Waste gas exhausting and recycling device for anaesthesia machine for anesthesia department

A recovery device and anesthesia machine technology, applied in the field of medical equipment, can solve problems such as difficulty in popularization, influence on exhaust, accumulation of impurities, etc., and achieve the effects of avoiding exhaust gas discharge, improving contact efficiency, and improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

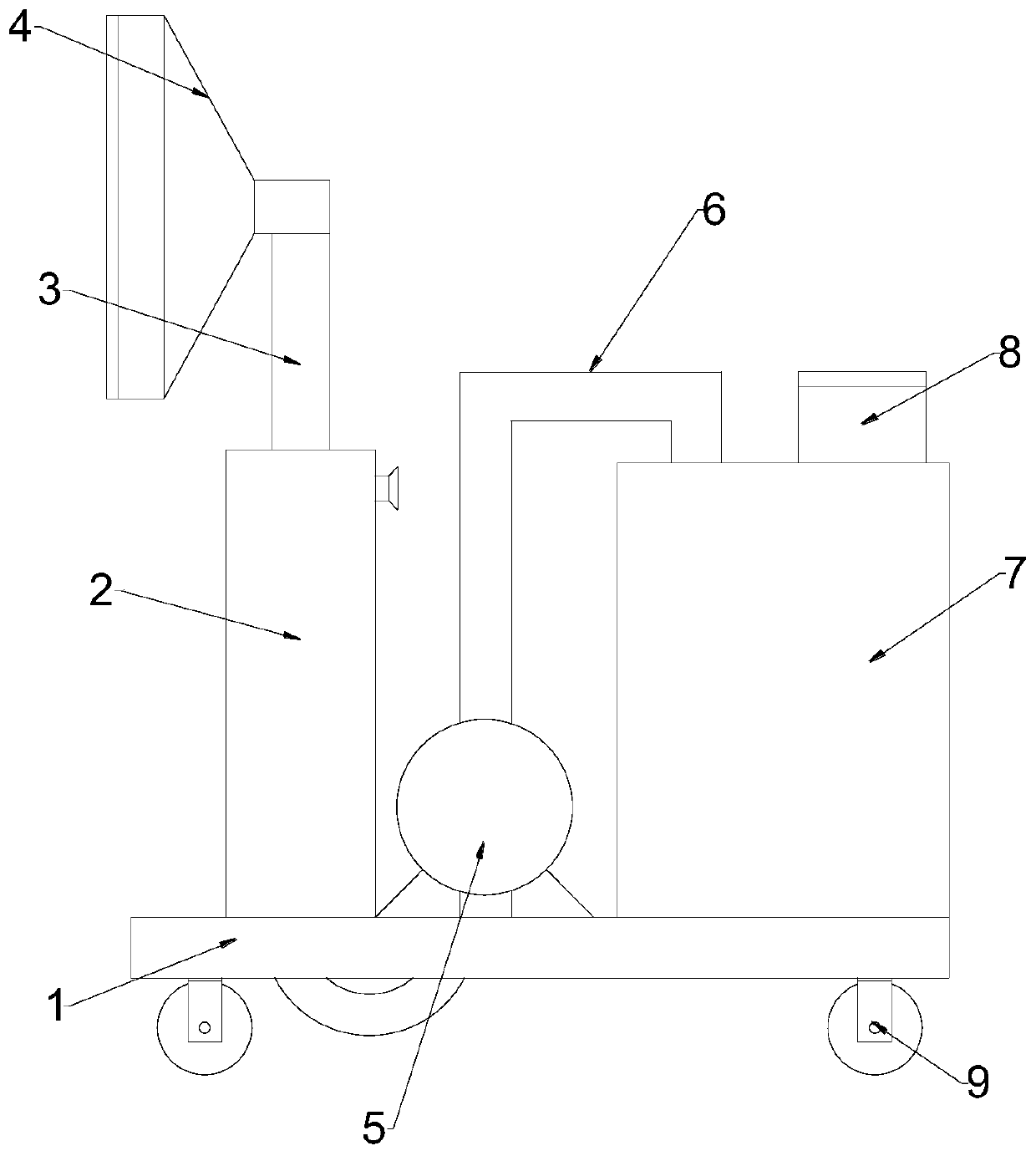

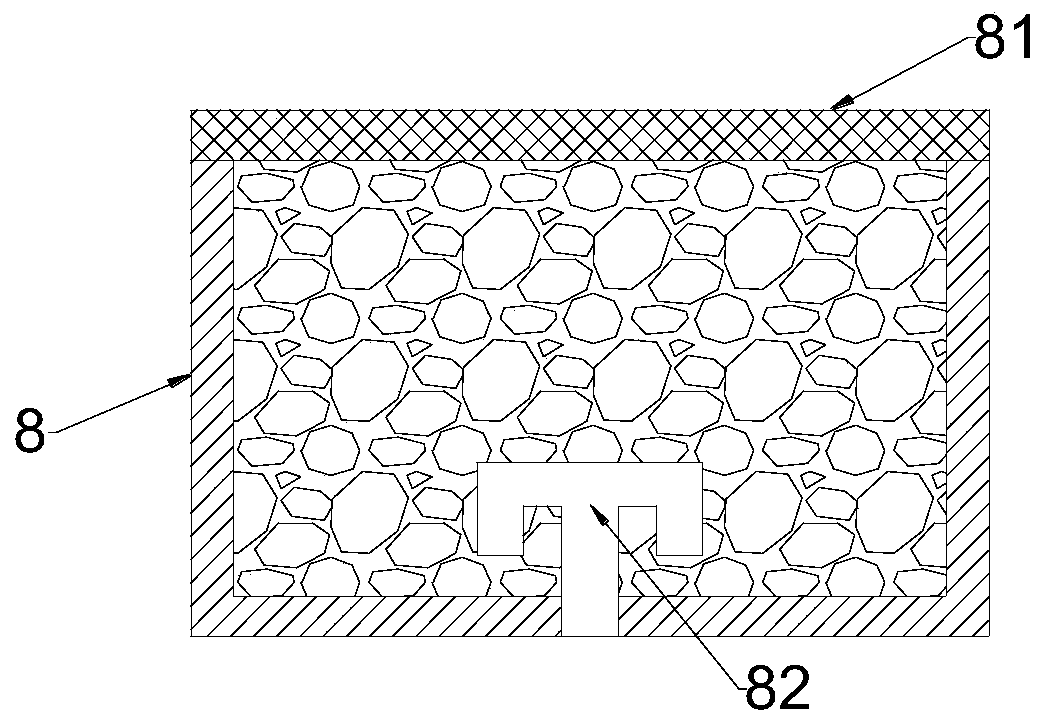

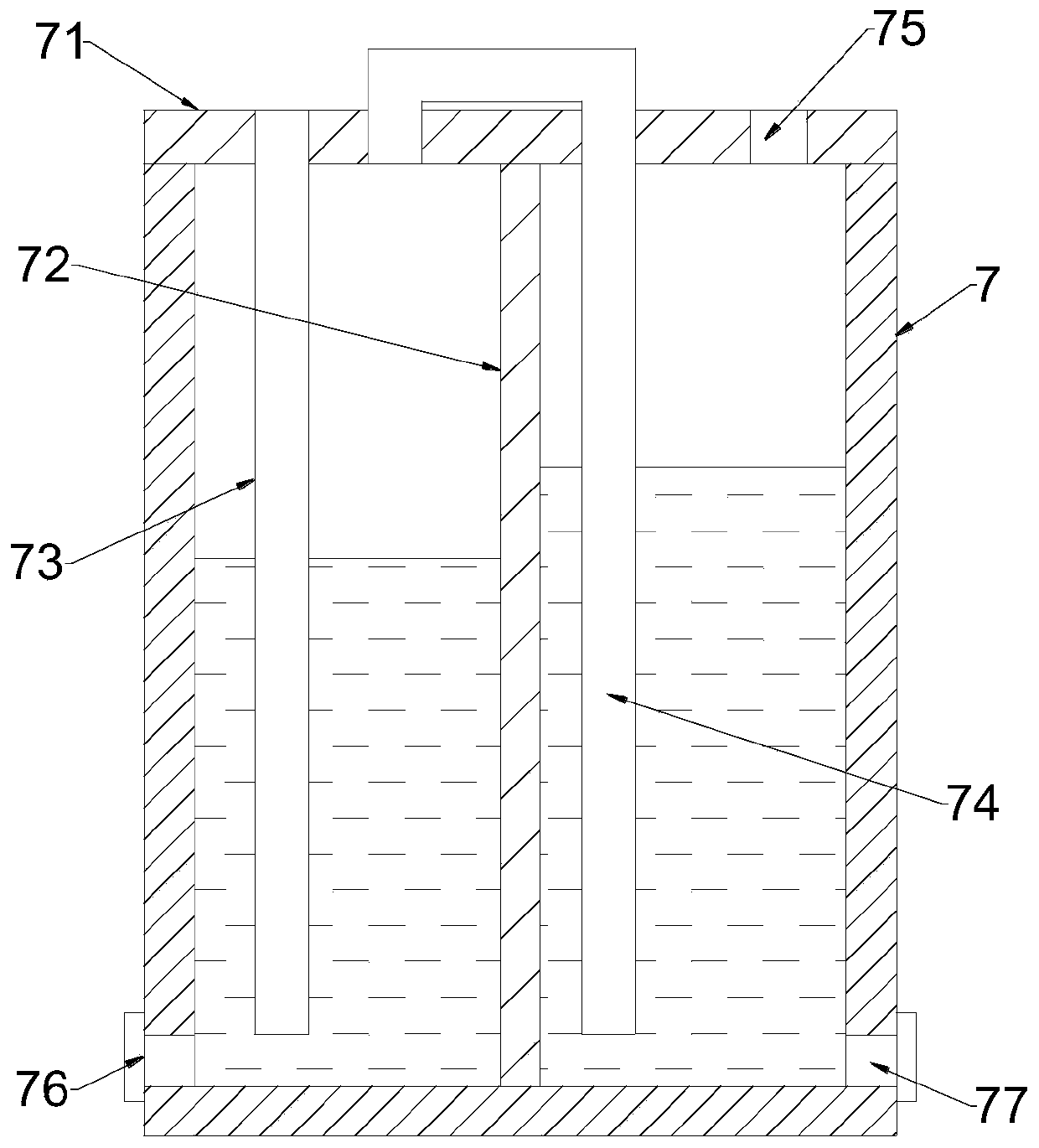

[0026] see Figure 1~3 , in an embodiment of the present invention, an anesthesia machine waste gas extraction and recovery device for anesthesia departments includes a suction mechanism for suction and a cleaning mechanism for treating exhaust gas, and the extraction mechanism and cleaning mechanism are both placed on the On the bottom plate 1 , the detachment mechanism communicates with the cleaning mechanism through the air pump 5 , and the detachment mechanism is slidably arranged on the support cylinder 2 .

[0027] Described detachment mechanism comprises the suction hood 4 that is used to fit on the waste gas outlet of anesthesia machine, and described suction hood 4 is a cover-like structure, and the edge of described suction hood 4 is bonded and is provided with rubber washer; The corrugated pipe and the strut 3 communicate with the intake end of the air pump 5; the strut 3 is a through-pipe structure, the upper end of the strut 3 communicates with the end of the exha...

Embodiment 2

[0033] see Figure 4, in order to avoid anesthesia machine waste gas and impurities therein from accumulating at the outlet of the waste gas pipeline, in an embodiment of the present invention, an anesthesia machine waste gas extraction and recovery device for anesthesia departments, on the basis of embodiment 1, the air extraction The open end of the cover 4 is inlaid with a bracket 41, the middle part of the bracket 41 is rotatably connected with a rotating shaft 42, and the periphery of the rotating shaft 42 is fixed with a plurality of groups of fan blades 43, and the fan blades 43 are fixed on the rotating shaft by welding. 42, the surface of the fan blade 43 is fixedly connected with densely covered bristles 44, so that when the air pump 5 pumps air through the exhaust cover 4, the airflow drives the fan blade 43 to rotate through the rotating shaft 42, so that the fan blade 43 drives the bristles 44 to rotate continuously To clean the position of the exhaust gas outlet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com