Sealing equipment of liquid filling machine

A technology of sealing equipment and filling machine, which is applied in liquid processing, packaging, closures, etc., can solve problems such as complex structures, and achieve the effect of flexible contact and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

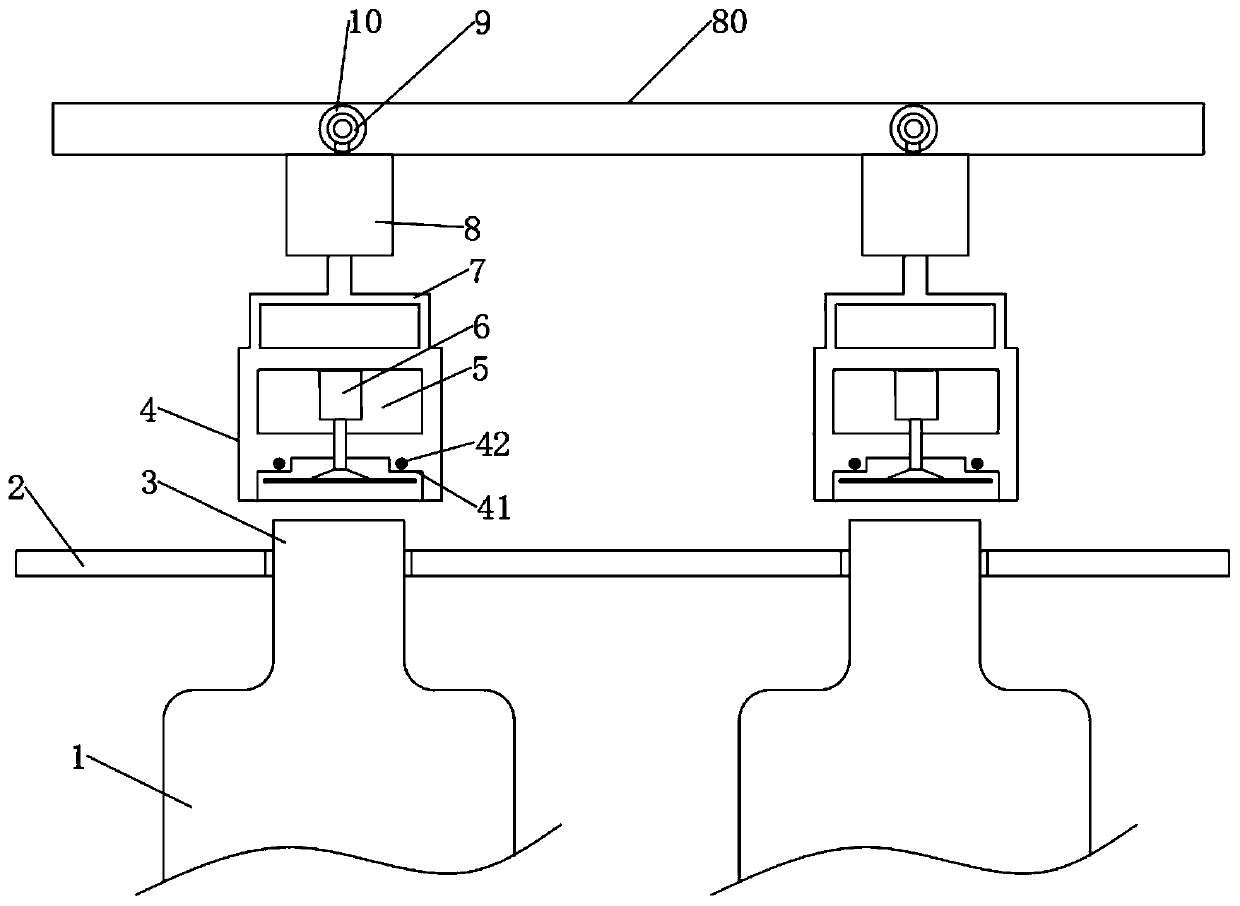

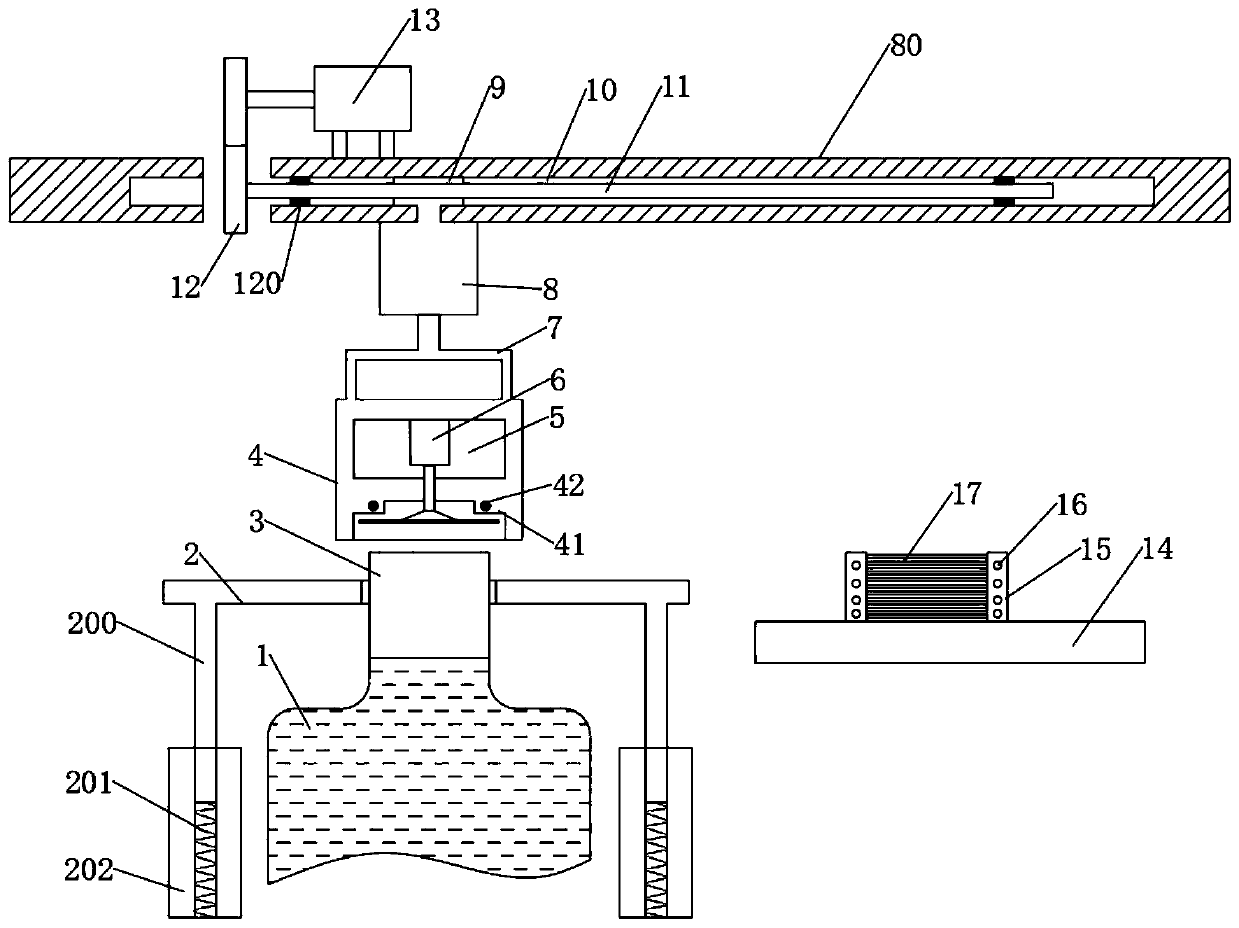

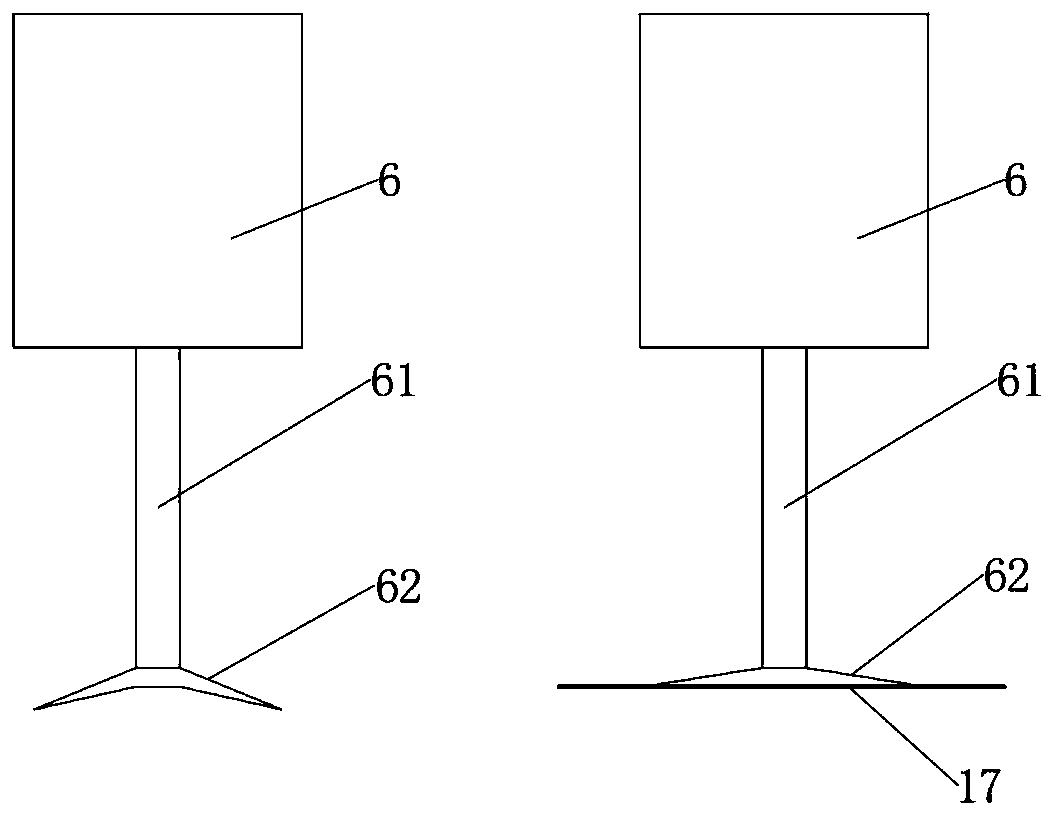

[0026] like Figure 1-4 As shown, a sealing device for a liquid filling machine includes a packaging frame 2, and plastic bottles 1 are uniformly placed in the packaging frame 2, and the bottle mouth 3 of the plastic bottle 1 is inserted into the packaging frame 2, and the bottle The upper side of the port 3 is provided with an encapsulation shell 4, the encapsulation shell 4 is fixedly connected with the mounting frame 7, the mounting frame 7 is connected with the pneumatic telescopic column 8, and the pneumatic telescopic column 8 is movably connected with the top plate 80. The pneumatic telescopic column 8 moves back and forth on the top plate 80, and the middle part of the packaging shell 4 is provided with a motor box 5, and the first motor 6 is arranged inside the motor box 5, and the first motor 6 and the telescopic rod 61 Connected, the end of the telescopic rod 61 is connected with a suction cup 62, the packaging shell 4 on the outer ring of the suction cup 62 is prov...

Embodiment 2

[0039] This embodiment is based on the embodiment 1 to specifically describe the working principle of a liquid filling machine sealing device shown in the embodiment 1.

[0040] A liquid filling machine sealing equipment, such as Figure 1-4 As shown, assemble.

[0041] After the equipment is assembled, start the second motor 13, so that the pneumatic telescopic column 8 moves to the right in combination with the sleeve 9. When the sleeve 9 runs to the end of the right stroke, the second motor 13 is suspended, and the first motor 6 is started, so that the telescopic rod The sucker 62 on the 61 moves downward to suck the film body 17 in the film tube 15. After sucking, the first motor 6 drives the sucker 62 back to the initial height.

[0042]Then the second motor 13 drives the screw rod 11 to make the pneumatic telescopic column 8 move to the left. When the packaging shell 4 returns to the top of the bottle mouth 3, the pneumatic telescopic column 8 moves down, and the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com