A four-axis integrated servo drive and servo drive control method

A technology of servo drive and control circuit, applied in multiple motor speed adjustments, emergency protection circuit devices, electrical components, etc., can solve the problems of not realizing multi-axis integrated control, etc., achieve flexible synchronization, high real-time performance, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The servo controller proposed by the present invention and its control method are described in more detail below in conjunction with the accompanying drawings:

[0050] The four-axis integrated servo driver includes a control circuit and a power circuit;

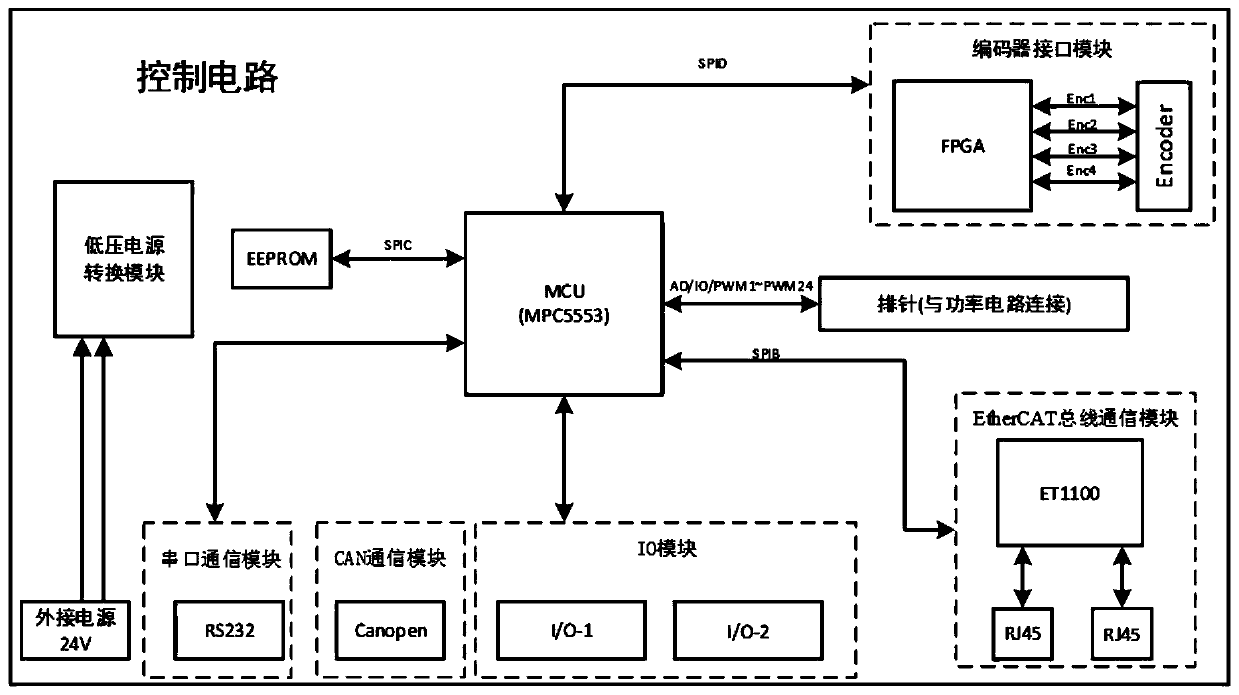

[0051] Such as figure 1 As shown, the control circuit includes a first substrate, an MCU chip disposed on the first substrate, an encoder interface module, a communication module, a low-voltage power conversion module, a first pin row, and an EEPROM chip;

[0052] The encoder interface module, communication module, low-voltage power conversion module and the first row of pins are all electrically connected to the MCU chip;

[0053] The communication module is an EtherCAT bus communication module or a CAN communication module;

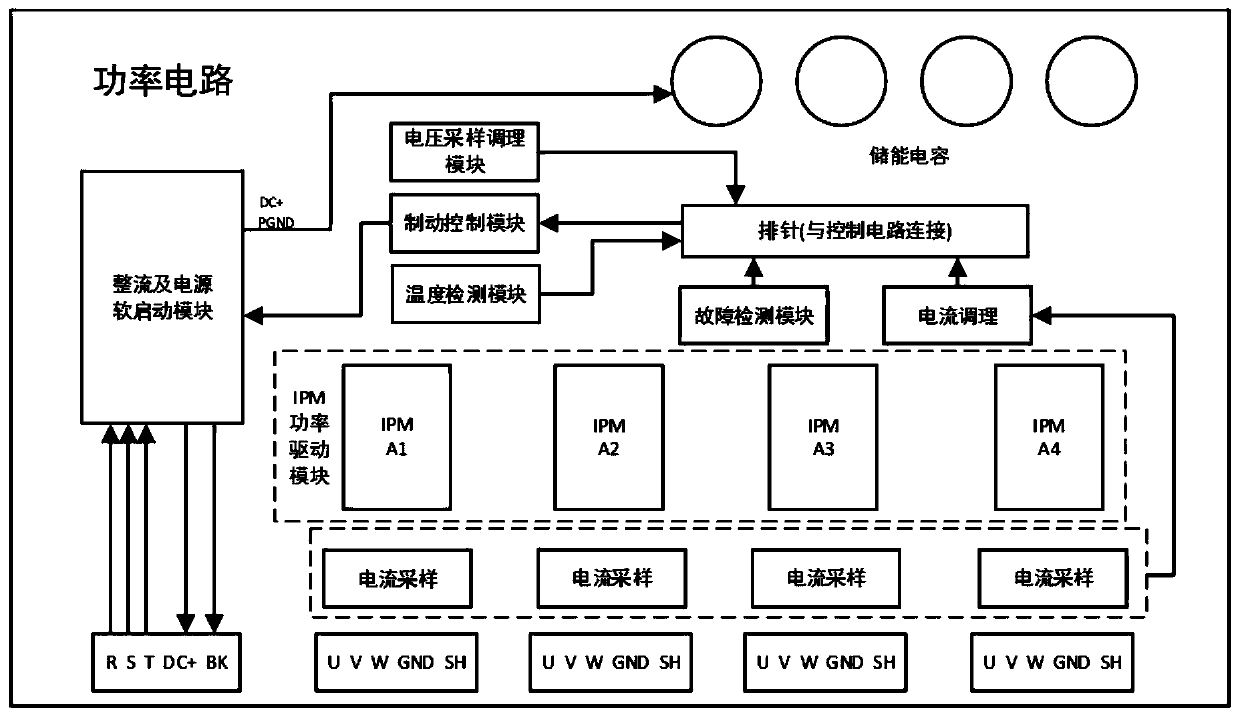

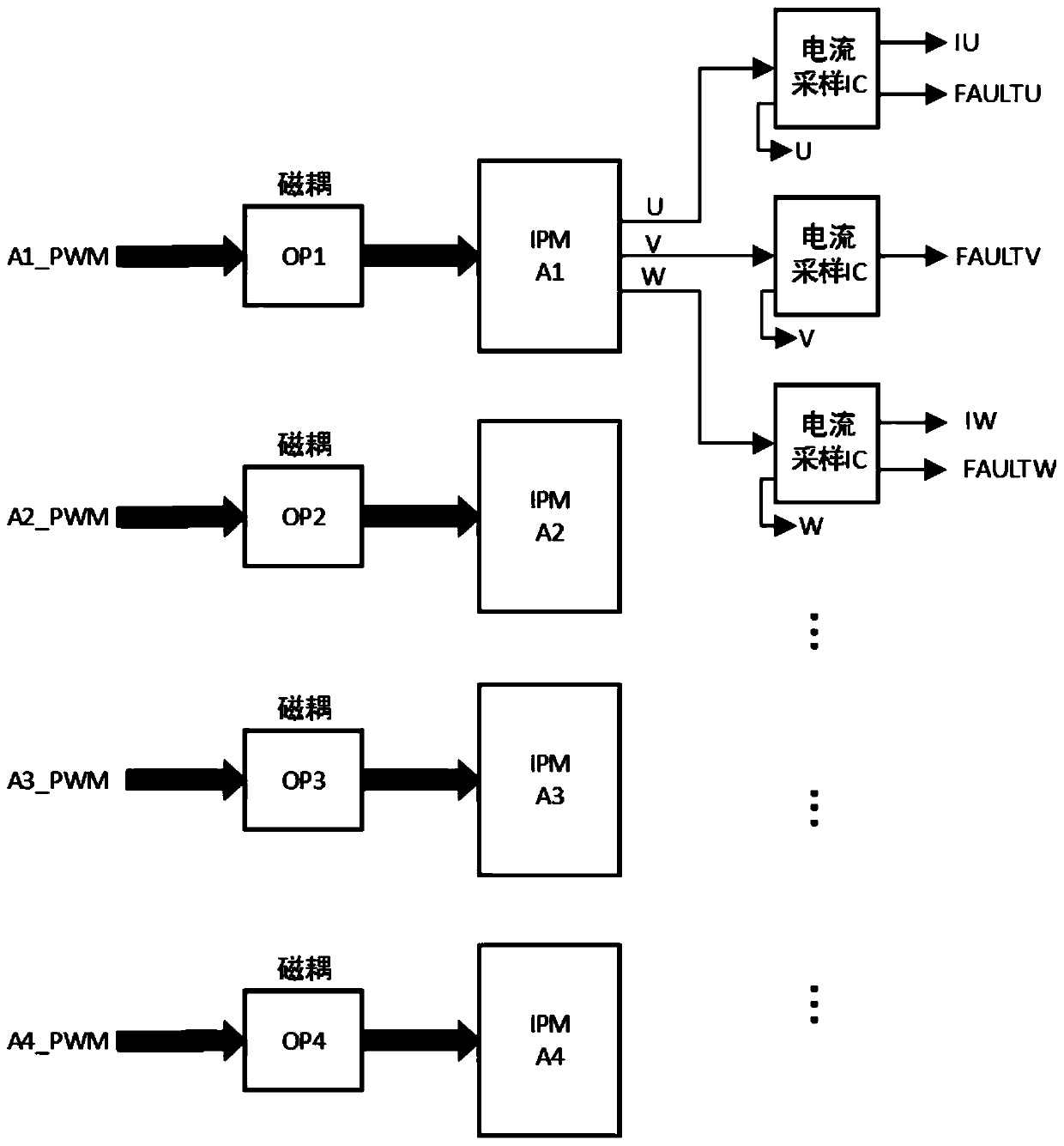

[0054] Such as figure 2 As shown, the power circuit includes a second substrate, a rectification and power soft-start module arranged on the second substrate, a power drive module, a voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com