Electronic detonator chip leg wire riveting device and processing flow based on same

An electronic detonator and riveting device technology, applied in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of high labor intensity, operators are vulnerable to mechanical damage, low production efficiency, etc., to reduce labor intensity and improve equipment production. Efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

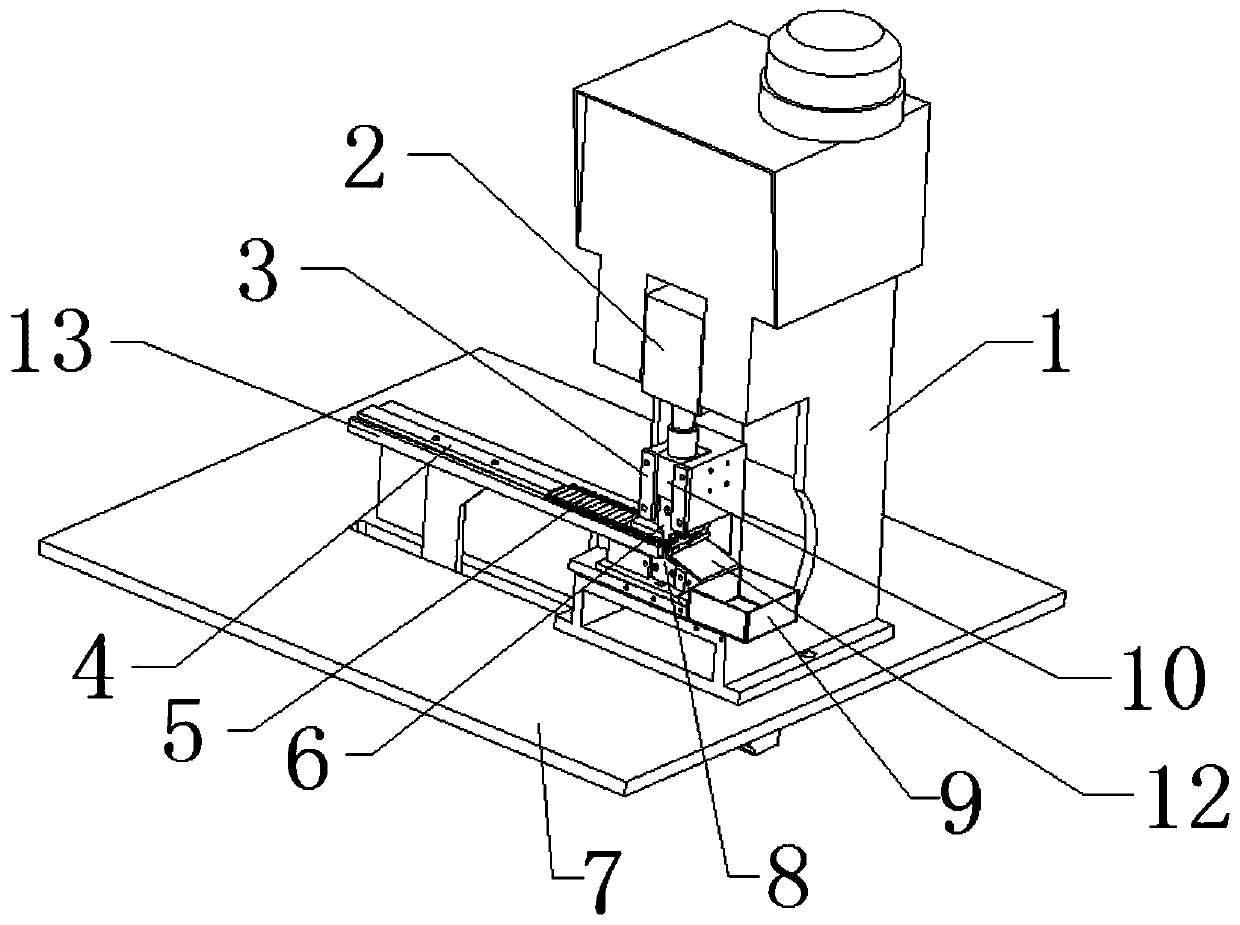

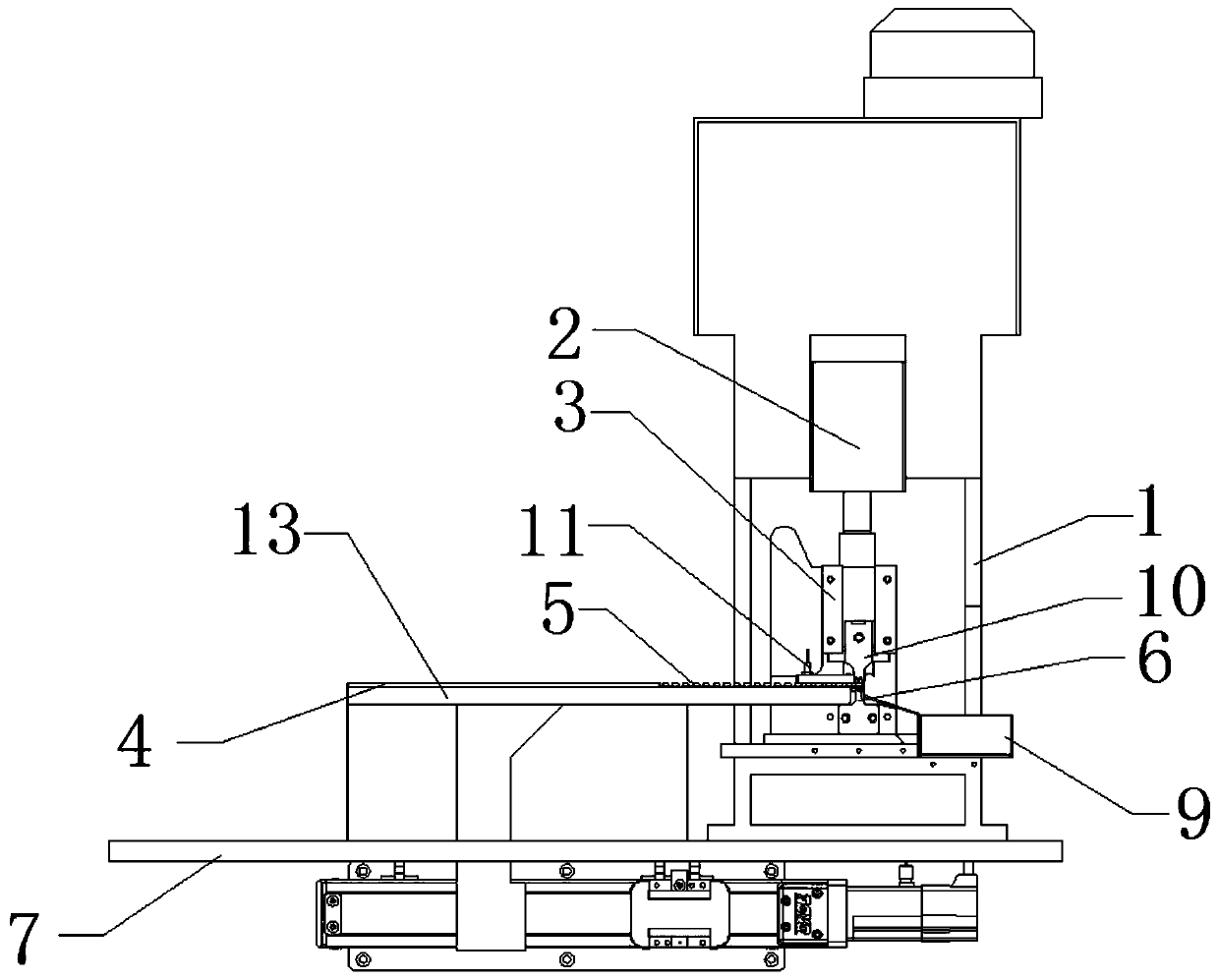

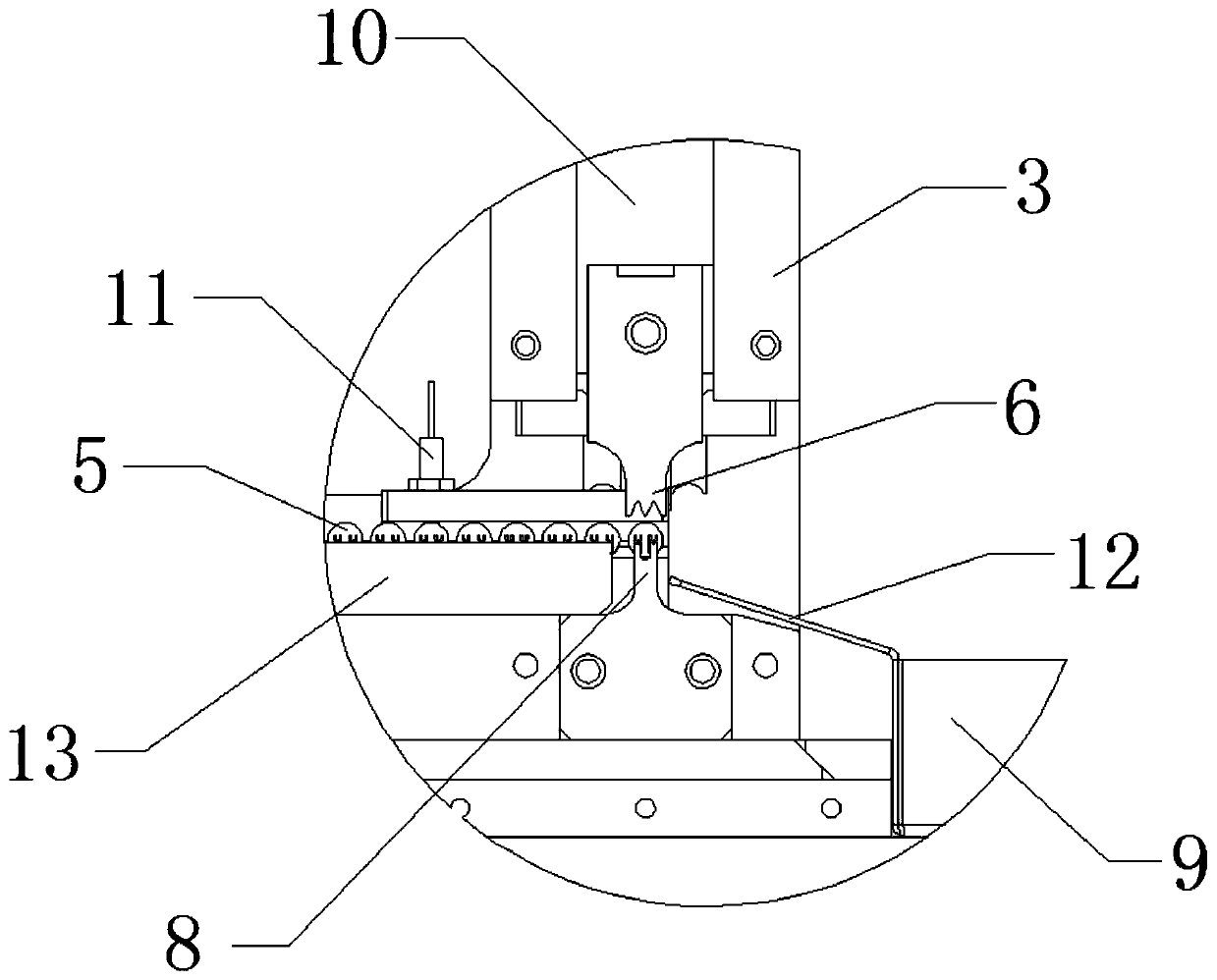

[0027] see Figure 1-5 , the present invention provides a technical solution: a leg riveting device for an electronic detonator chip, including a terminal machine 1, an output shaft 2 of the terminal machine, a slide rail 3, a stepping feeding mechanism 4, an upper riveting knife 6, a chassis 7, Lower riveting knife 8, slide block 10 and guide rail 13, described terminal machine 1 and guide rail 13 are all arranged on the chassis 7, described guide rail 13 is provided with step feeding mechanism 4, and the output shaft 2 of described terminal machine is arranged on The inner top of the terminal machine 1. The slide rail 3 is fixed inside the terminal machine 1 and is located on the lower side of the output shaft 2 of the terminal machine. The slider 10 is slidably connected to the inside of the slide rail 3. The output shaft 2 of the terminal machine is fixedly connected, the upper riveting knife 6 is fixedly arranged on the side of the slider 10 away from the output shaft 2 o...

Embodiment 2

[0031] As a preferred solution of Embodiment 1, a detection mechanism 11 is also included, and the detection mechanism 11 includes an electronic detonator chip detector, a recovery box 9 and a slant plate 12, and the electronic detonator chip detector is arranged on the slide rail on the terminal machine 1 3 On the side close to the guide rail 13, the recovery box 9 is set on the terminal machine 1, and is located on the side of the lower riveting knife 8 away from the guide rail 13, between the end of the guide rail 13 close to the upper riveting knife 6 and the recovery box 9 A slant plate 12 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com