Intake and exhaust rotary valve of internal combustion engine

An internal combustion engine intake and exhaust, rotary valve technology, applied in the direction of rotary slide valve, valve details, valve device, etc., can solve the problems of many parts, large occupied volume of internal combustion engine, complex structure layout, etc., to save parts and structure Simple, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

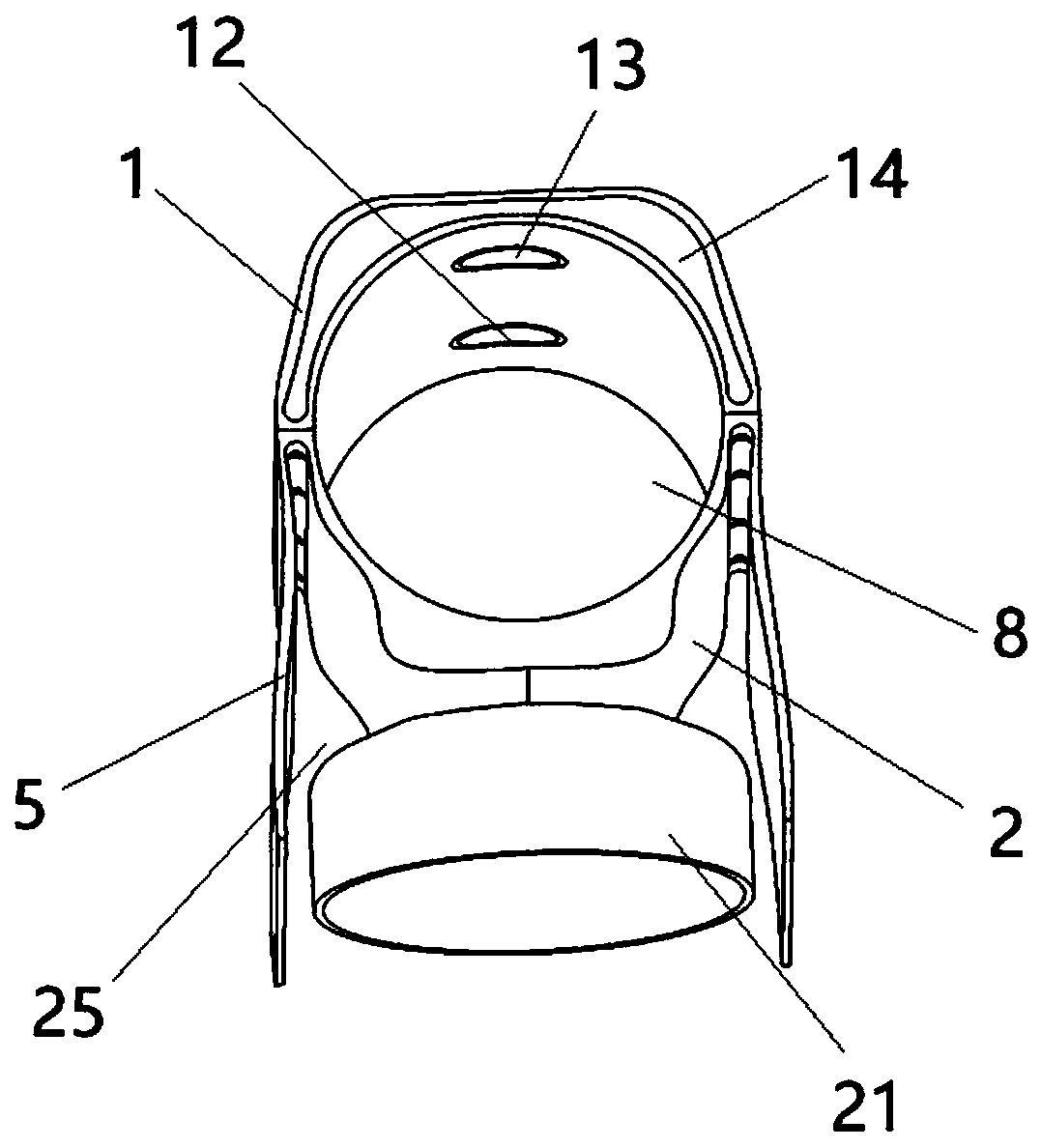

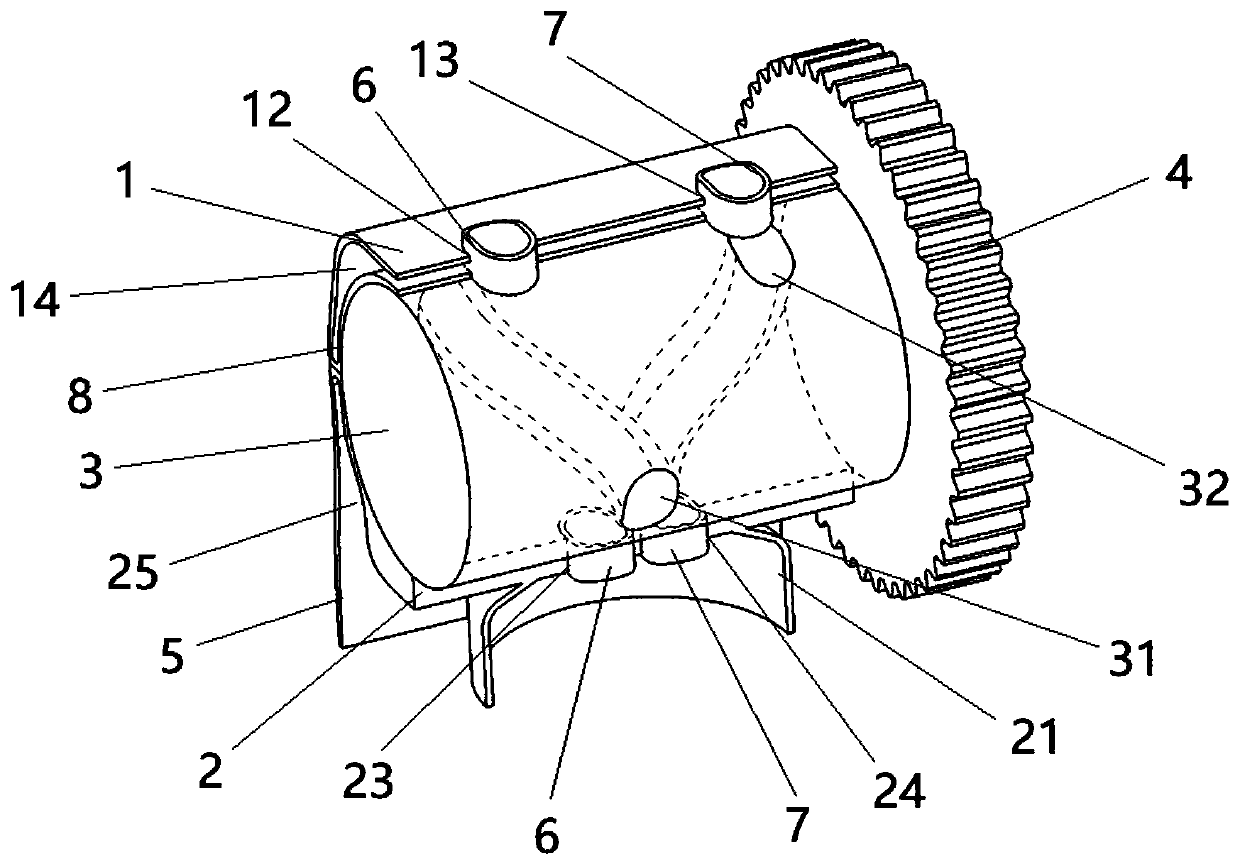

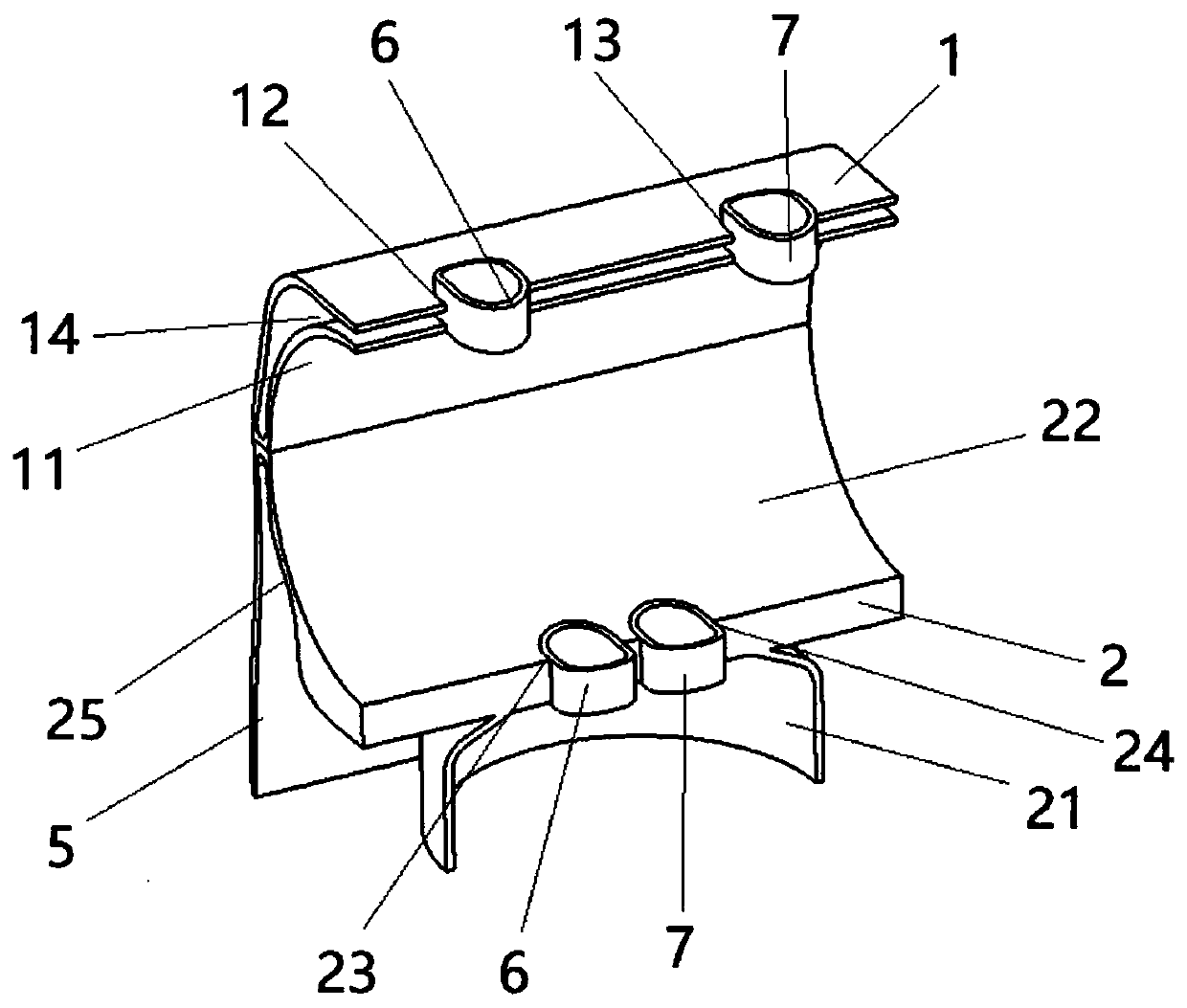

[0016] An internal combustion engine intake and exhaust rotary valve, such as figure 1 , figure 2 , image 3 As shown, it includes a valve cover 1, a valve body 2, a shaft 3, and a driving sprocket 4. The bottom of the valve body 2 is provided with a cylindrical protruding part 21, and the cylindrical protruding part 21 is used to communicate with the corresponding internal combustion engine cylinder block. , the top of the valve body 2 is provided with an arc-shaped first through groove 22, the bottom of the first through groove 22 is provided with a first air inlet 23 and a first exhaust hole 24, the first air inlet 23 and the second row The air holes 24 are all connected to the inner cavity of the cylindrical protruding part 21, and the two sides of the valve body 2 are respectively provided with baffles 5, the valve body 2 and the baffle 5 are integrally structured, and the baffle 5 is connected to the outer surface of the valve body 2, the valve body 2. The outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com