An intelligent monitoring method for kitchen appliance hazards combined with edge computing

An edge computing and intelligent monitoring technology, applied in neural learning methods, measuring devices, instruments, etc., can solve the problems of insufficient reliability, low accuracy and intelligence, and difficulty in ensuring the safety of kitchen appliances. High accuracy and the effect of reducing system delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in more detail below with reference to the examples and the drawings, but the embodiments of the present invention are not limited thereto.

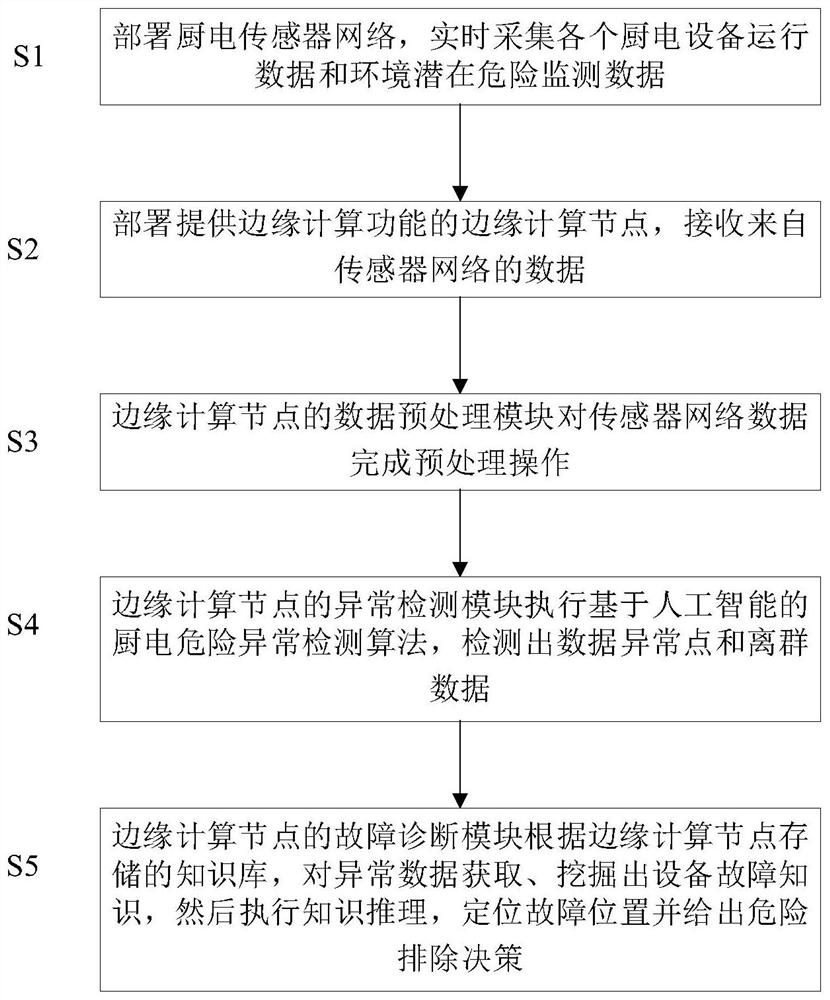

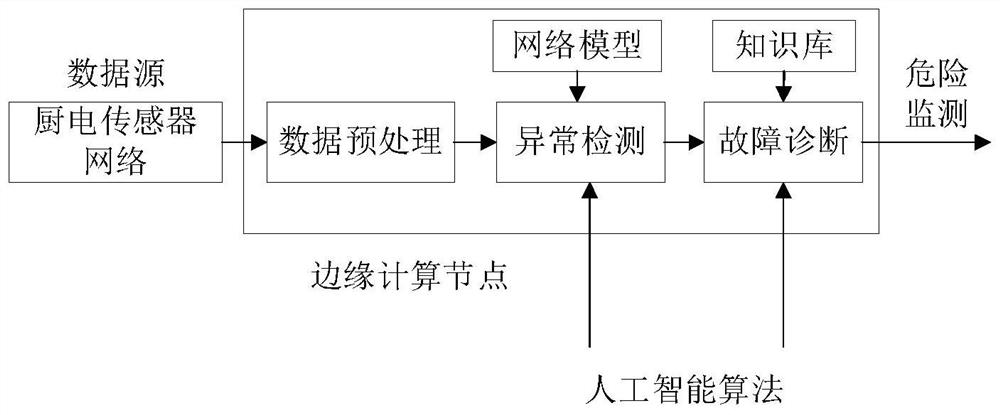

[0031] The present invention is directed to real security risks kitchen electric potential of the device, is disclosed a method of monitoring hazardous intelligent electric kitchen one binding edge computing, using advanced computing technology and artificial intelligence technology edge. The method by implementing electric kitchen real-time data acquisition, data anomaly detection and kitchen electrical fault diagnosis, to locate the fault location and the corresponding decision to exclude the risk of electric kitchen, kitchen help to reduce the risk of dangerous accidents, and thus protect the lives of residents property.

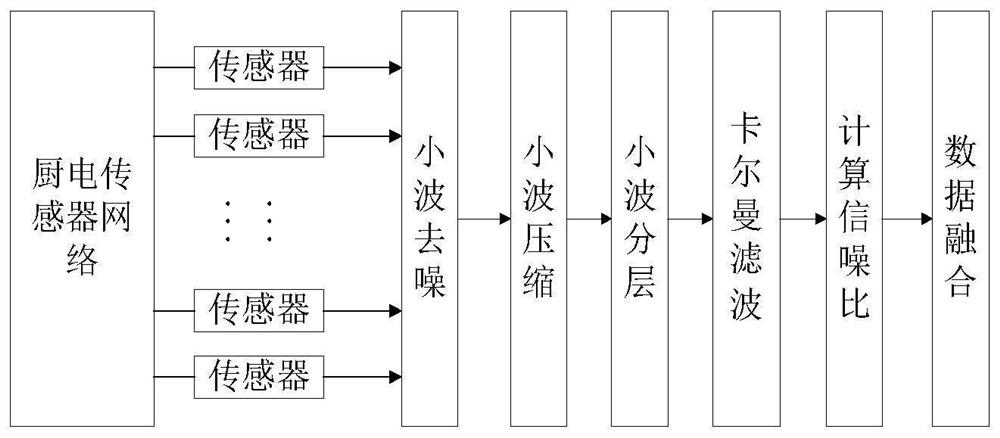

[0032] Corresponding location in the home kitchen electrical equipment and kitchen are arranged various types of sensors, comprising a toxic gas sensor, a temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com