Control method for improving low-speed performance of electric forklift based on improved M/T method

A technology of electric forklift and control method, which is applied in the direction of low-speed motor control, electric vehicle, motor parameter estimation/correction, etc., can solve the problems of speed closed-loop influence, influence of speed measurement accuracy, poor customer experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

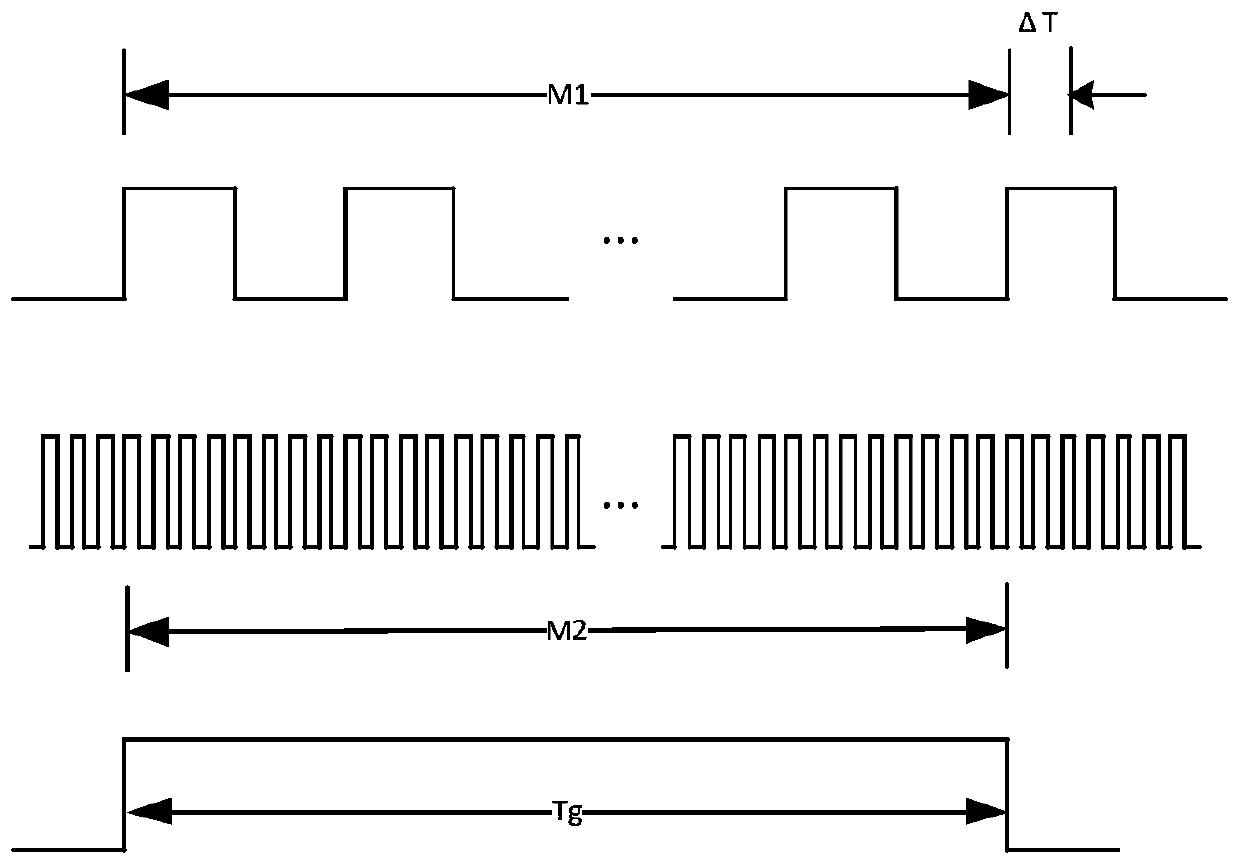

[0019] The said M / T method of the present invention is a kind of velocity measuring method. It adds a capture port on the basis of the M method, and switches to use the T method to measure the motor speed when appropriate.

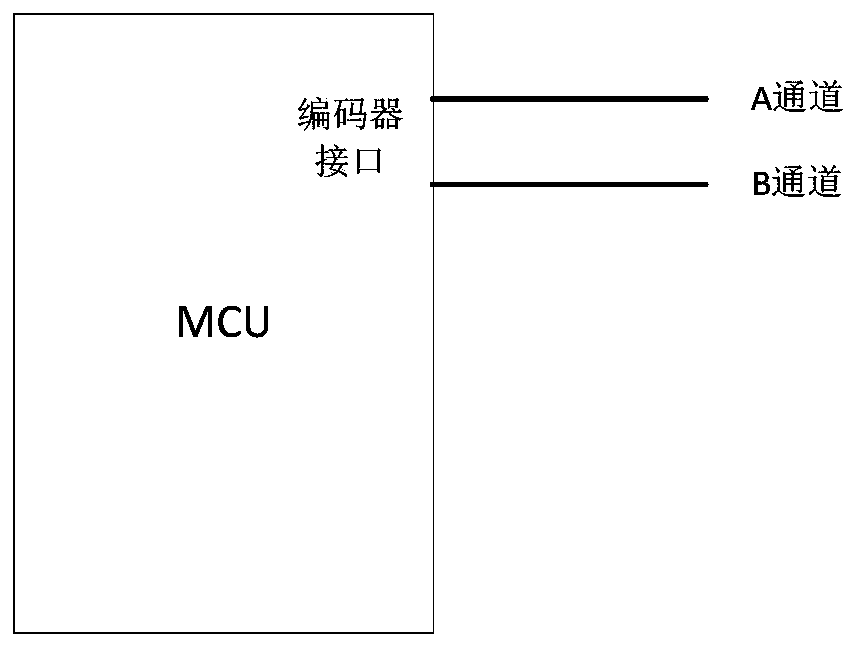

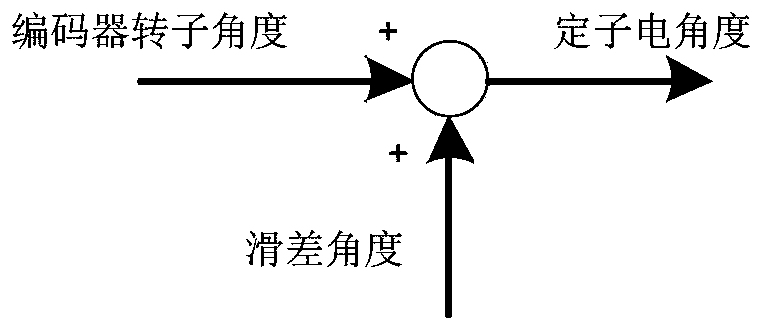

[0020] see figure 2 , Electric forklift manufacturers supporting incremental encoder with A phase and B phase, the incremental encoder is generally installed on the rotor, the motor rotor rotates a circle will generate a square wave on the A channel and B channel. When the number of motor stages is 1 and the number of encoder lines is 80, 80 square wave pulses will be generated on phase A and phase B respectively in one revolution. Then each pulse corresponds to 360 / 80 degrees. Then the electrical angle of the rotor is also 360 / 80 degrees. The stator electrical angle is the rotor electrical angle plus the slip angle. refer to image 3 Schematic diagram of stator electrical angle calculation. The current existing method is to use the encoder interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com