Roof deformation joint structure and construction method thereof

A construction method and deformation joint technology, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve condensation, not fully considering the influence of roof panel deformation, polyethylene round rods are easily crushed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

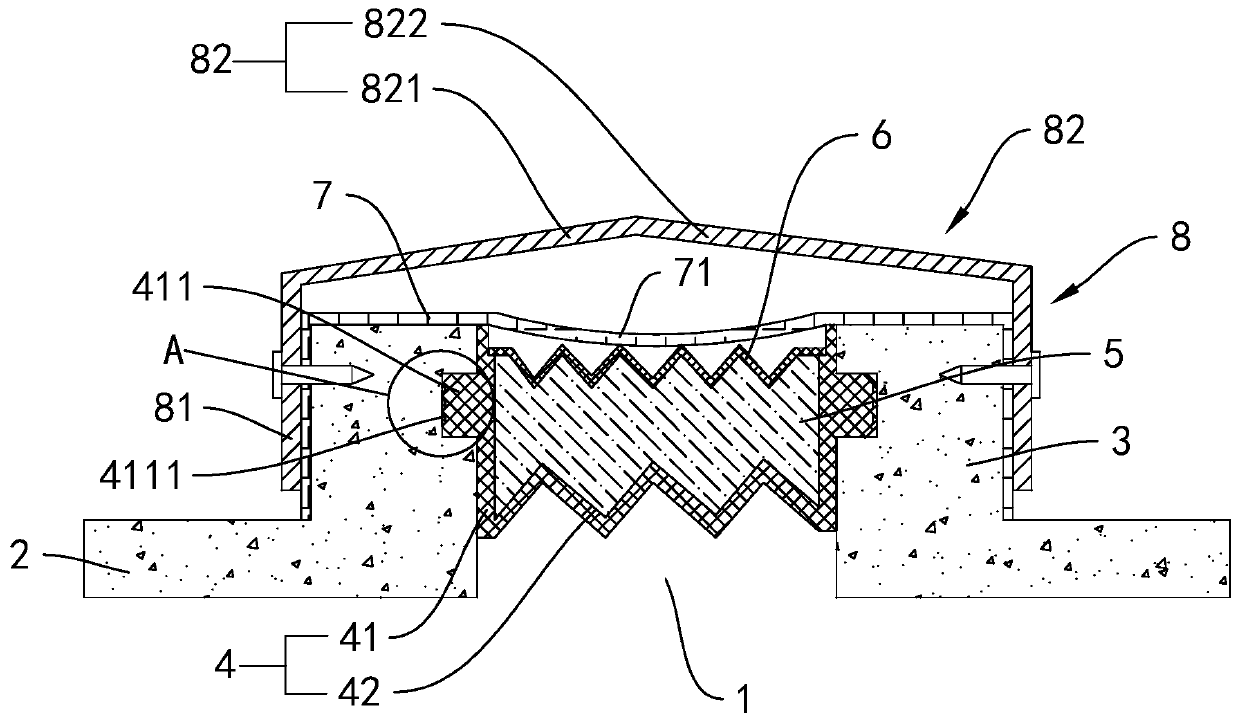

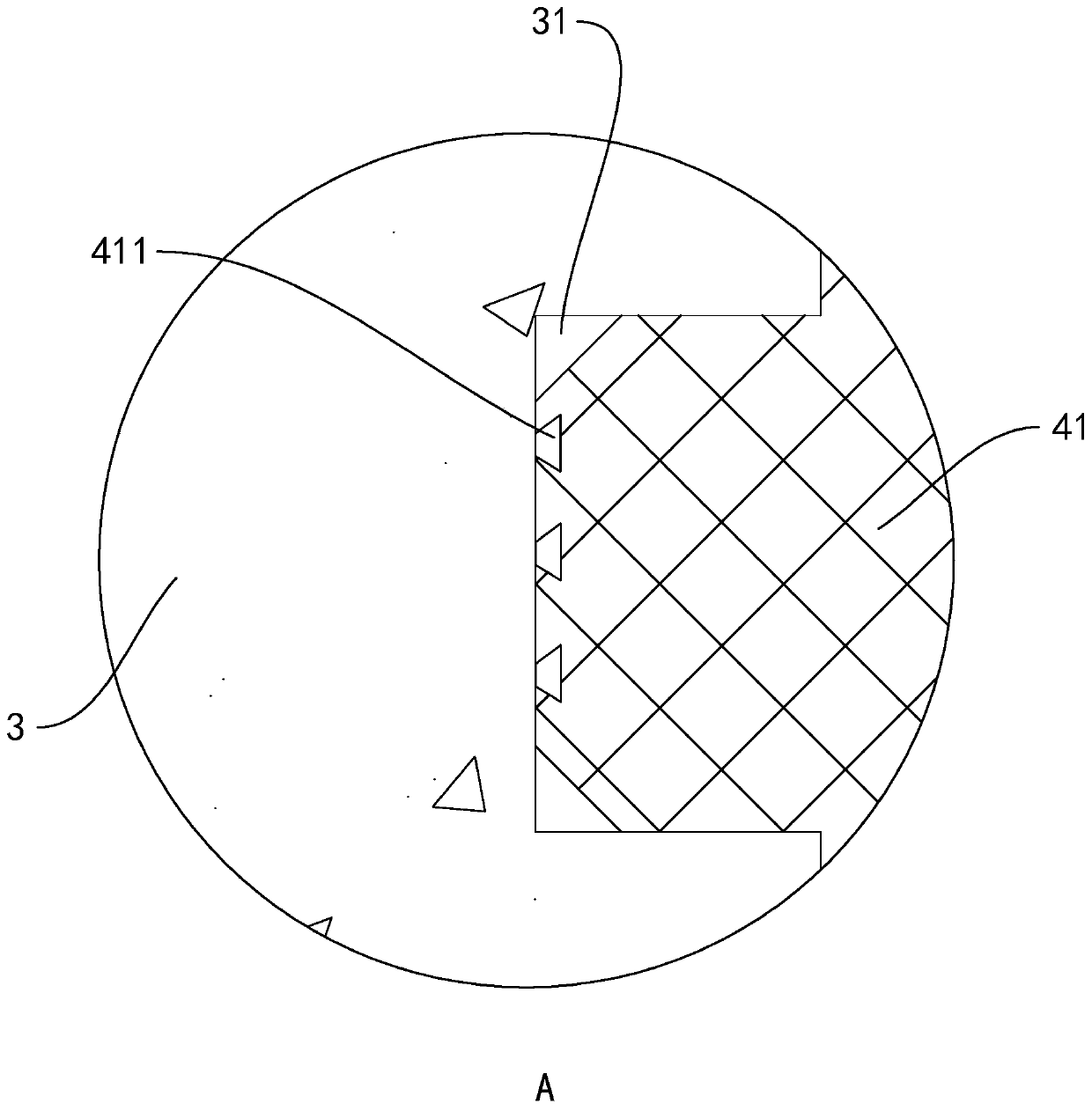

[0042] refer to figure 1 , is a roof deformation joint structure disclosed by the present invention, comprising a roof panel 2 with a deformation joint 1, and the top surface of the roof panel 2 is provided with bases 3 respectively located on both sides of the deformation joint 1, and the base 3 and the roof Panel 2 is integrally formed.

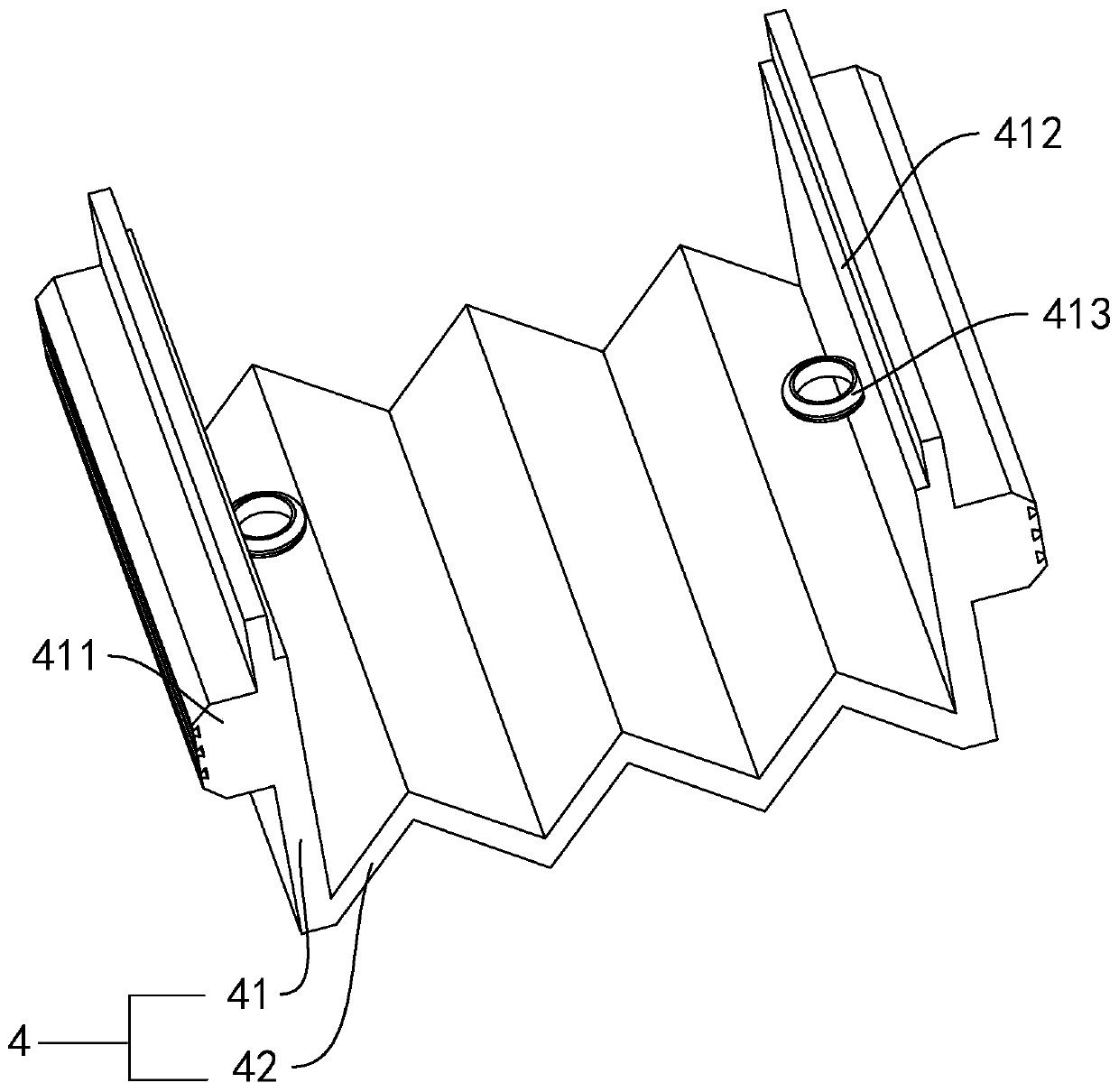

[0043] An elastic blocking member 4 is arranged between the two bases 3, and the blocking member 4 includes connecting plates 41 respectively attached to the opposite side surfaces of the two bases 3 and elastic parts between the connecting plates 41. The expansion and contraction part 42 is arranged along the width direction of the deformation seam 1 in the expansion and contraction direction of the elastic expansion and contraction part 42 . The elastic telescopic part 42 is integrally formed with the two connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com