A control method for the vertical lapping morphology of single-pass cladding layers manufactured by arc additive manufacturing

A single-pass cladding and additive manufacturing technology, which is applied in the field of additive manufacturing, can solve the problems of interlayer height and overlapping shape that are difficult to effectively control, and achieve good cladding layer vertical overlapping effect and high accuracy , Improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

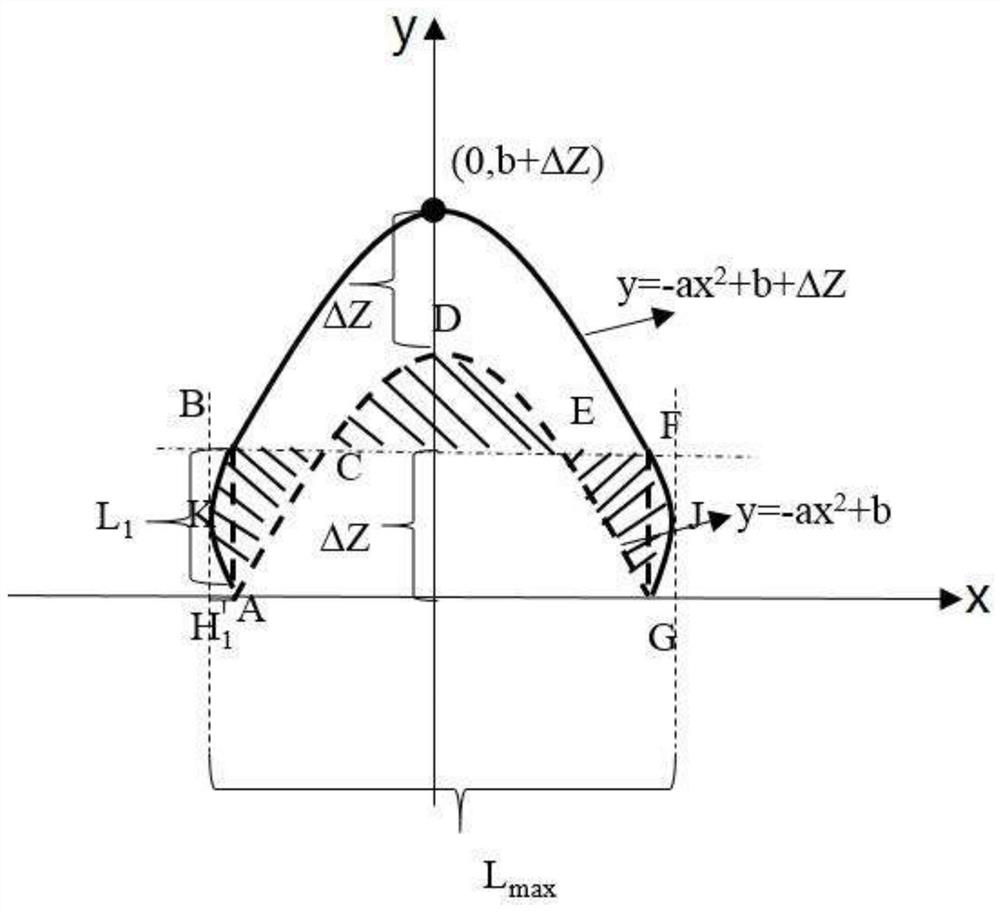

[0031] The invention discloses a method for controlling the vertical lap joint morphology of a single-pass cladding layer manufactured by arc additive manufacturing, which is specifically implemented according to the following steps:

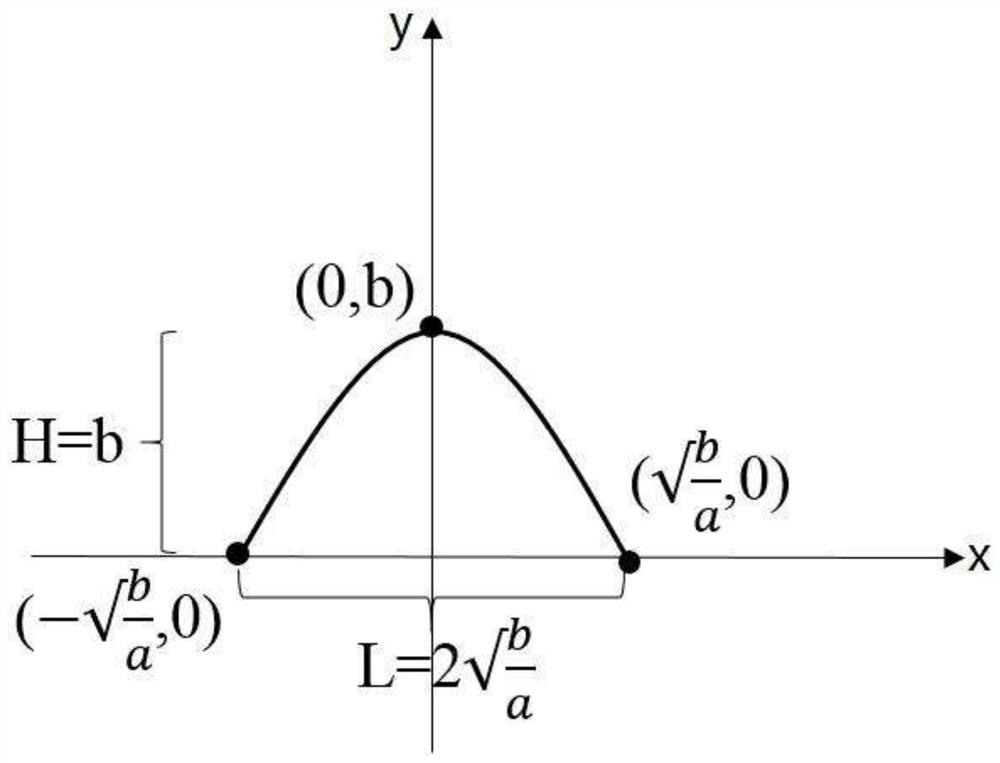

[0032] Step 1: Use electric arc to form the first cladding layer on the substrate, obtain the cross-sectional area of the middle region of the cladding layer, measure its width L in mm, measure its height H in mm, and measure at least 5 times , take the average value respectively, and obtain the parabolic fitting parameters of the cross-section of the first cladding layer as follows: a=4H / L 2 , b=H; then establish a parabolic model of the cladding layer;

[0033] like figure 1 As shown, the parabolic model of the cladding layer of the present invention is used to fit the profile of the cross-section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com