Construction method for obliquely downwards penetrating high-speed rail bridge through U-shaped frame structure

A frame structure and construction method technology, applied in infrastructure engineering, erection/assembly of bridges, bridges, etc., can solve problems such as high risk, long construction period, and impact on high-speed railway piers, so as to ensure operational safety, short construction period, and open shallow digging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The construction method of the U-shaped frame structure obliquely passing down the high-speed rail bridge provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

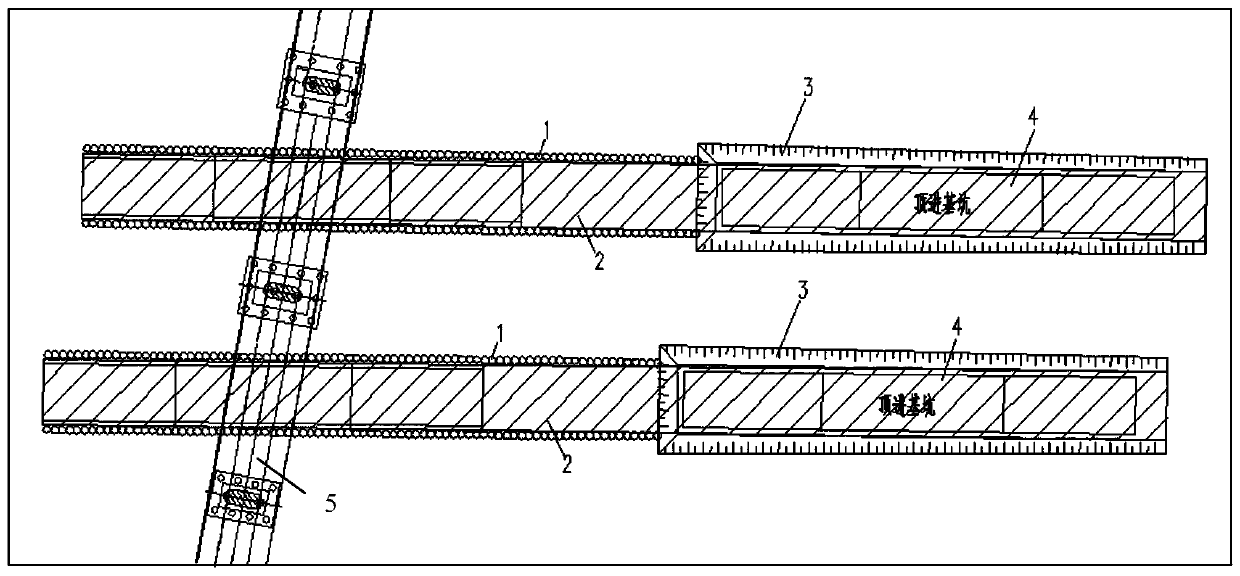

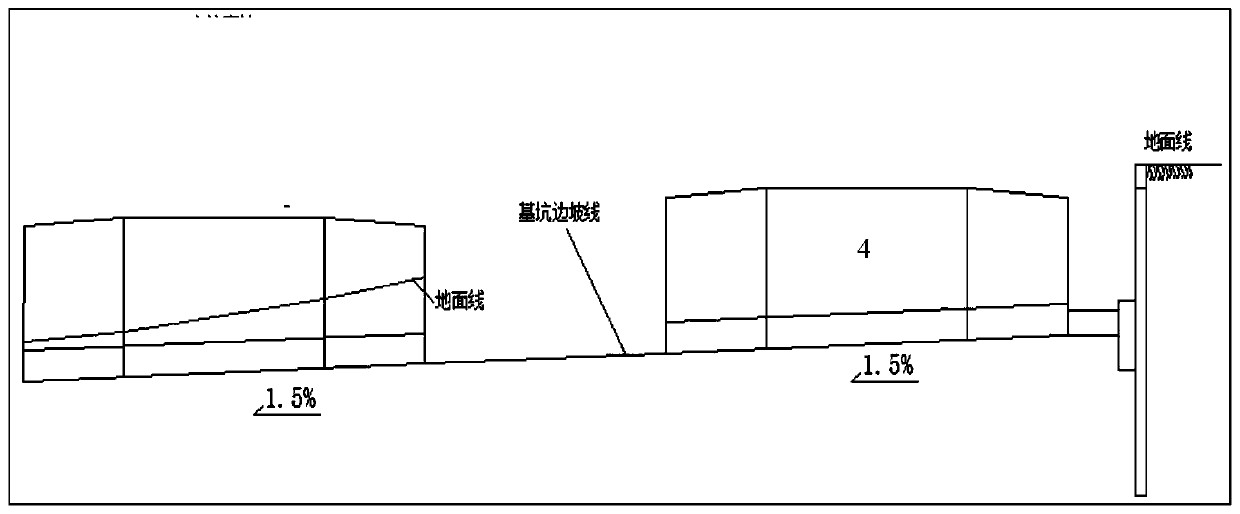

[0022] Such as figure 1 — figure 2 As shown, the construction method that the U-shaped frame structure provided by the invention obliquely passes down the high-speed rail bridge comprises the following steps carried out in order:

[0023] 1) Determine the position of the foundation pit 3 according to the design requirements in the foundation away from the high-speed rail bridge 5, and then set up a column on both sides of the U-shaped frame structure 4 under the high-speed rail bridge 5 from the foundation pit 3 to the jacking path 2 bored pile 1;

[0024] 2) Under the foundation pit 3 and on the path 2 of the U-shaped frame structure 4 to be jacked, high-pressure jet grouting piles are constructed to ensure the bearing cap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap