Torque detector, and method for producing torque detector

A detector and substrate layer technology, which is applied in the direction of instruments, measuring devices, torque measurement, etc., can solve the problems of small gauge factor, difficult to detect strain, etc., and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

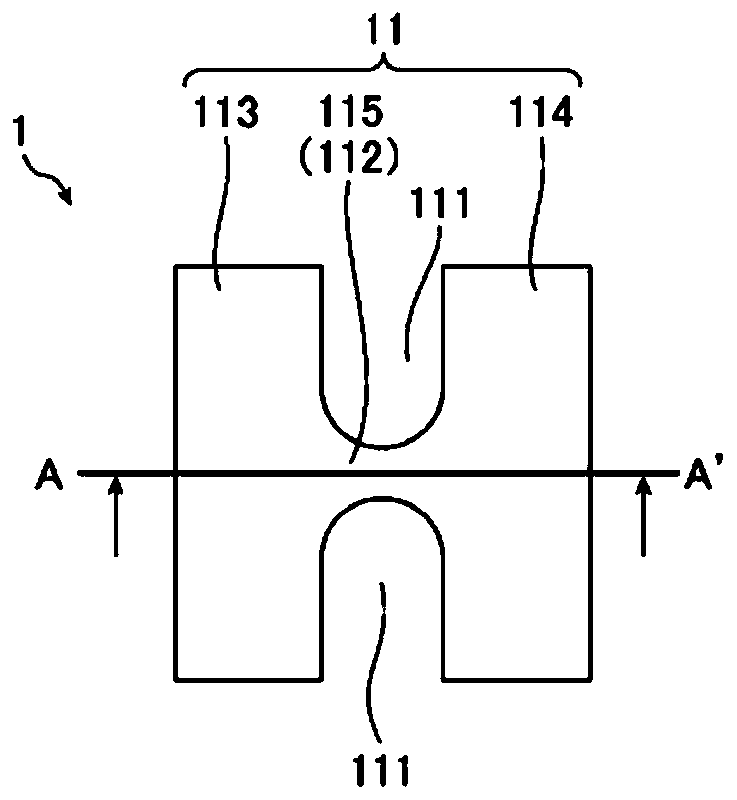

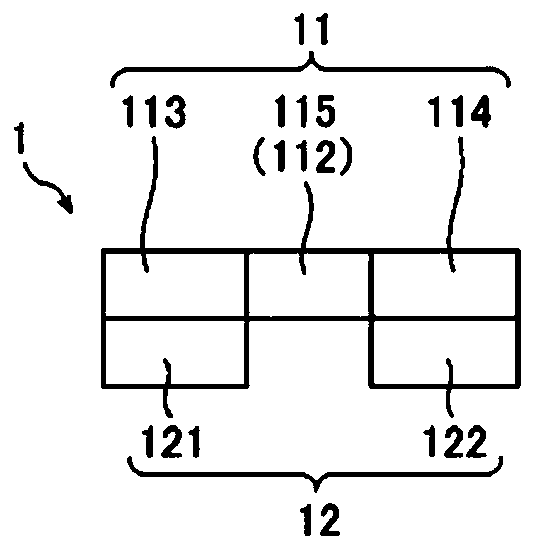

[0031] FIG. 1 is a diagram showing a configuration example of a torque detector according to Embodiment 1 of the present invention.

[0032] The torque detector detects the torque applied to the rotating shaft body 5 (see FIG. 4 ). One end of the rotating shaft body 5 in the axial direction is connected to a drive system 6 such as a motor, and the other end is connected to a load system such as a robot hand. As shown in FIG. 1 , the torque detector includes a strain sensor 1 .

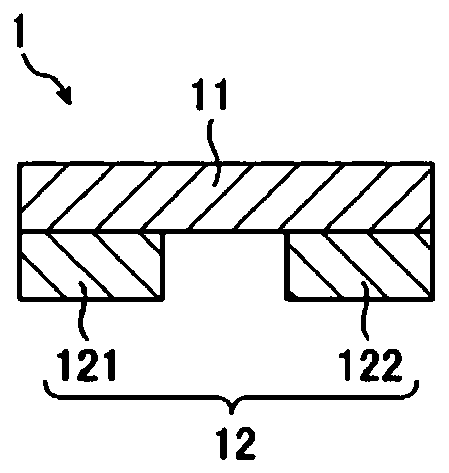

[0033] The strain sensor 1 is a semiconductor strain gauge that is attached to the rotating shaft body 5 and outputs a voltage corresponding to shear stress (tensile stress and compressive stress) from the outside. The strain sensor 1 is implemented by a micro-electromechanical system (Micro ElectroMechanical Systems, MEMS). As shown in FIGS. 1 and 2 , the strain sensor 1 includes a silicon layer (substrate layer) 11 and an insulating layer 12 .

[0034] The silicon layer 11 is single crystal silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com