Energy-saving container lining

An economical and lining technology, applied in the direction of internal accessories, lining/internal coating, etc., can solve the problems of company cost loss, large waste of material containers, high material cost, etc., to avoid difficult removal of vacuum and improve efficiency , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

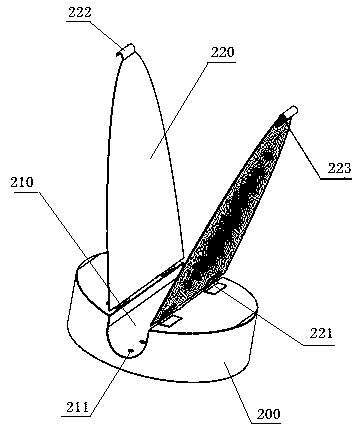

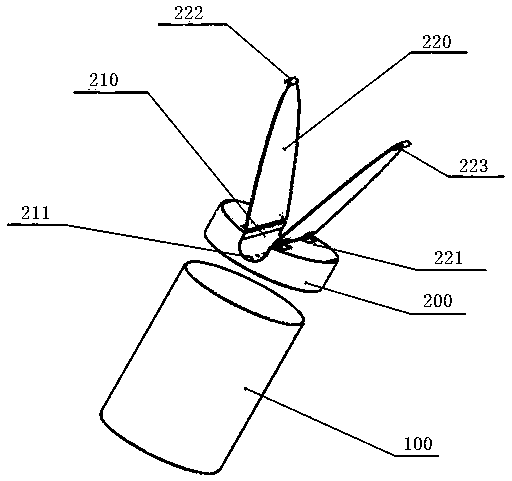

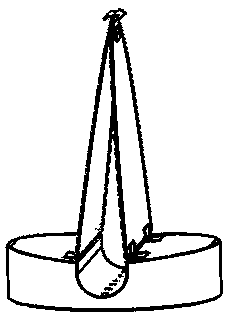

[0030] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

[0031] At present, liquid materials are often used in the wind power new energy industry, blade and tower manufacturing, large-volume product coating technology, and building exterior wall painting construction; when liquid materials are used in construction, such as often due to insufficient margin in the container, It is inconvenient to take out and has to be wasted. Even if some units manually collect the remaining amount in the container in order to save material costs, the efficiency and feasibility are very low, resulting in a large waste of raw materials, and most of the wasted materials are chemicals. The cost of product disposal is expensive, and the pollution to the environment is serious, which is a loss to the company's cost and a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com