Exposure machine and contraposition method thereof

An exposure machine and position alignment technology, applied in the field of exposure machines, can solve the problems of long alignment time, affecting production efficiency, etc., and achieve the effects of short alignment time, increasing output and satisfying quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

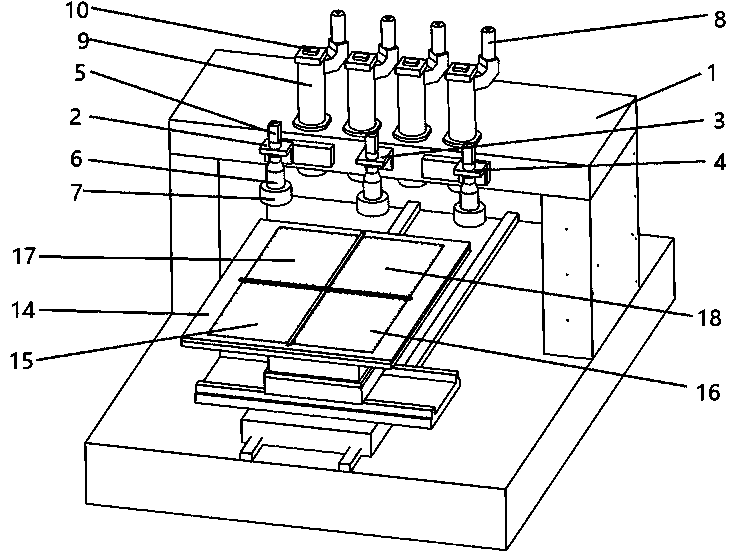

[0045] Embodiment 1: as figure 1 As shown, multiple exposure substrates are placed on the substrate table 14 at the same time to realize fast loading and unloading. Since the exposure substrates are positioned along the multi-center scale on the substrate table 14, the positioning accuracy is guaranteed. The alignment system includes a left alignment camera 2, an alignment mechanism 3 and a right alignment camera 4, the left alignment camera 2 and the right alignment camera 4 slide along the guide rail in the X direction, the alignment mechanism 3 is fixed on the gantry, The exposure system is also installed on Gantry 1. After the board placement is completed, the left alignment camera 2 obtains the coordinates of the left alignment points of the two exposed substrates 15 and 17 on the left, and the right alignment camera 4 obtains the coordinates of the right alignment points of the two exposed substrates 16 and 18 on the right , the alignment mechanism 3 acquires the coordi...

Embodiment 2

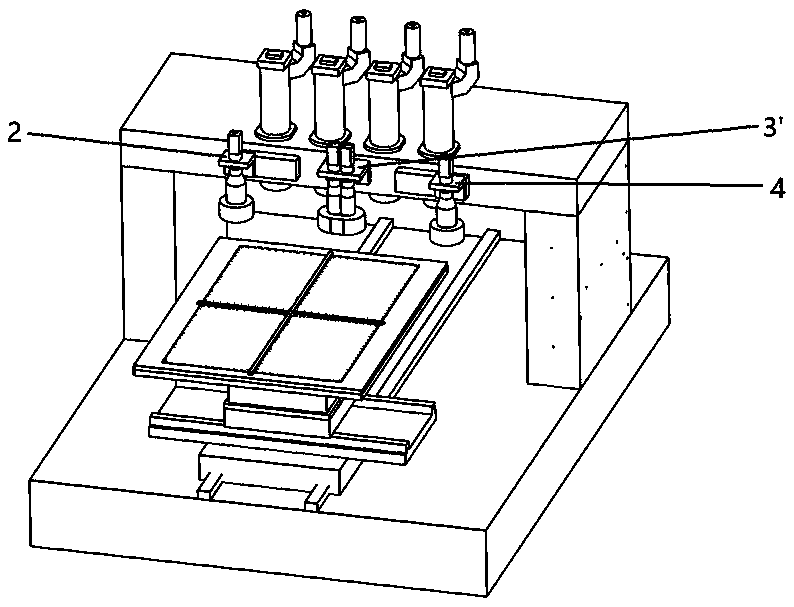

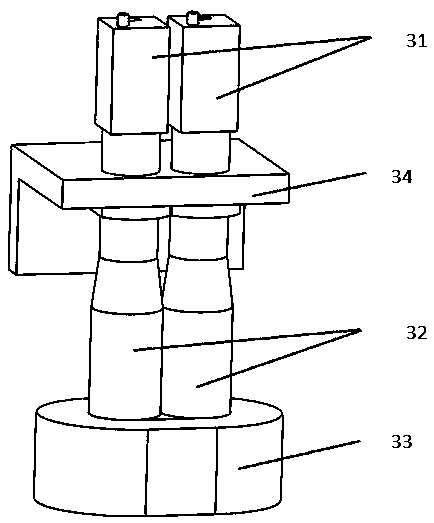

[0046] Embodiment 2: as figure 2 As shown, multiple exposure substrates are placed on the substrate table 14 at the same time to realize fast loading and unloading. Since the exposure substrates are positioned along the multi-center scale on the substrate table 14, the positioning accuracy is guaranteed. The alignment mechanism 3' adopts such as image 3 As shown in the structure of dual cameras and dual lenses, after the board placement is completed, the left alignment camera 2 obtains the coordinates of the left alignment points of the left two exposed substrates 15 and 17, and the right alignment camera 4 obtains the coordinates of the right two exposure substrates. The coordinates of the alignment points on the right side of the exposure substrates 16 and 18, the alignment system 3' can simultaneously obtain the coordinates of the alignment points on the right side of the two exposure substrates 15 and 17 on the left and the left sides of the two exposure substrates 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com