Precoated sand mold for casting

A coated sand and mold technology, applied in the direction of manufacturing tools, casting equipment, casting molding equipment, etc., can solve the problems of displacement deviation, damage, product deformation, etc., to reduce the attachment area, reduce the adhesion force, enhance the firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

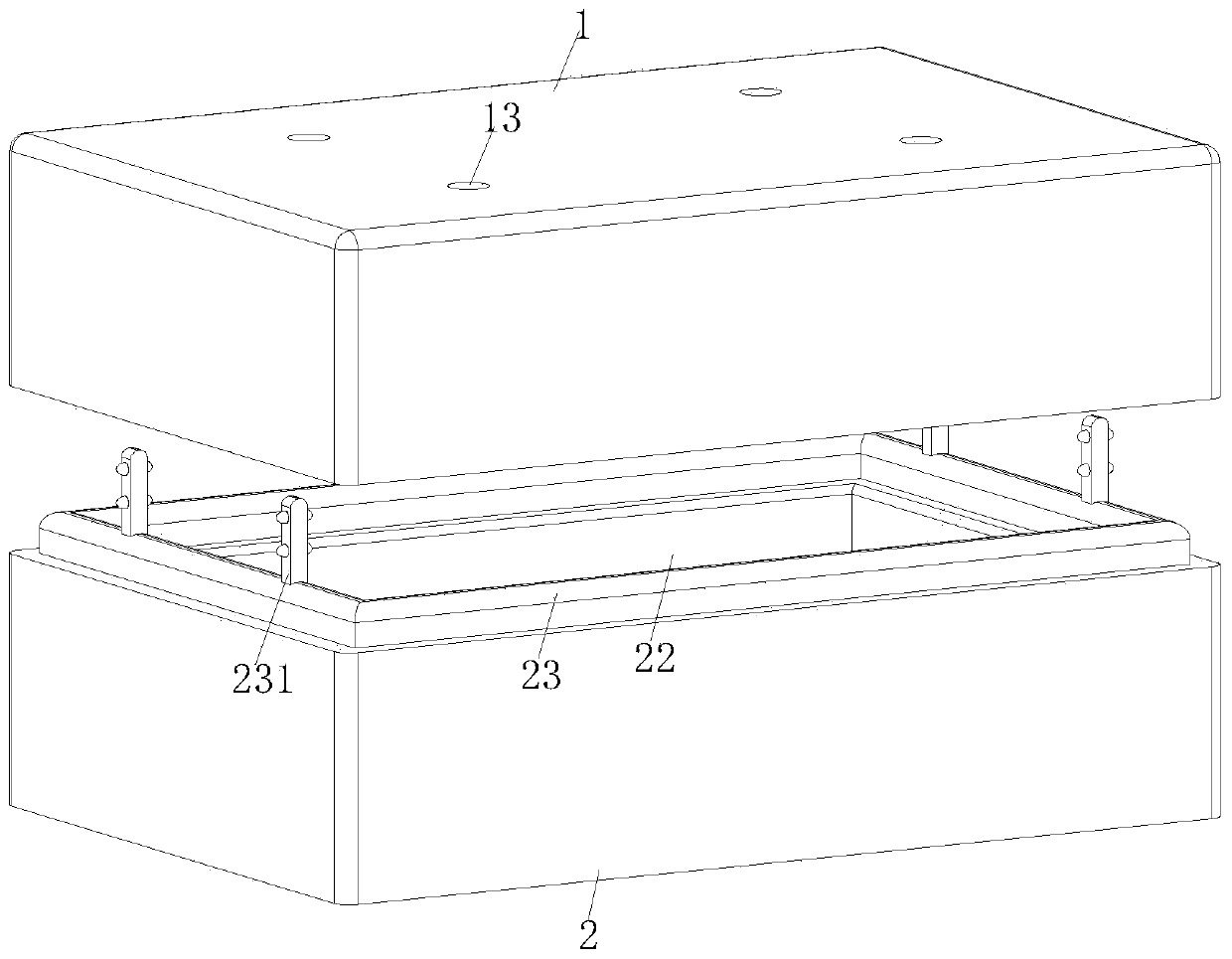

Method used

Image

Examples

Embodiment approach

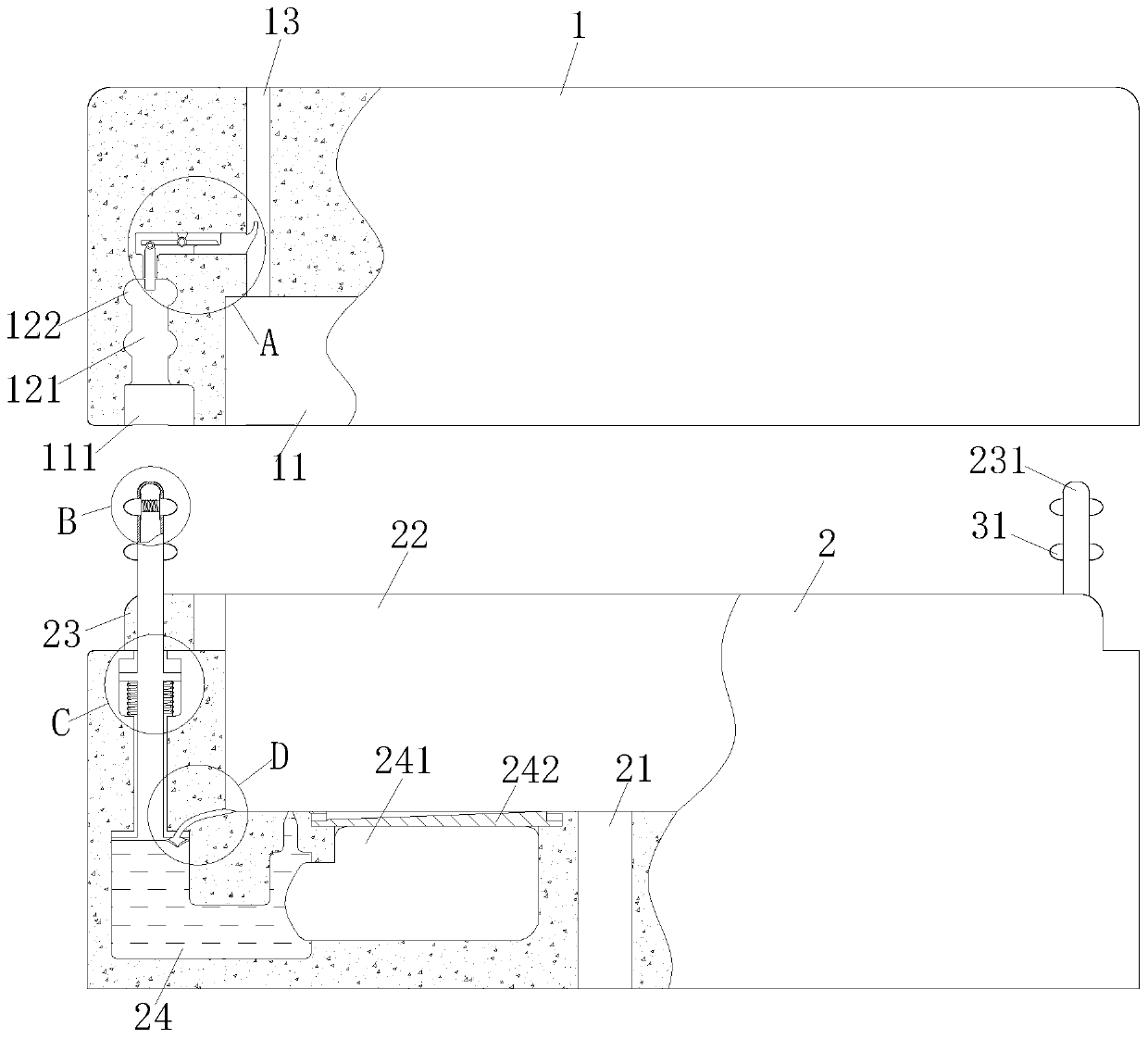

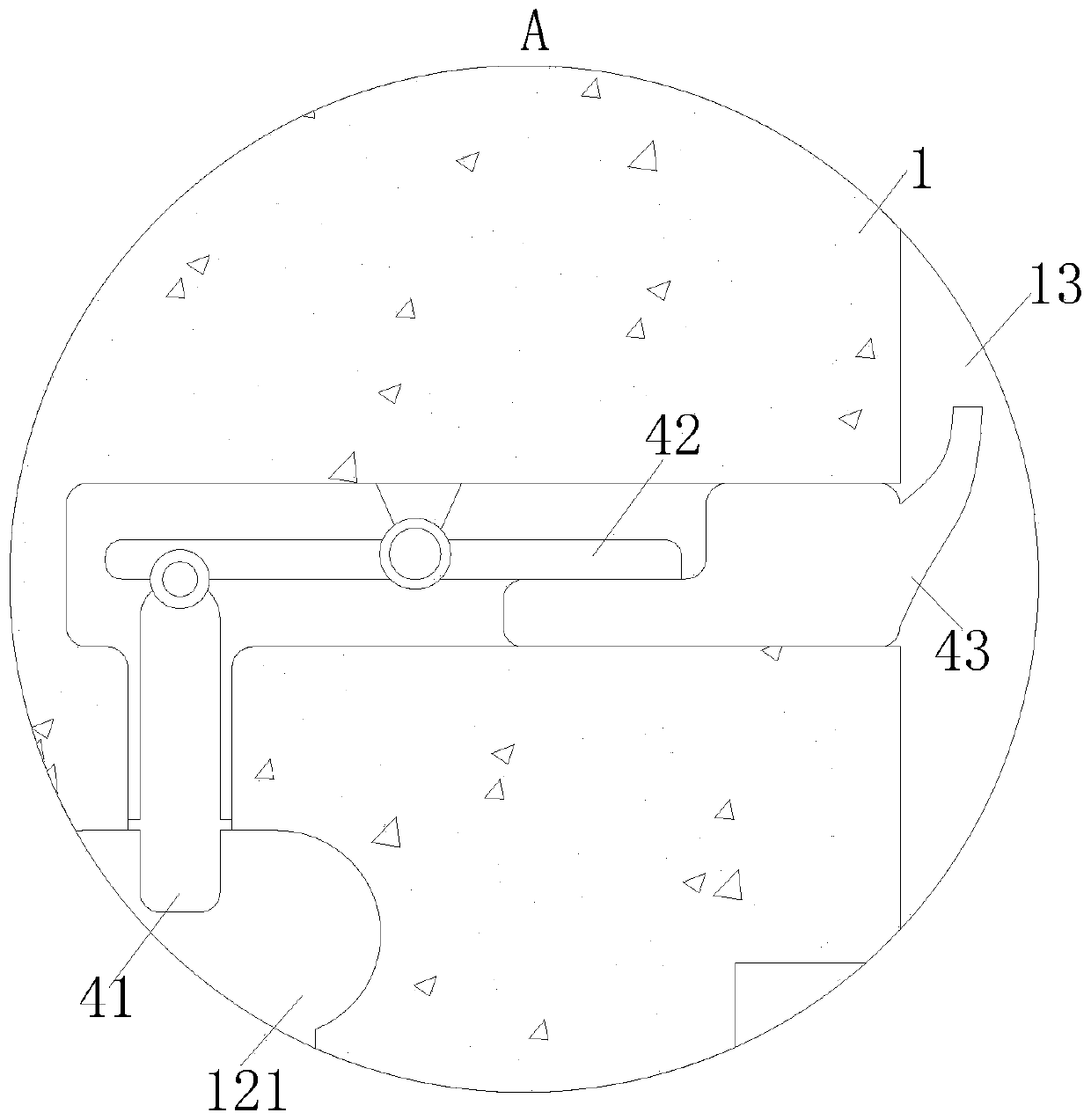

[0025] As a specific embodiment of the present invention, the positioning rod 231 is provided with a fastening unit 3; the fastening unit 3 includes a protrusion 31 and a No. 2 spring 32; Cavity 233, the protrusions 31 are symmetrically arranged in the first cavity 233, and the relative protrusions 31 are connected by the second spring 32; the side wall of the positioning hole 121 is provided with a semicircular card slot 122; through the fastening unit 3 and the card slot 122, to achieve a stable connection between the movable mold 1 and the fixed mold 2; when working, when the positioning rod 231 is stretched into the positioning hole 121, the protrusion 31 on the positioning rod 231 first extends into the positioning hole 121. In the slot 111, it is squeezed by the side wall of the positioning hole 121, and the protrusion 31 is squeezed into the first cavity 233. When the positioning rod 231 is fully inserted into the positioning hole 121, the protrusion 31 on the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com