Separation structure between voltage regulation tapping leads of transformer

A technology for tapping leads and transformers, applied in the directions of transformer/inductor cooling, transformer/inductor housing, etc., can solve the problems of increasing the cross-section of a single lead, increasing the insulation thickness, and increasing the cost of the lead, so as to reduce the design difficulty. , The effect of reducing insulation thickness and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

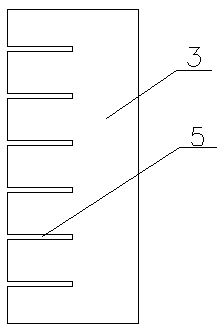

[0024] As shown in the figure, the technical solution of this embodiment is to install insulating pads between the wires in the wire bundle, including the way of installing insulating pads between the wires clamped by the wire clamps and when there are no wires. The method of installing insulating pads between the wires at the clamping place. A wire that is not held by a wire clamp, generally refers to a wire in a wire bundle that is located between two wire clamps.

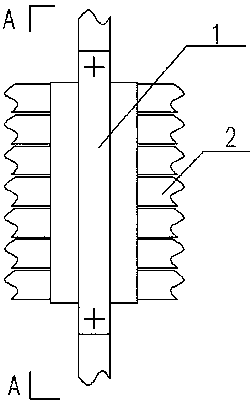

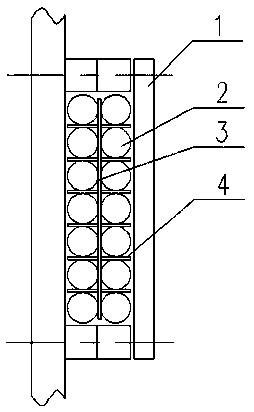

[0025] For the solution at the clamping place of wire clip 1, such as Figure 1-4 shown. It includes a wire clamp 1 and a wire bundle clamped in the wire clamp 1 . The wires 2 in the wire bundle in this embodiment are clamped by the wire clamp 1 into two longitudinal rows, and a longitudinal insulating spacer, that is, a first longitudinal spacer 3, is installed between the two rows of wires, and each row of adjacent wires 2 A horizontal insulating spacer, that is, a first transverse spacer 4, is arranged betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com