Induction automatic quenching device for surface treatment of chain plates

A technology of surface treatment and quenching device, applied in the direction of quenching device, heat treatment furnace, heat treatment equipment, etc., can solve the problems of unreasonable design and unoptimized structure, so as to reduce working intensity and workload, improve speed, and facilitate alternate replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

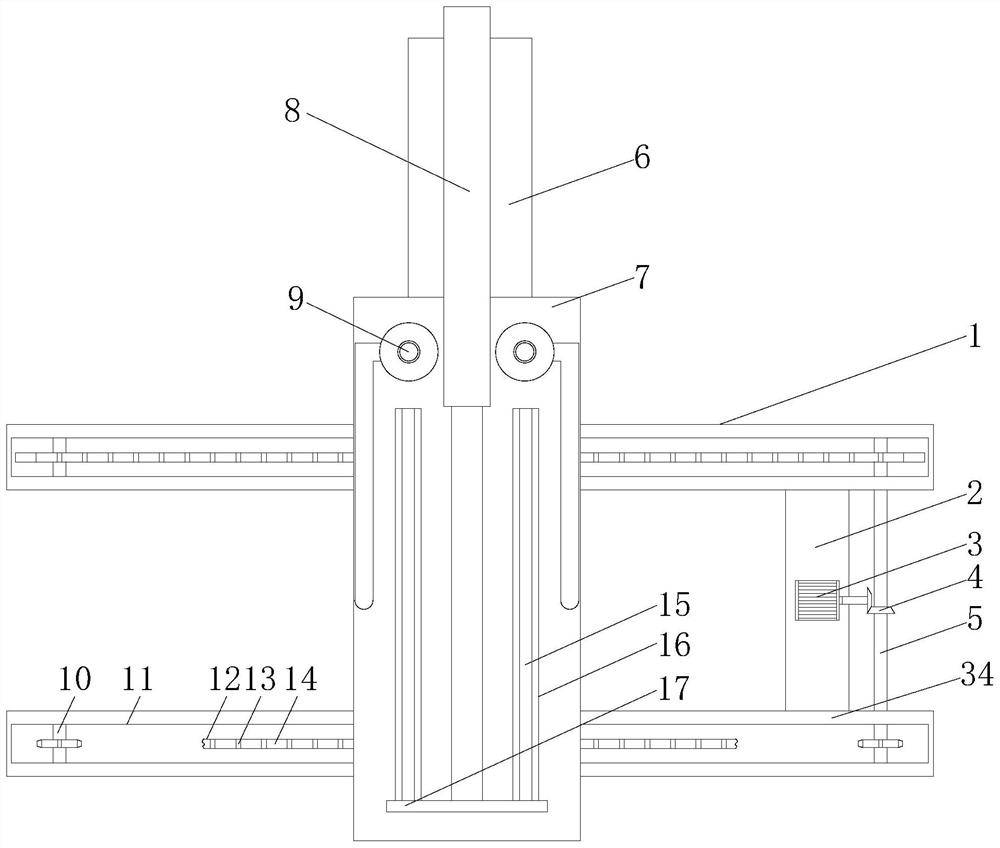

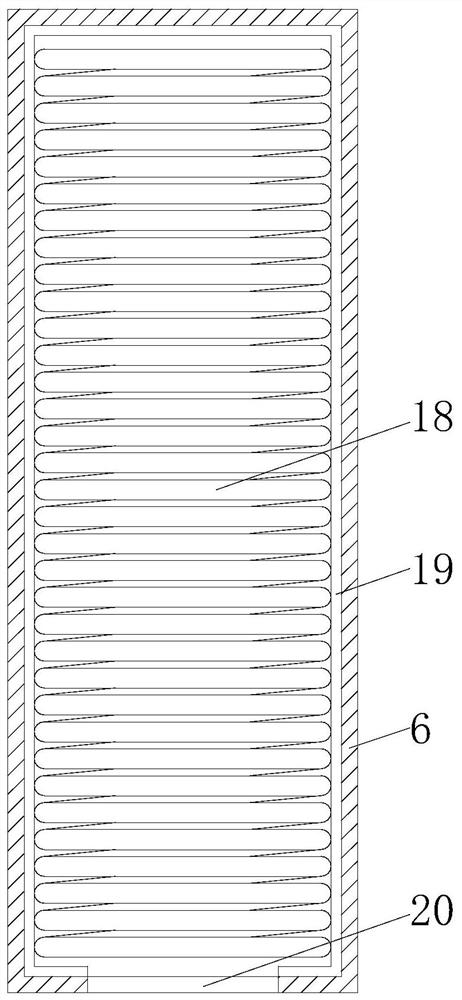

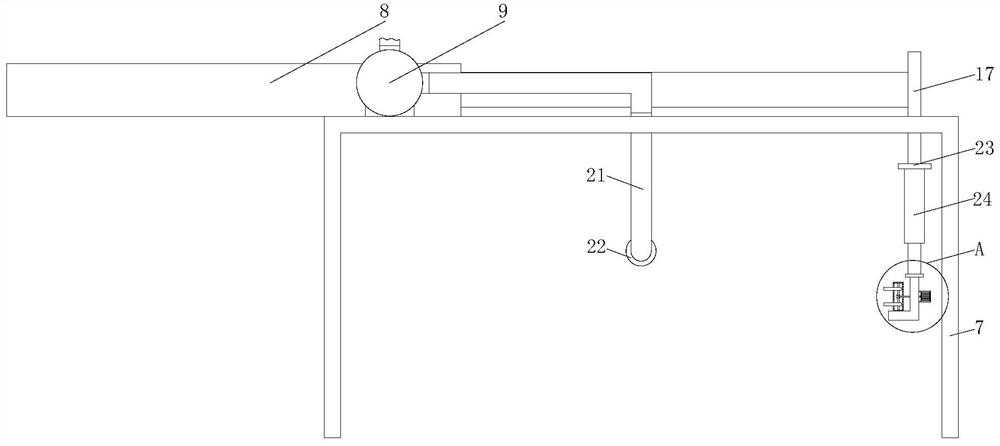

[0024] See Figure 1 ~ 4 , Embodiments of the present invention, the surface of the plate with one chain automatic induction hardening processing apparatus, comprising a conveying device quench chamber 7 and the bracket 6, the quenching chamber 6 through the front end surface 20 defines export, provided inside the quenching chamber 6 an induction heating coil 18, is fixedly connected to the inner wall of the quenching chamber 6 has insulation layer 19, on both sides of the through 7 are top bracket defines a first slide 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com