Crop transplanting machine

A technology for transplanting machines and crops, applied in the field of transplanting machines, can solve problems such as unprotected soil clods and root systems, affecting crop yield and quality, and brittle soil clods, so as to reduce mutual damage, reasonable design, The effect of protecting the root system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

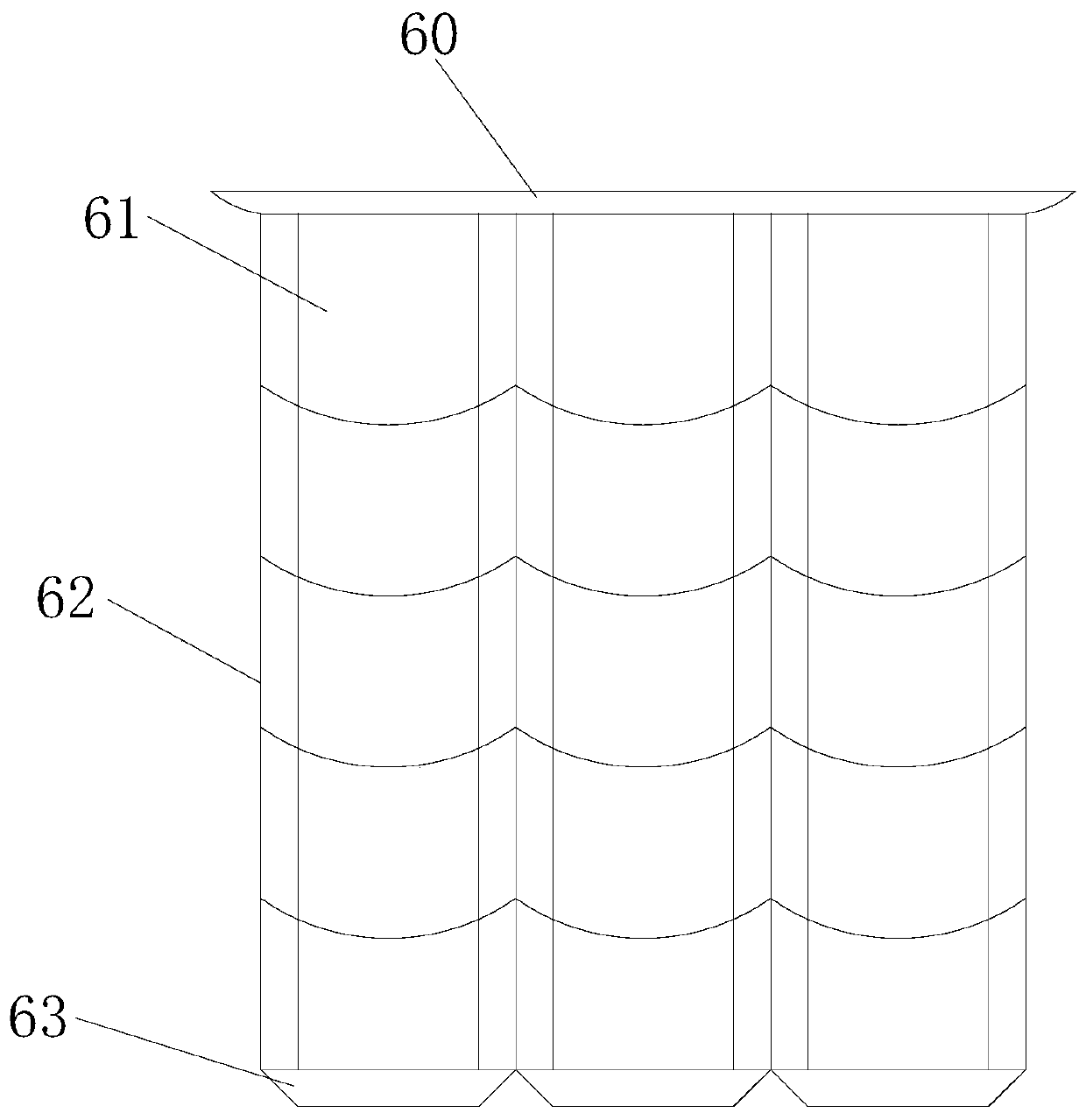

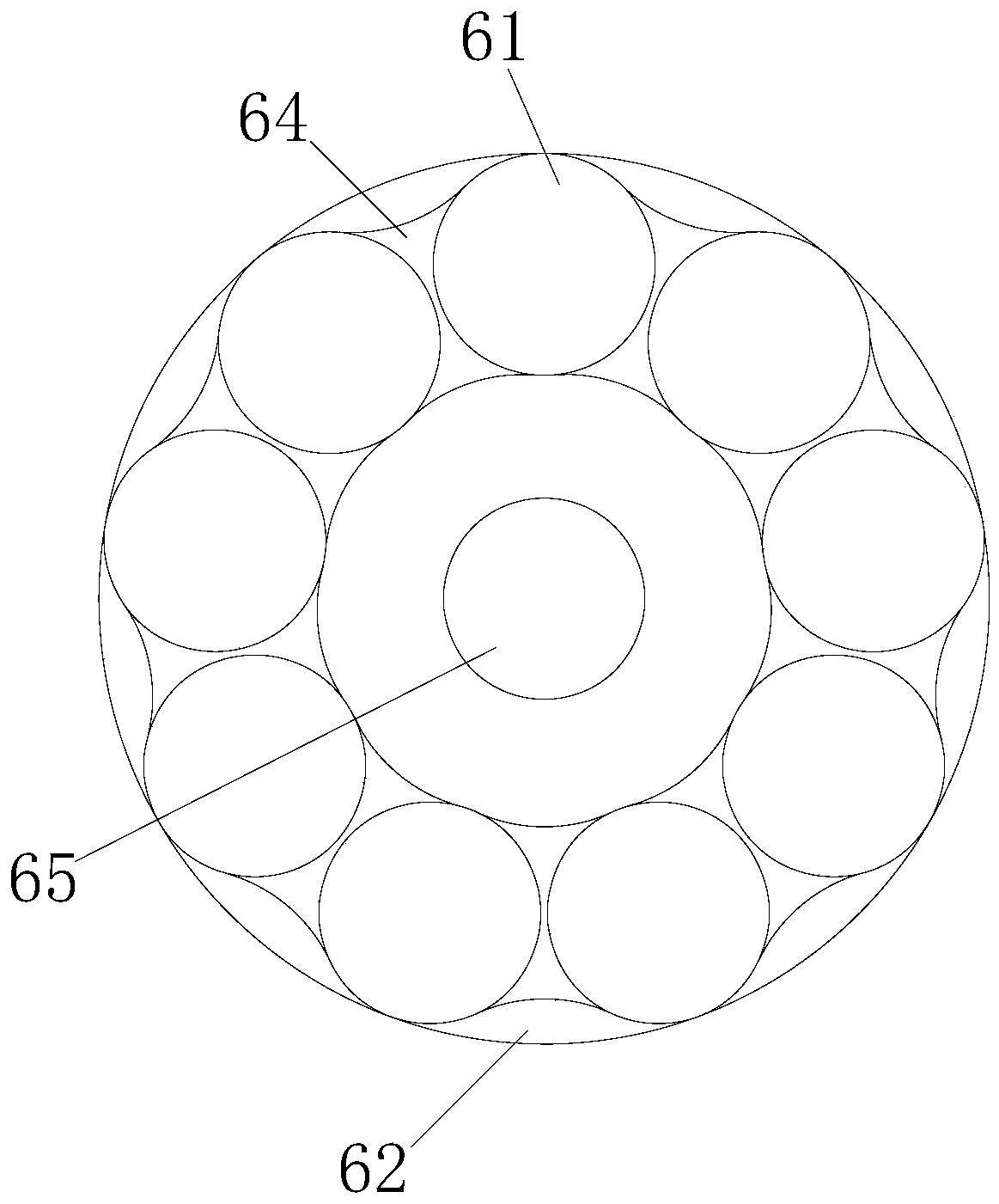

[0027] see Figure 1-Figure 6 , the present invention provides a kind of crop transplanting machine: its structure comprises the soil twisting drum 0, the front driving arm 1, the host supporting frame 2, the power starting wheel 3, the riding pile 4, the material storage box 5, the transplanting processing cylinder 6 The transplanting treatment cylinder 6 is vertically electric-welded on the top of the main machine support frame 2, and the two storage boxes 5 are respectively locked on the front and rear ends of the transplantation treatment cylinder 6 by rivets and communicate with each other. The front drive arm 1 is provided with two and is mechanically connected to the right side of the main frame 2, and the soil-opening winch 0 is located in the middle of the two front drive arms 1 and is movably connected with the main frame 2. The power starting wheel 3 is provided with two and is mechanically connected to the front and rear ends of the main frame 2, the riding pile 4 ...

Embodiment 2

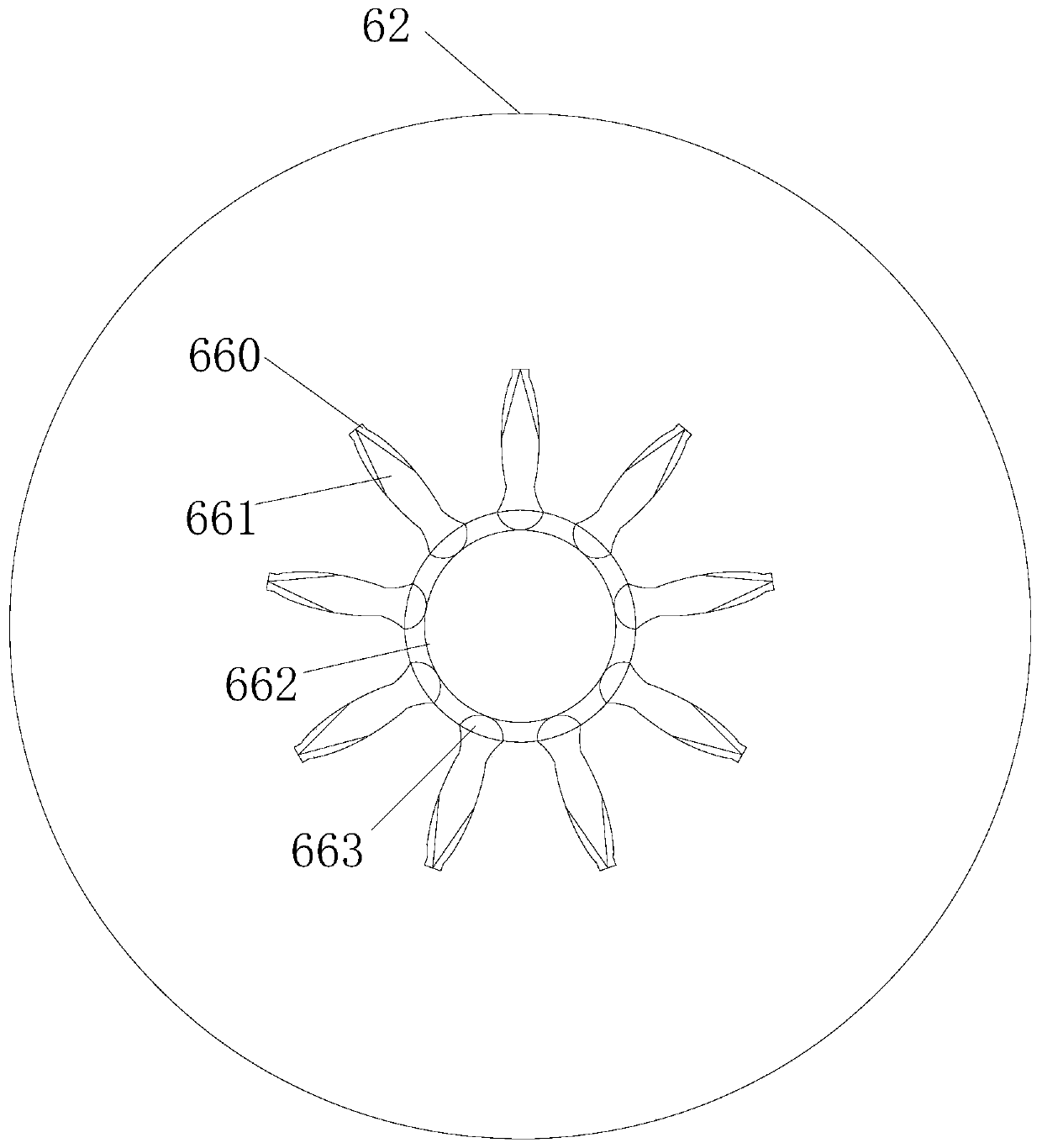

[0030] On the basis of Example 1, please refer to Figure 7 , the moisturizing structure 64 is composed of a central column 640, a water-receiving bag 641, a moistening soil mouth 642, a clamp frame 643, and a water-guiding strip 644. At the left and right ends of the interior, the central column 640 is vertically threaded in the middle of the two water-receiving bladders, and more than two water guide strips 644 are provided and inserted into the upper and lower ends of the central column 640. The soil moistening port 642 is set at the upper and lower ends of the inner side of the clamp frame 643 and communicates with the water guide bar 644. When the transportation process is far away, the soil clods attached to the crops tend to lose moisture and are more likely to be broken under vibration. Root system, in order to ensure the normal transplanting of crops, let the water bag 641 be connected to the water tank in the equipment, flow into the water guide strip 644 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com