Small double-stage hammer-shaped pin roller oscillating tooth speed reducer

A movable tooth reducer and hammer-shaped technology, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of difficult to achieve large reduction ratio transmission, large axial structure, etc., to improve rigidity, Improve the bearing capacity, the effect of large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

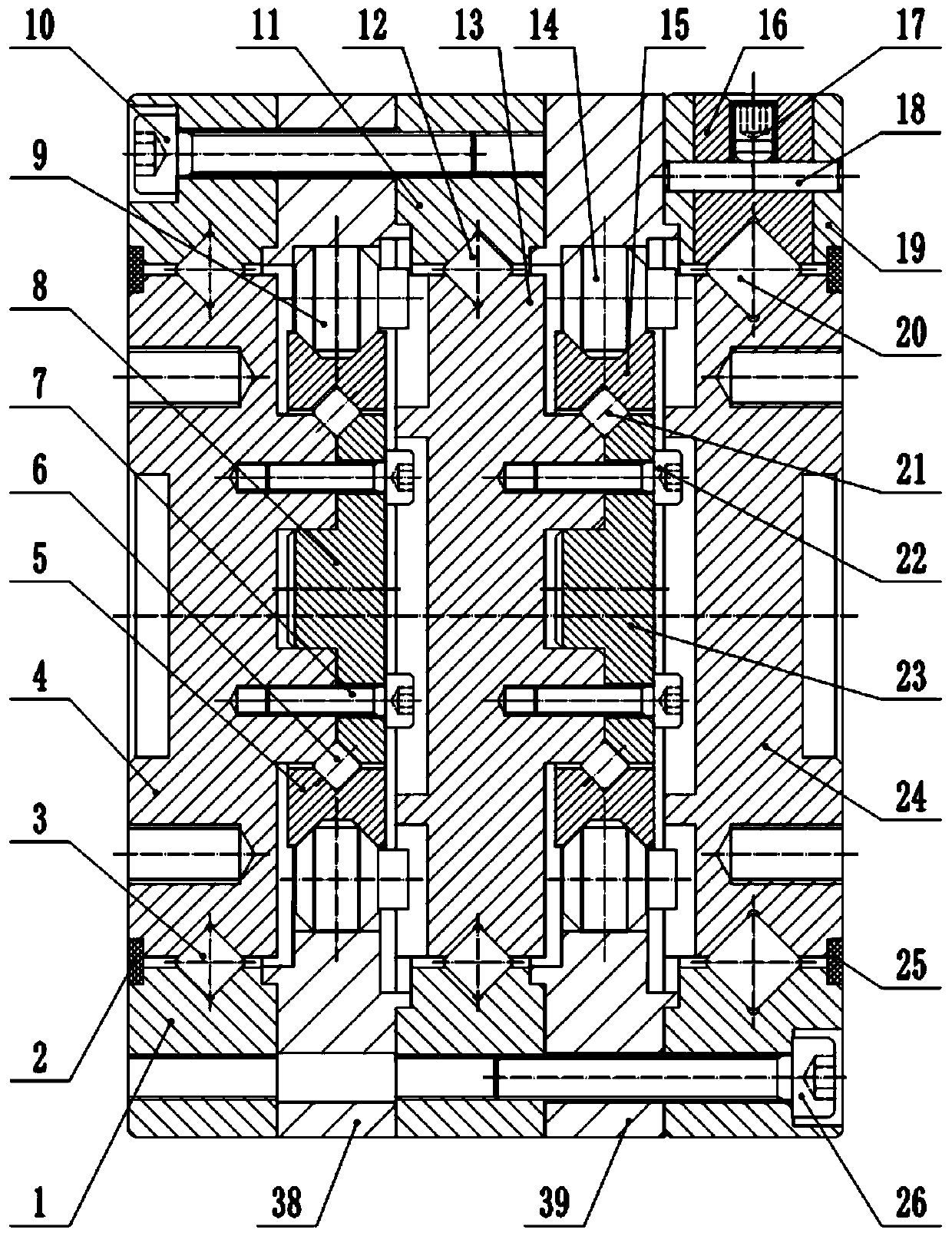

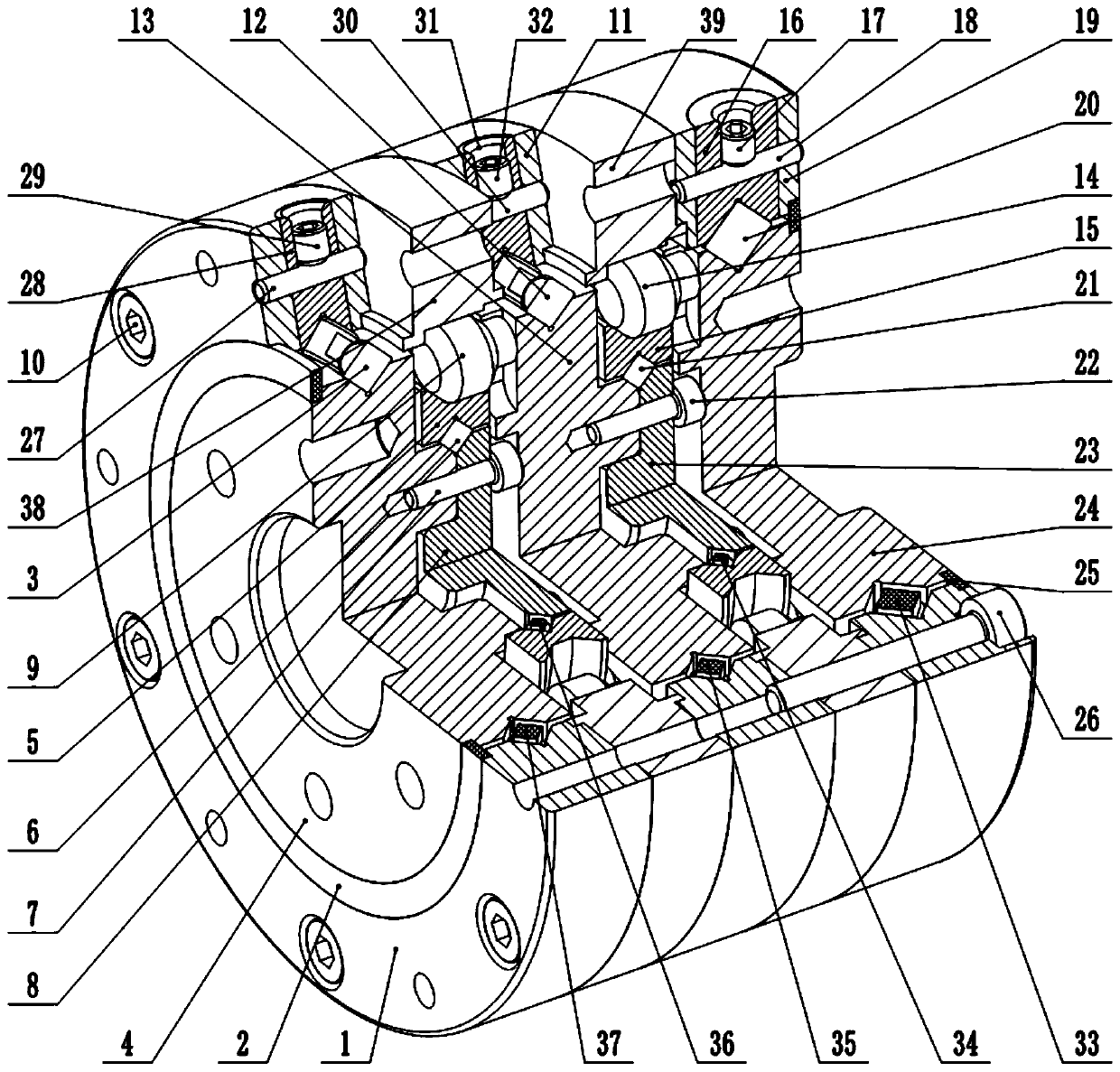

[0055] Such as figure 1 As shown, a small two-stage hammer roller movable tooth reducer is designed for a certain application occasion. As the preferred embodiment 1 of the present invention, its overall size is φ70mm in outer diameter and 48mm in length; the primary and secondary transmission The theoretical parameters are listed in Table 1.

[0056] Table 1 Example 1 Structural Theoretical Parameter Table

[0057]

[0058] Among them, the cone half-angles of the first cone surface 901 and the second cone surface 903 of the first-stage hammer roller movable tooth 9 and the second-stage hammer roller movable tooth 14 are both 45°, and the angle can be selected according to the actual stress situation. Certainly.

[0059] Such as Figure 1-8 As shown, a small double-stage hammer roller movable gear reducer includes a housing, in which an input shaft 4, a first-stage shock wave outer ring 5 hinged to each other and a first-stage shock wave are arranged in sequence along th...

Embodiment 2

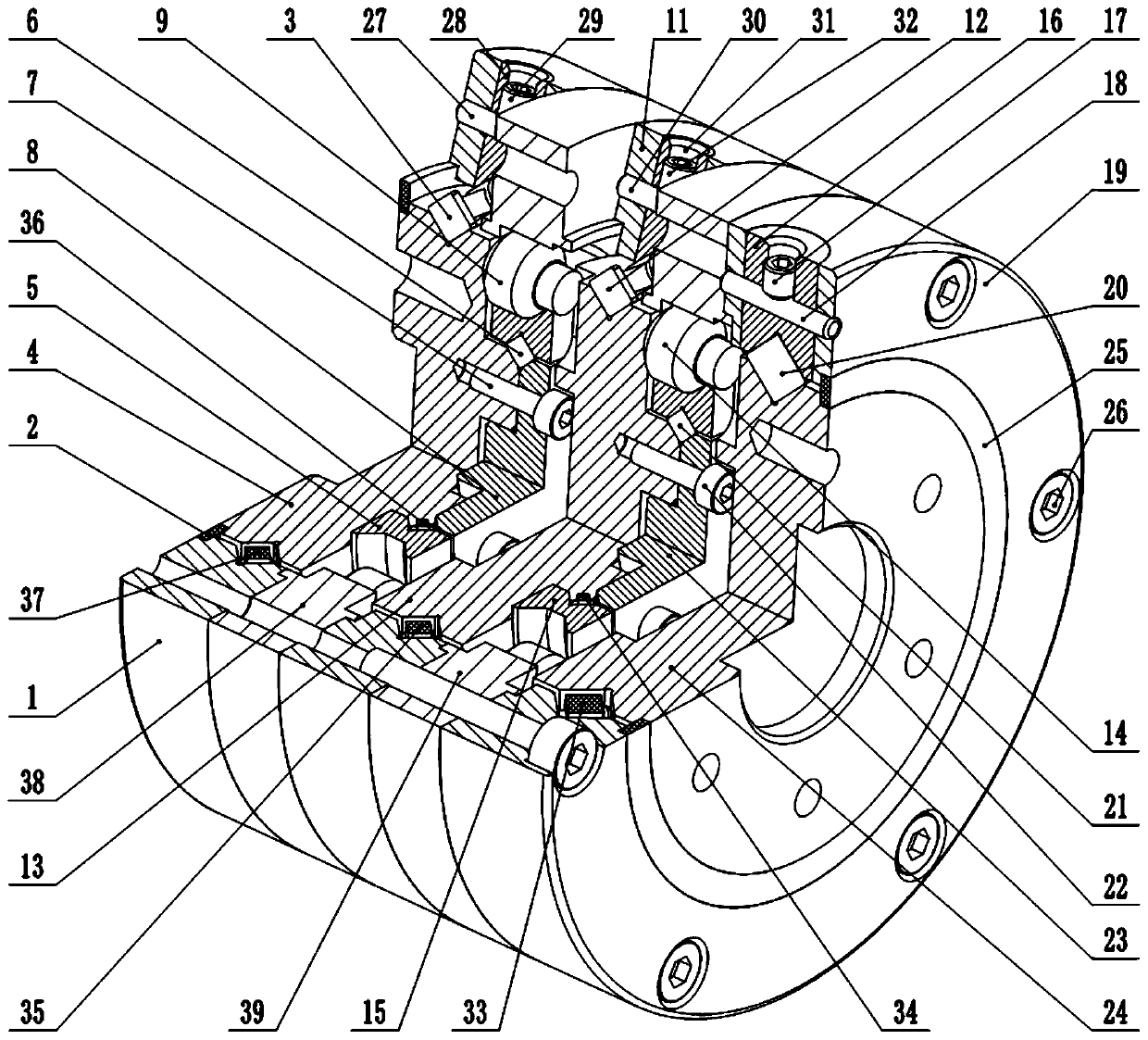

[0071] Such as Figure 9 As shown, a small double-stage hammer roller movable gear reducer is designed for a certain application, as the preferred embodiment 2 of the present invention, its overall size is, outer diameter φ70mm, length 48mm; this structure will be the embodiment The primary center wheel 38 and secondary center wheel 39 in 1 are split and recombined into the first housing 1, the second housing 11 and the third housing 19. The theoretical parameters of the primary and secondary transmissions are shown in Table 2.

[0072] Table 2 Embodiment 2 Structural Theoretical Parameter Table

[0073]

[0074]

[0075] Among them, the cone half-angles of the first cone surface 901 and the second cone surface 903 of the first-stage hammer roller movable tooth 9 and the second-stage hammer roller movable tooth 14 are both 60°, and the angle can be selected according to the actual stress situation. Certainly.

[0076] In particular, when the first-stage center wheel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com