A lamination equipment for lithium ion battery processing

A lithium-ion battery and stacking technology, which is applied in secondary batteries, battery assembly machines, secondary battery manufacturing, etc., can solve the problems of pole piece damage, lower stacking efficiency, and large horizontal space, and achieve high processing efficiency , Lamination effect is good, and the effect of convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

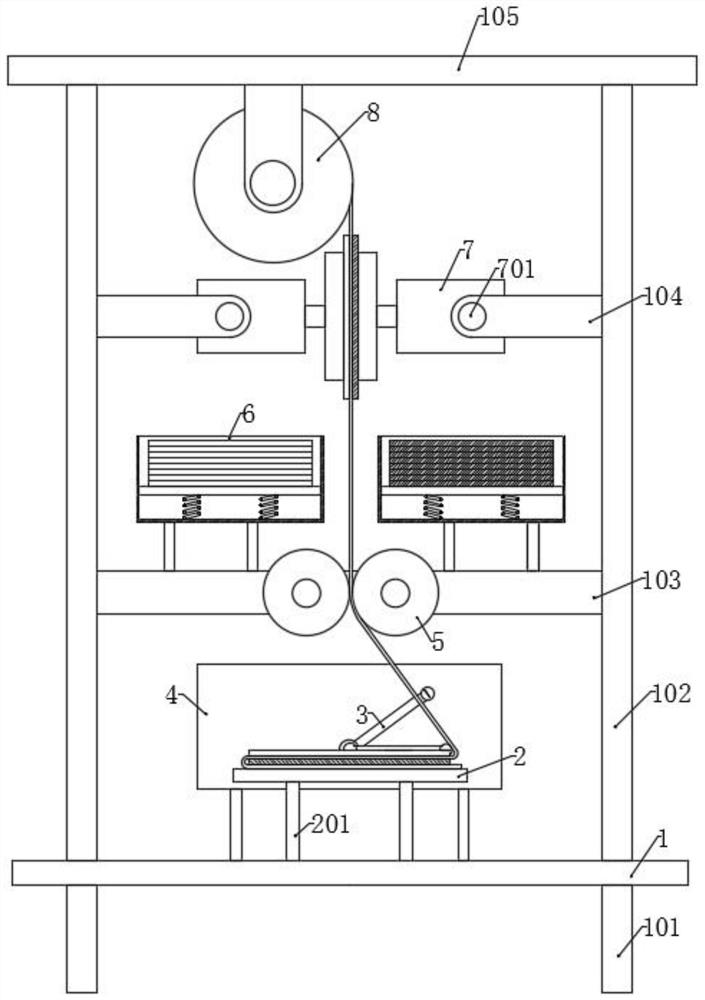

[0035] Please refer to the accompanying drawings, the present invention provides a technical solution: a lamination equipment for lithium ion battery processing, including a base plate 1, lower support rods 101 are fixed at the four corners of the bottom surface of the bottom plate 1, and upper support rods 101 are fixed at the four corners of the top surface. Support rod 102, the first support 103 is fixed between the bottom of the upper support rod 102, the second support 104 is fixed symmetrically on the upper part, and a top plate 105 is fixed together on the top, and a workbench 2 is arranged above the bottom plate 1, and the working The bottom surface of the platform 2 is correspondingly connected with the base plate 1 through the connecting rod 201. The two sides of the workbench 2 are symmetrically provided with the laminated assembly 3, and the outer side of the laminated assembly 3 is symmetrically provided with the driving box 4, and the driving box 4 is provided with...

Embodiment 2

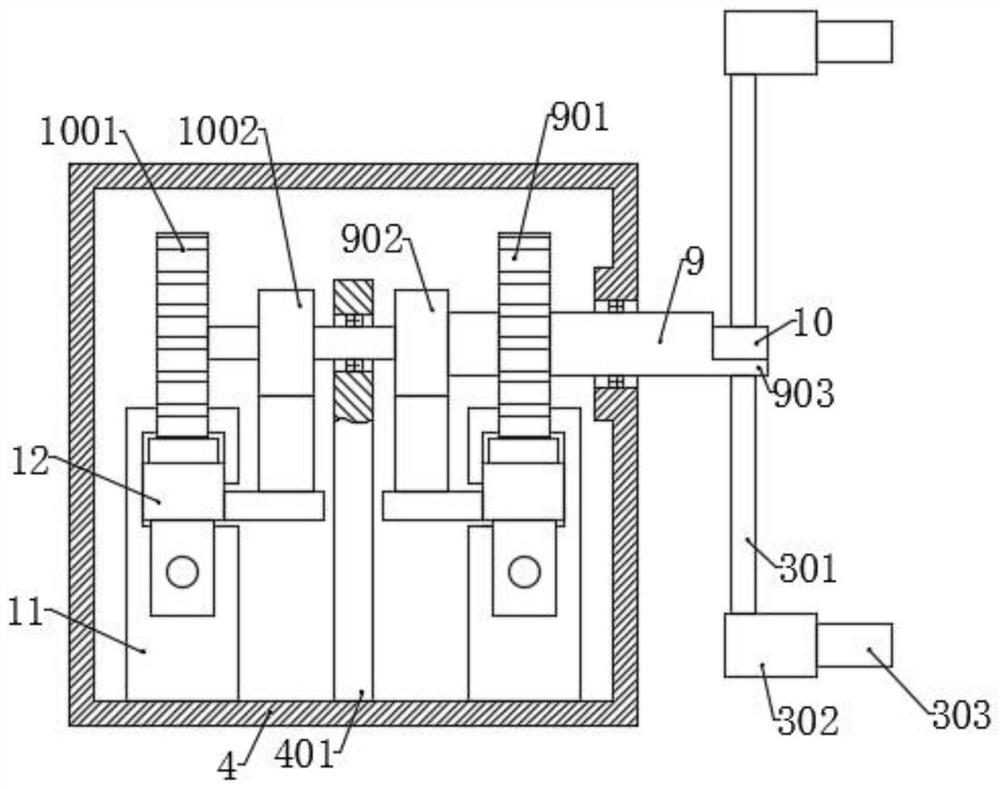

[0044] On the basis of Embodiment 1, an arc-shaped plate 903 is also fixed on the outer end of the rotating cylinder 9. The central angle corresponding to the arc-shaped plate 903 is 30°, and the inner and outer surfaces of the rotating cylinder 9 are in line with the inside and outside of the rotating cylinder 9. The sides are coincident, and the outer end coincides with the outer end of the rotating shaft 10. The fixing rods 301 of the two laminations 3 are respectively fixed on the outer side of the arc-shaped plate 903 and the rotating shaft 10, and the two fixing rods 301 are connected to the rotating shaft 10. The distances between the outer ends of the rotating shafts 10 are equal.

[0045] By setting the fixed rod 301 on the circular arc plate of the rotating cylinder 9, while not affecting the rotation of the rotating shaft 10, the lamination assemblies 3 on both sides are in the same plane, so that the structure of two lamination assemblies 3, The size and the like a...

Embodiment 3

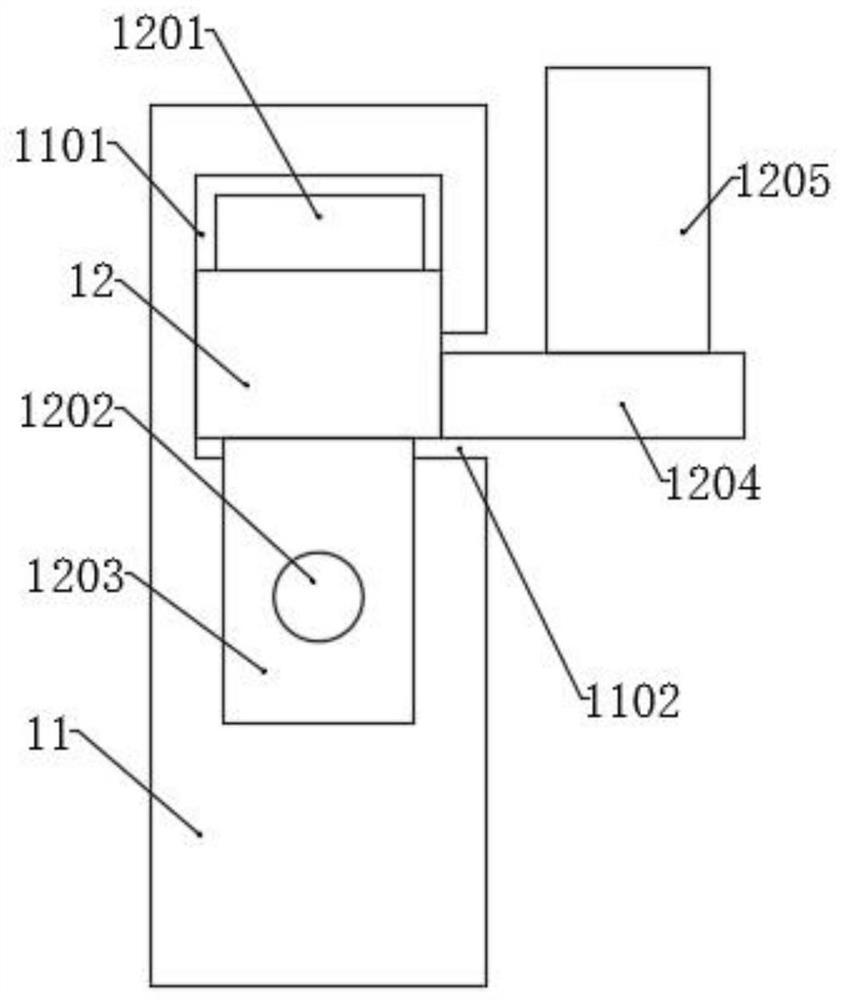

[0047] On the basis of Embodiment 1, the bottom end of the connecting rod 201 passes through the bottom plate 1 and protrudes, and the extending end is fixed to the limit plate 202, and the connecting rod 201 is also sleeved with a first spring 203, and works The bottom surface of the platform 2 is correspondingly connected with the top surface of the bottom plate 1 through the first spring 203 .

[0048] When the battery stacks are accumulated to a certain thickness, there will be a gap between the height of the top surface and the original position. Therefore, the thickness of the battery will affect the work of the stack assembly 3. When the first spring 203 is used to rotate the pressing plate 303, the stack assembly 3 will pass The pressing effect of the pressing piece 303 and the first spring 203 enable the workbench 2 to move downward, eliminating the influence of the thickness of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com