Single-phase power factor correction circuit based on three-tube five-level topology

A single-phase power and correction circuit technology, applied in high-efficiency power electronic conversion, output power conversion devices, conversion of AC power input to DC power output, etc., can solve the problems of complex control, insufficient number of levels, and many tubes. , to achieve the effect of simple topology, small voltage stress, and reduced failure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

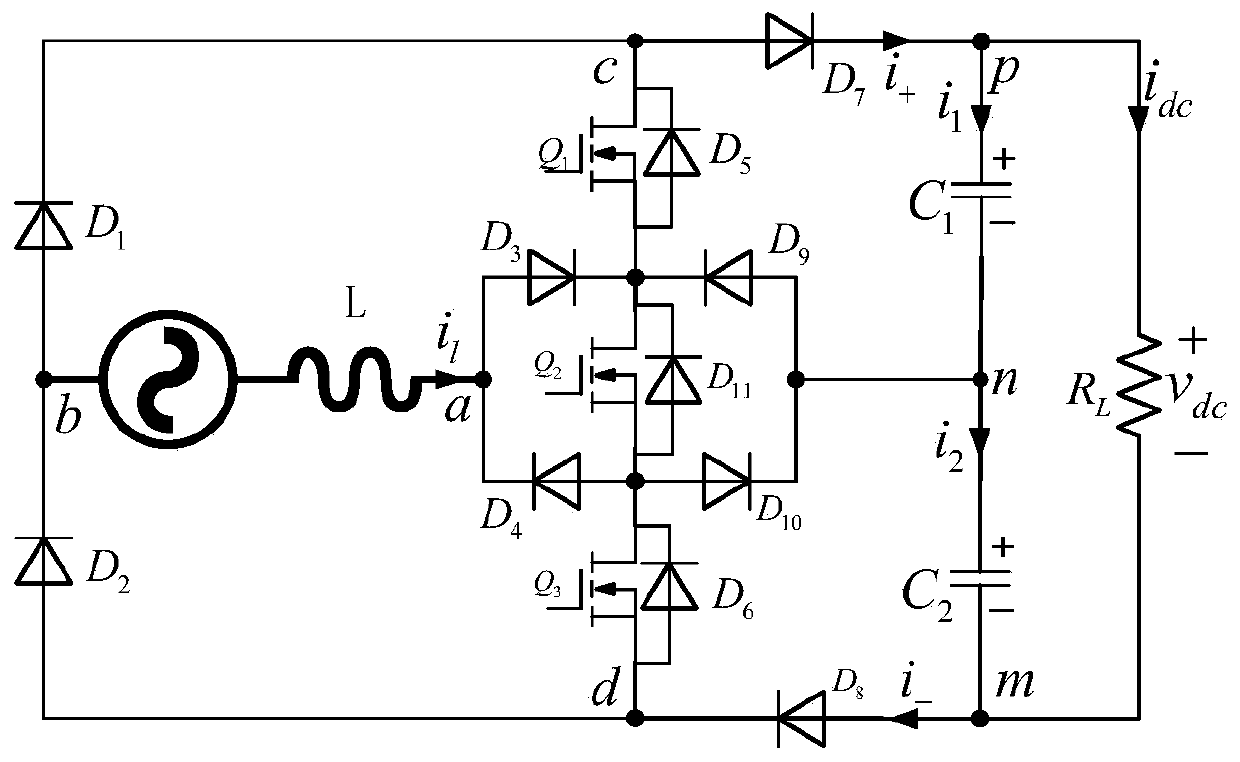

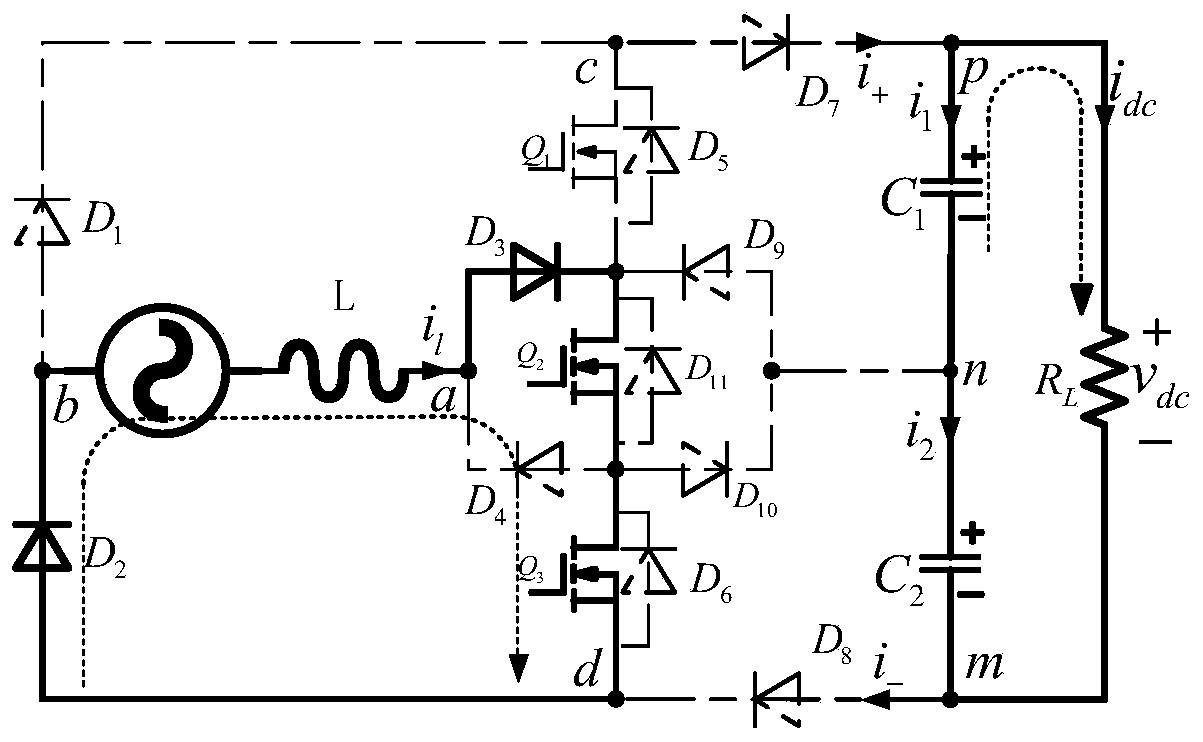

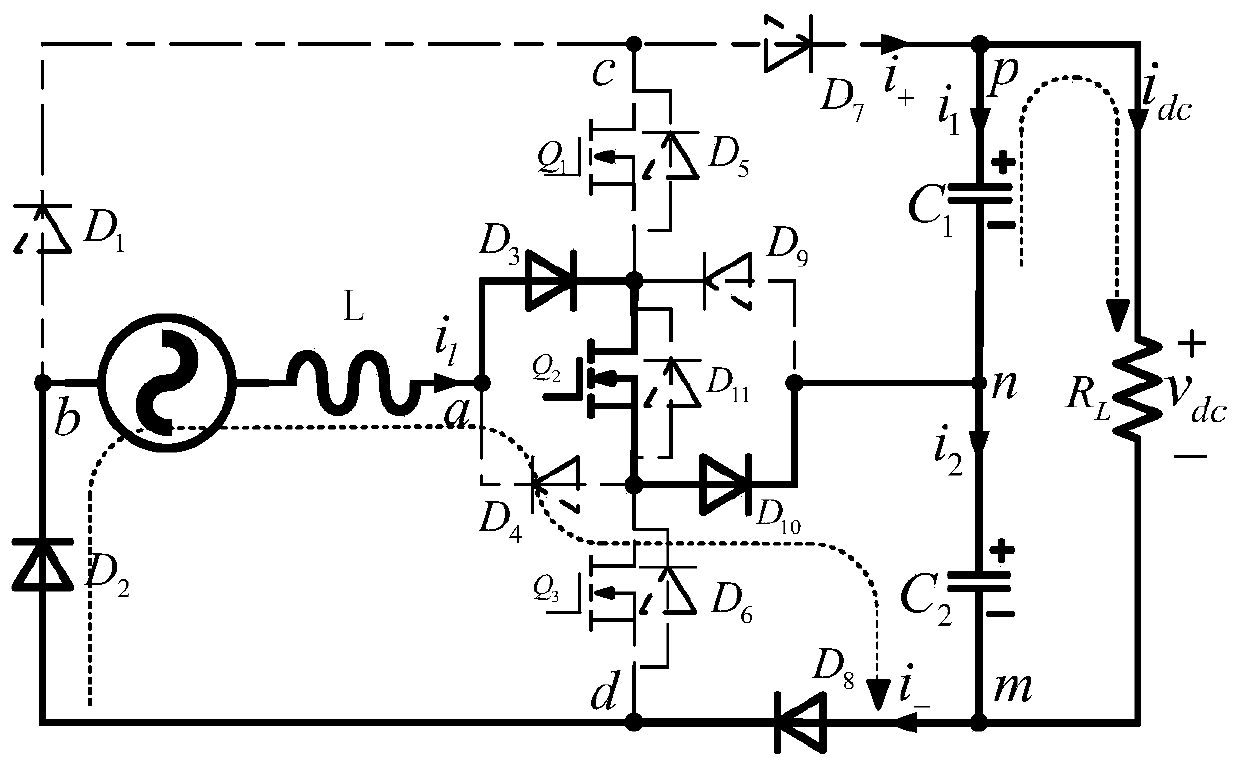

[0042] Such as figure 1 As shown, a single-phase power factor correction circuit based on a three-tube five-level topology includes an inductor L and a switch tube Q 1 , Q 2 , Q 3 , Diode D 1 ~D 11 , Capacitance C 1 , Capacitance C 2 ;

[0043] Connect the diode D to the AC side of the AC power supply 1 Anode, diode D 2 The cathode, the connecting node constitutes the terminal b;

[0044] The other side of the AC power supply AC is connected to one end of the inductor L, and the other end of the inductor L is respectively connected to the diode D 3 Anode, diode D 4 Cathode; the other end of inductor L and diode D 3 , D 4 The connecting node of constitutes the end point a;

[0045] Switch tube Q 2 Connect the drain to diode D 3 Cathode, diode D 9 Cathode, switch tube Q 1 Source

[0046] Switch tube Q 2 The source is connected to diode D 4 Anode, diode D 10 Anode, switch tube Q 3 Drain

[0047] Diode D 7 Cathode connection capacitance C 1 At one end, its connecting nodes constitute an end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com