Noodle pressing machine with automatic noodle shearing function

A noodle machine, automatic technology, applied in the direction of dough extruder, dough forming and cutting equipment, etc., can solve the problems of single function, inability to realize automation, troublesome operation, etc., and achieve the effect of avoiding excessive accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

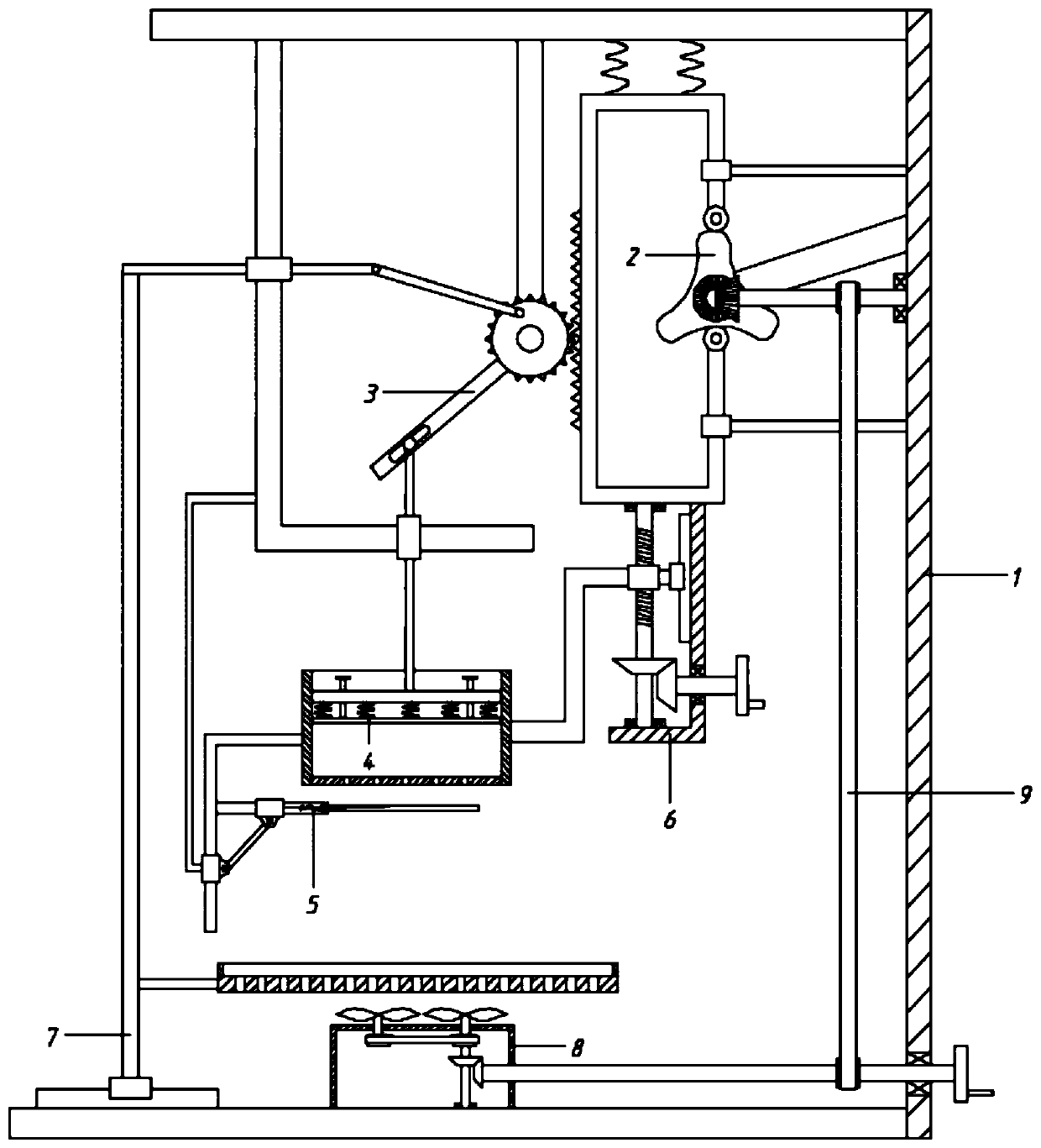

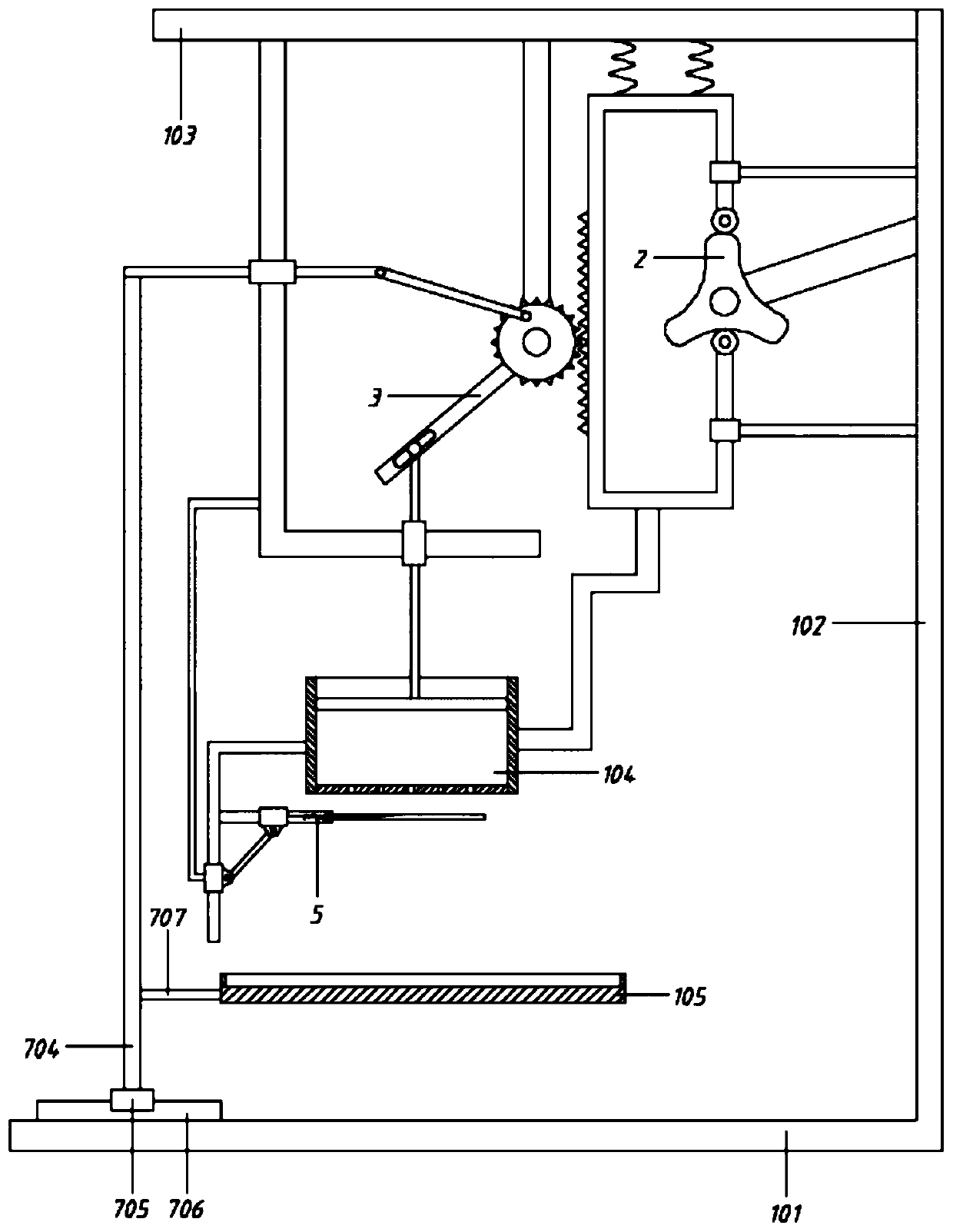

[0064] With reference to the accompanying drawings, a noodle pressing machine with automatic noodle cutting function includes a frame 1, a drive assembly 2, a noodle pressing assembly 3, a push-pull assembly 7 and a shearing assembly 5;

[0065] The frame 1 includes a bottom plate, a side plate 102, a top plate 103, a noodle-pressing barrel 104, and a joint box 105. The right end of the base 101 and the top plate 103 are fixed through the side plate 102, and the noodle-pressing barrel 104, the noodle box 105, and the base 101 are up and down in sequence. Setting; the upper left side of the side plate 102 is provided with a driving assembly 2, the left side of the driving assembly 2 is provided with a pressing assembly 3 and a push-pull assembly 7, the pressing barrel 104 is arranged at the bottom of the pressing assembly 3, and the left end of the connecting box 105 and the push-pull assembly The assembly 7 is connected; the right side of the noodle pressing bucket 104 is conne...

Embodiment 2

[0067] With reference to the accompanying drawings, a noodle pressing machine with automatic noodle cutting function includes a frame 1, a drive assembly 2, a noodle pressing assembly 3, a push-pull assembly 7 and a shearing assembly 5;

[0068] The frame 1 includes a bottom plate, a side plate 102, a top plate 103, a noodle-pressing barrel 104, and a joint box 105. The right end of the base 101 and the top plate 103 are fixed through the side plate 102, and the noodle-pressing barrel 104, the noodle box 105, and the base 101 are up and down in sequence. Setting; the upper left side of the side plate 102 is provided with a driving assembly 2, the left side of the driving assembly 2 is provided with a pressing assembly 3 and a push-pull assembly 7, the pressing barrel 104 is arranged at the bottom of the pressing assembly 3, and the left end of the connecting box 105 and the push-pull assembly The assembly 7 is connected; the right side of the noodle pressing bucket 104 is conne...

Embodiment 3

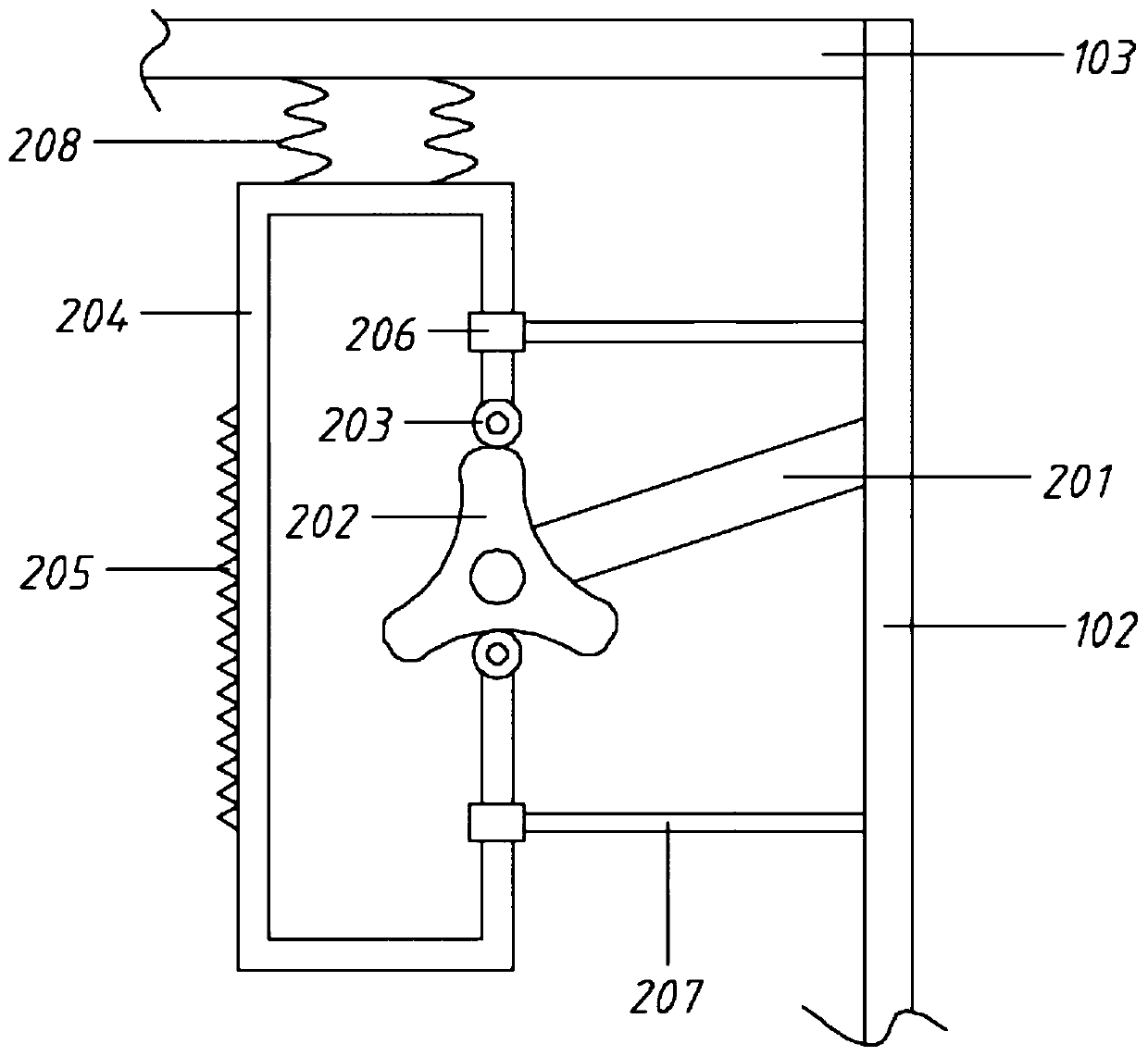

[0087] The difference from Embodiment 1 is that the left side of the noodle barrel 104 is connected with the adjustment assembly 6 through the No. 1 connecting rod 105;

[0088] The adjustment assembly 6 is arranged on the bottom end of the similar C-shaped rod 204, and includes a mounting frame 601, a No. No. 2 handwheel 608;

[0089] The mounting frame 601 is fixedly connected below the C-shaped rod 204; the screw mandrel 605 is installed on the mounting frame 601, and the upper and lower ends are respectively rotated to connect the C-shaped rod 204 and the mounting frame 601; the upper section of the screw rod 605 is screwed with a moving block 604, No. 2 slide block 603 is fixedly connected to the right side of moving block 604, and No. 2 slide rail 602 is installed correspondingly on mounting bracket 601, and No. 2 slide block 603 and No. 2 slide rail 602 are slidably connected; The rod 105 is connected with the left end of the moving block 604; No. 1 bevel gear 606 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com