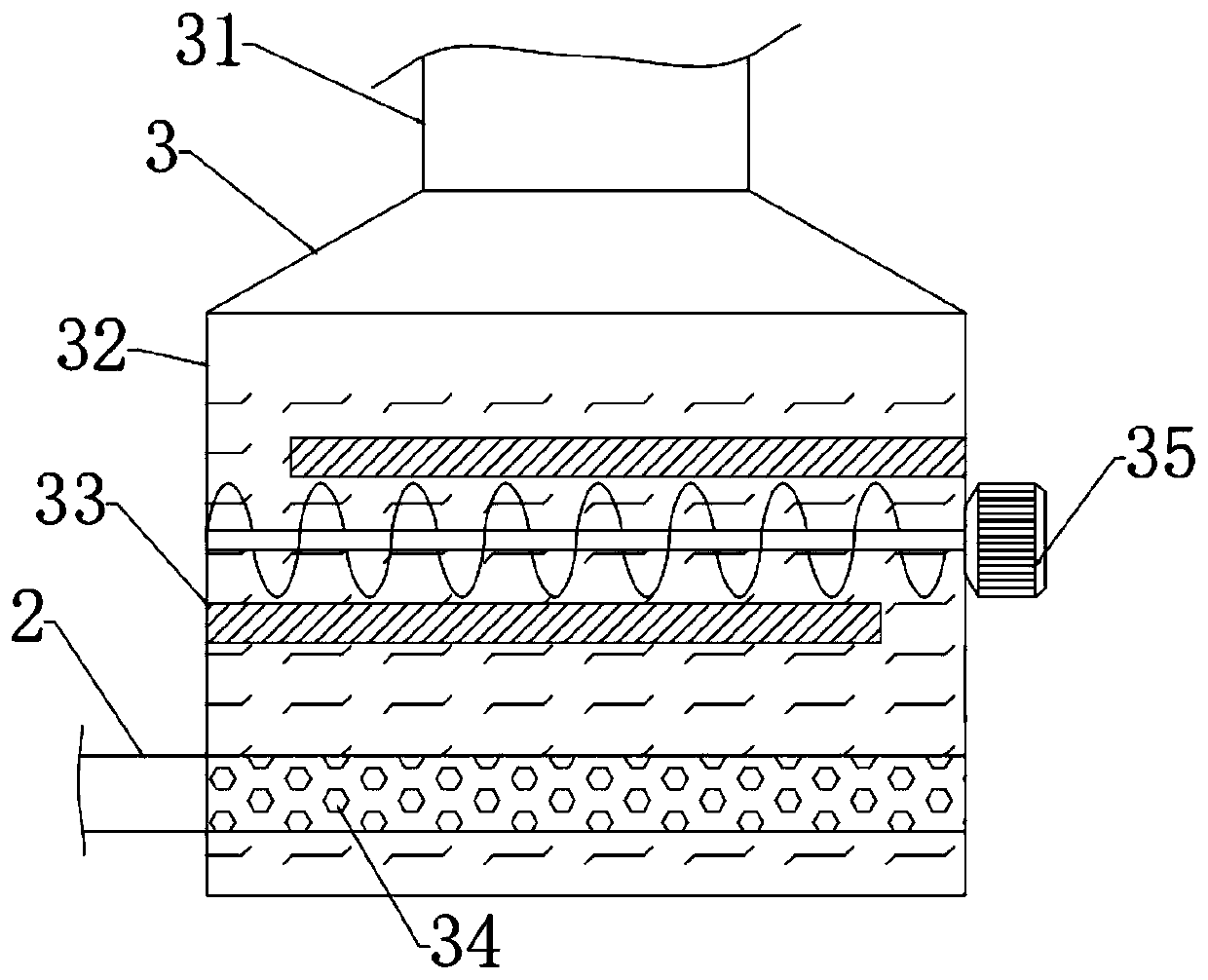

[0020] see Figure 1~2 , in an embodiment of the present invention, a corroded foil cleaning and drying device includes a box body 1, an acid gas treatment device 3 and a hot air device 7 are fixedly connected to the top of the box body 1, and the acid gas treatment device 3 passes through the air outlet pipe 2 It communicates with the inner cavity of the box body 1, and the top of the inner cavity of the box body 1 is provided with a hot air pipe 8 horizontally. The upper end of the pipe 8 communicates with the hot air device 7 through a pipe, and the inner cavity of the box body 1 is located below the hot air pipe 8 and is provided with a cleaning device 9 , a cleaning plate 10 is provided below the cleaning device 9 , and a There is a rotating shaft 11, the cleaning plate 10 is rotatably connected with the rotating shaft 11, a heater 12 is provided at the bottom of the box body 1, the corrosion foil is placed on the cleaning plate 10, the nozzle 93 sprays cleaning liquid fo...

Embodiment 2

[0029] A corroded foil processing system includes the corroded foil cleaning and drying device as described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com