Method for detecting centering degree of vertical roll by adopting laser infrared gradienter

A technology of infrared level and level, which is applied in the direction of using optical devices, active optical measuring devices, instruments, etc., can solve the problems of inability to meet the needs of on-site precision detection, the failure of the vertical roll surface to make a base point, and the low detection accuracy of the vertical roll. The effect of safe and convenient operation, long service life and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

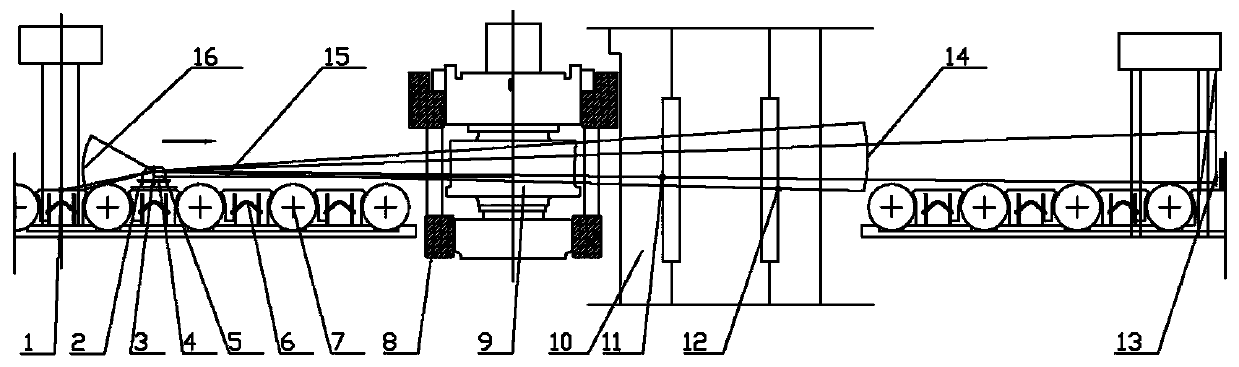

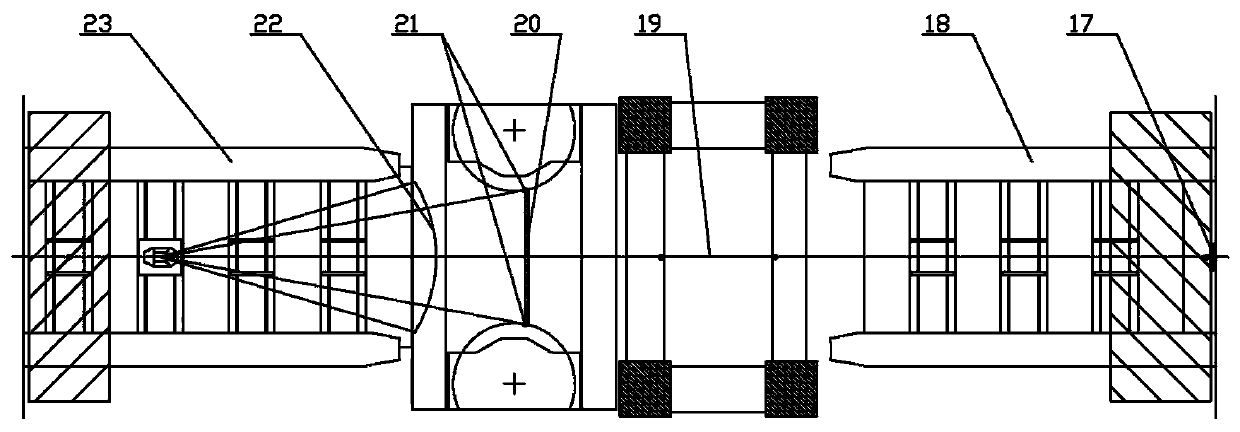

[0024] A method for detecting the centering degree of vertical rollers by using a laser infrared level meter is carried out according to the following steps:

[0025] 1) Use the 5-line laser infrared level function, 4 vertical and 1 level: one horizontal line and four vertical lines. It can measure the level and plumb line, has the functions of coarse leveling and self-leveling of the circular vial, and is equipped with a base and a foot screw;

[0026] 2) Testing conditions: set the vertical rolls on both sides to the middle width specification of the strip, and each factory can also set it to the normal rolling width, and set the front and rear side guide plates to the maximum position;

[0027] 3) The laser level is placed in front of the vertical roller machine, and a steel plate is laid on the roller flower frame close to the width measuring instrument, the laser infrared level is placed stably, the foot screw of the level is adjusted, and the circular level is used for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com