A Quantitative Horizontal Packing Machine

A packaging machine, horizontal technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as inability to guarantee accurate cutting, optimal product ratio packaging, and lower product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

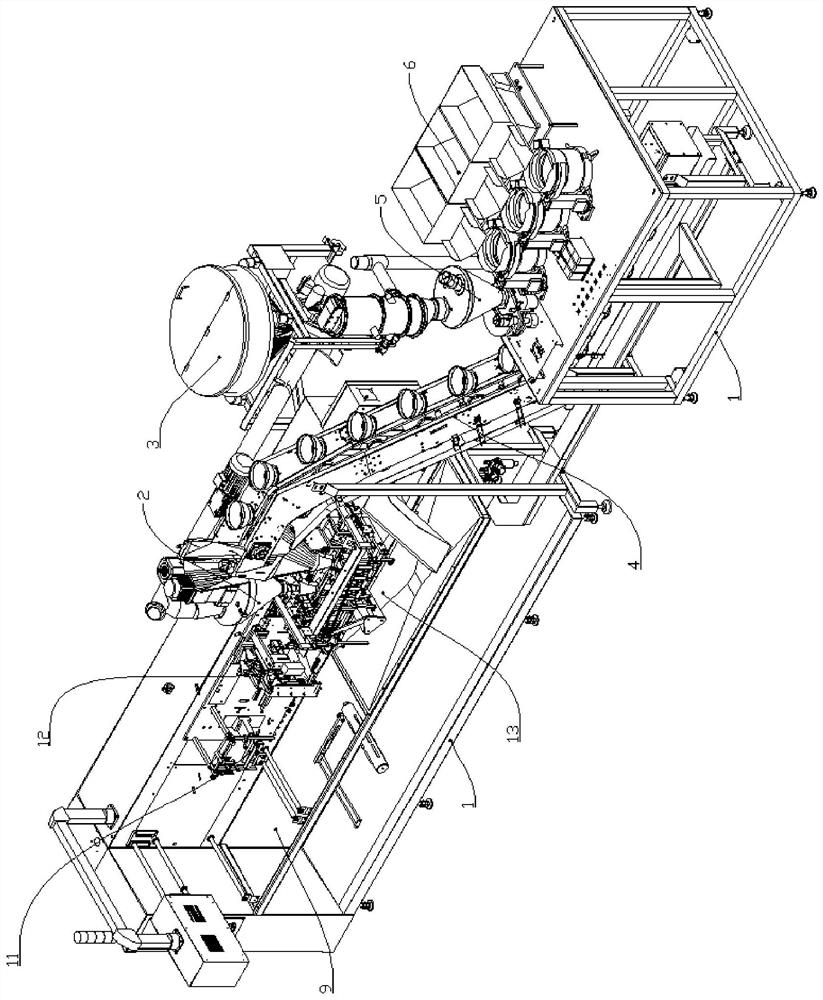

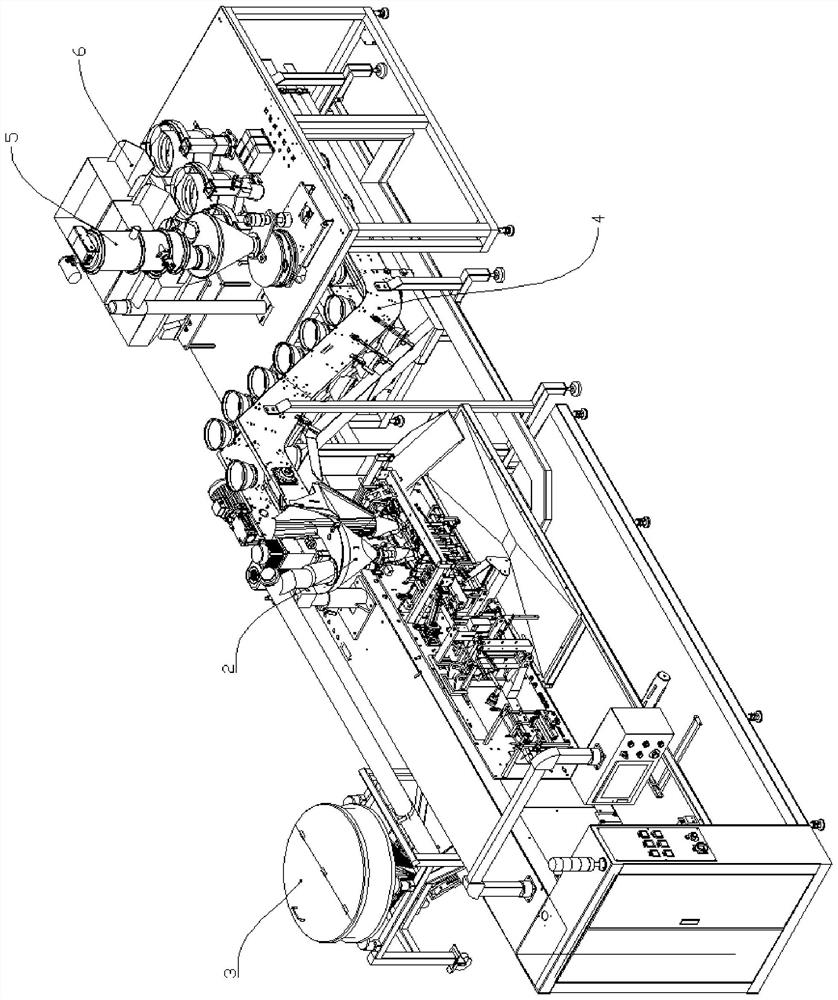

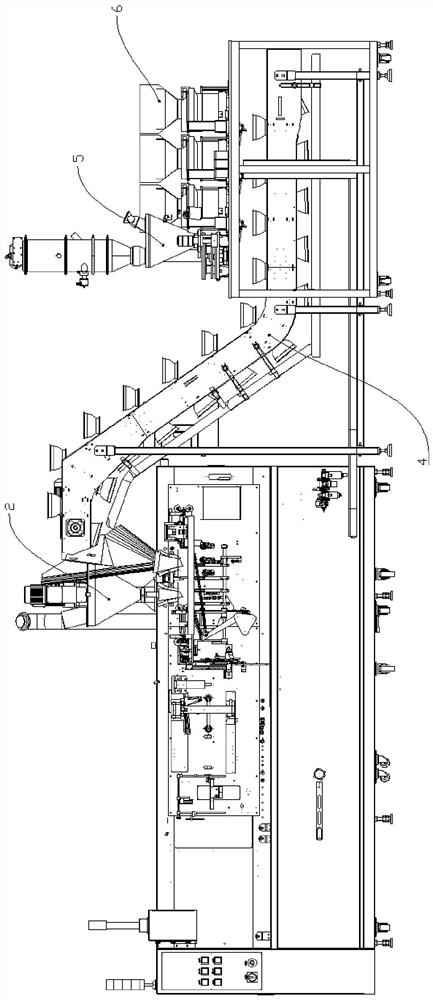

[0051] Such as Figure 1 to Figure 23 As shown, the present invention discloses a quantitative horizontal packaging machine, which includes a frame 1, on which a horizontal machine 9, a screw feeding mechanism 2, a bowl-type lifting mechanism 4, and a measuring cup feeding mechanism are sequentially fixed from left to right. Mechanism 5 and vibrating blanking mechanism 6, and frame 1 side is also fixed with screw lifting mechanism 3 and is connected with screw blanking mechanism 2, and screw lifting mechanism 3 comprises lifting bracket 302, and lifting bracket 302 is fixed with lifting hopper 301, and lifting hopper 301 bottom is connected with tapered bucket 303, also is fixed with lifting pipeline 304 on the lifting bracket 302, and one end of lifting pipeline 304 is connected with the bottom of conical bucket 303, and the bottom of the other end of lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com