A gel-type rigid contact lens lubricating fluid

A technology of lubricating fluid and contact lens, which is applied in the fields of drug combination, active ingredient of artificially synthesized polymeric materials, sensory diseases, etc., and can solve problems such as tear film unstable ocular surface, increased prevalence of dry eye, eye discomfort, etc. , achieve the effect of relieving dry eyes, improving hydrophobicity and eliminating stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

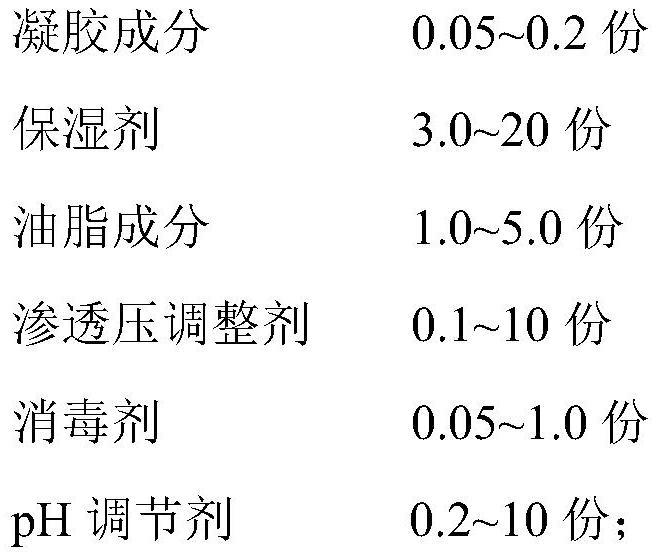

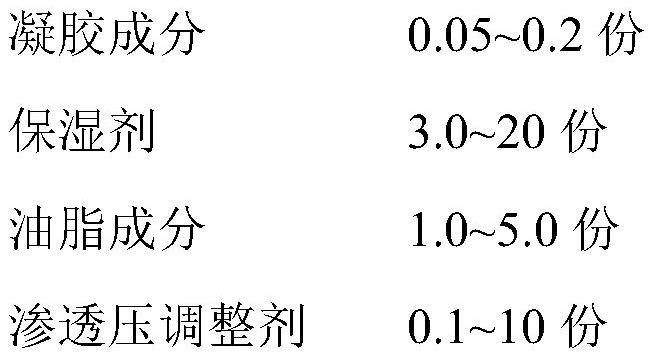

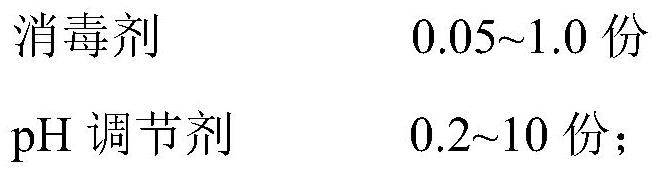

Method used

Image

Examples

preparation example Construction

[0027] The preparation process of above-mentioned lubricating liquid is as follows:

[0028] (1) Weigh the gel component and moisturizer, disperse them in the heated water for injection and stir, pre-dissolve for 40-60 minutes, stop stirring, after limited swelling for 1-2 hours, perform intermittent stirring, and cool to room temperature ;

[0029] (2) Weigh the pH adjuster, add it into the cooled mixed solution, and continue stirring until the pH value is adjusted to 5.0-8.0;

[0030] (3) Weigh the oil component, add it in the mixed solution after pH adjustment, stir and dissolve, weigh the disinfectant after completion, add it in the mixed solution after dissolving, stir and dissolve;

[0031] (4) Finally, weigh the osmotic pressure regulator, stir and dissolve until the osmotic pressure range is 240-290mOsm / kgH 2 O, in a sterile environment, the lubricating liquid can be obtained by filtering and sterilizing, and subpackaging and storing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com