LMS acquisition system and water hammer pressure parameter calibration method and processing method thereof

A collection system, water hammer technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problem of low signal accuracy, to ensure measurement accuracy, easy to intuitive interpretation, water hammer pressure signal measurement and calibration methods are convenient reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

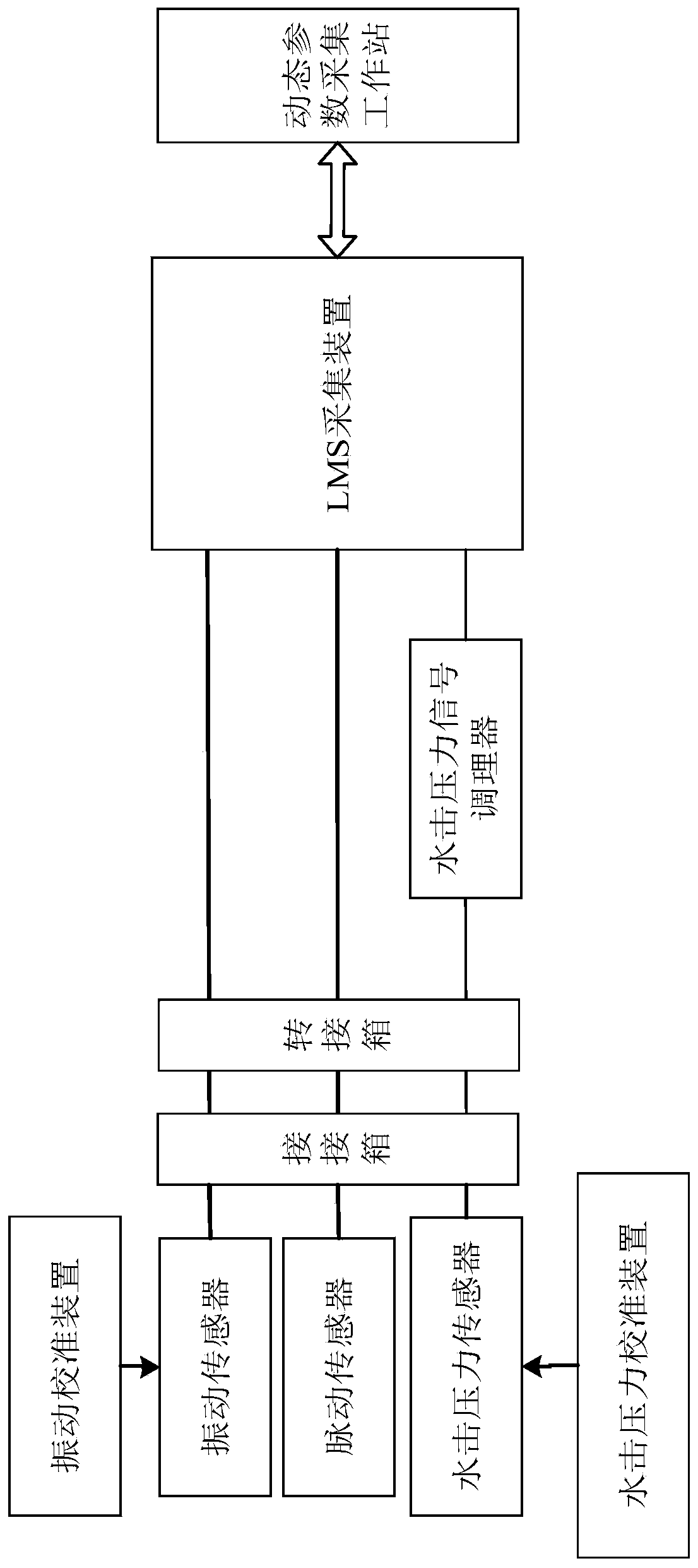

[0065] From figure 1 It can be seen that the LMS acquisition system of this embodiment introduces a water hammer pressure sensor and a water hammer pressure signal conditioner on the basis of the existing LMS acquisition system, mainly including a front-end sensor, an LMS acquisition device and a dynamic parameter acquisition workstation, wherein the front-end sensor Including a vibration sensor, a pulsation sensor, and a water shock pressure sensor. In other embodiments, the pulsation sensor and the vibration sensor can also be replaced by other types of sensors that can be applied to the LMS acquisition system. This embodiment also includes a vibration calibration device and a water shock pressure calibration device, both of which are used to realize online calibration of corresponding sensors.

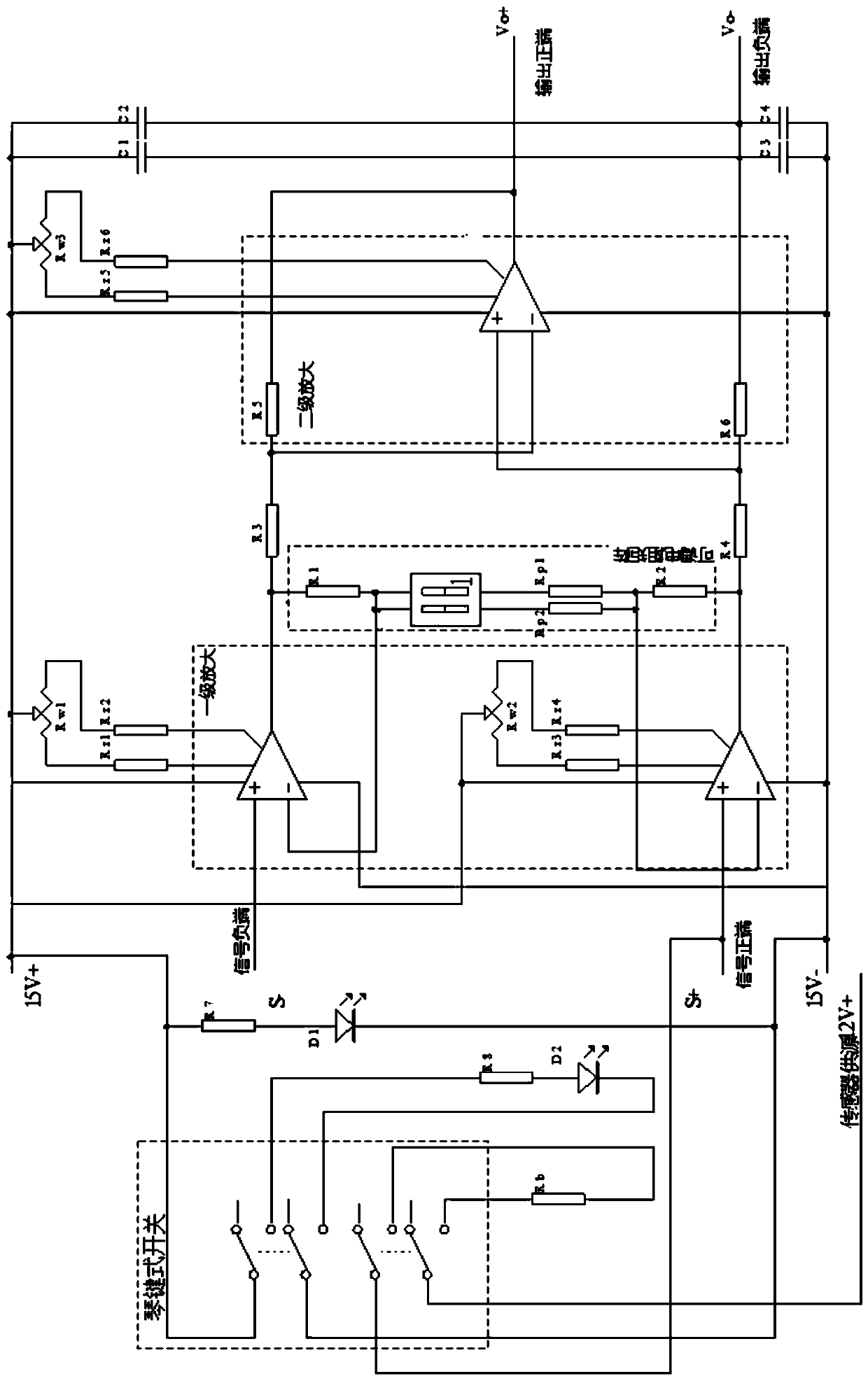

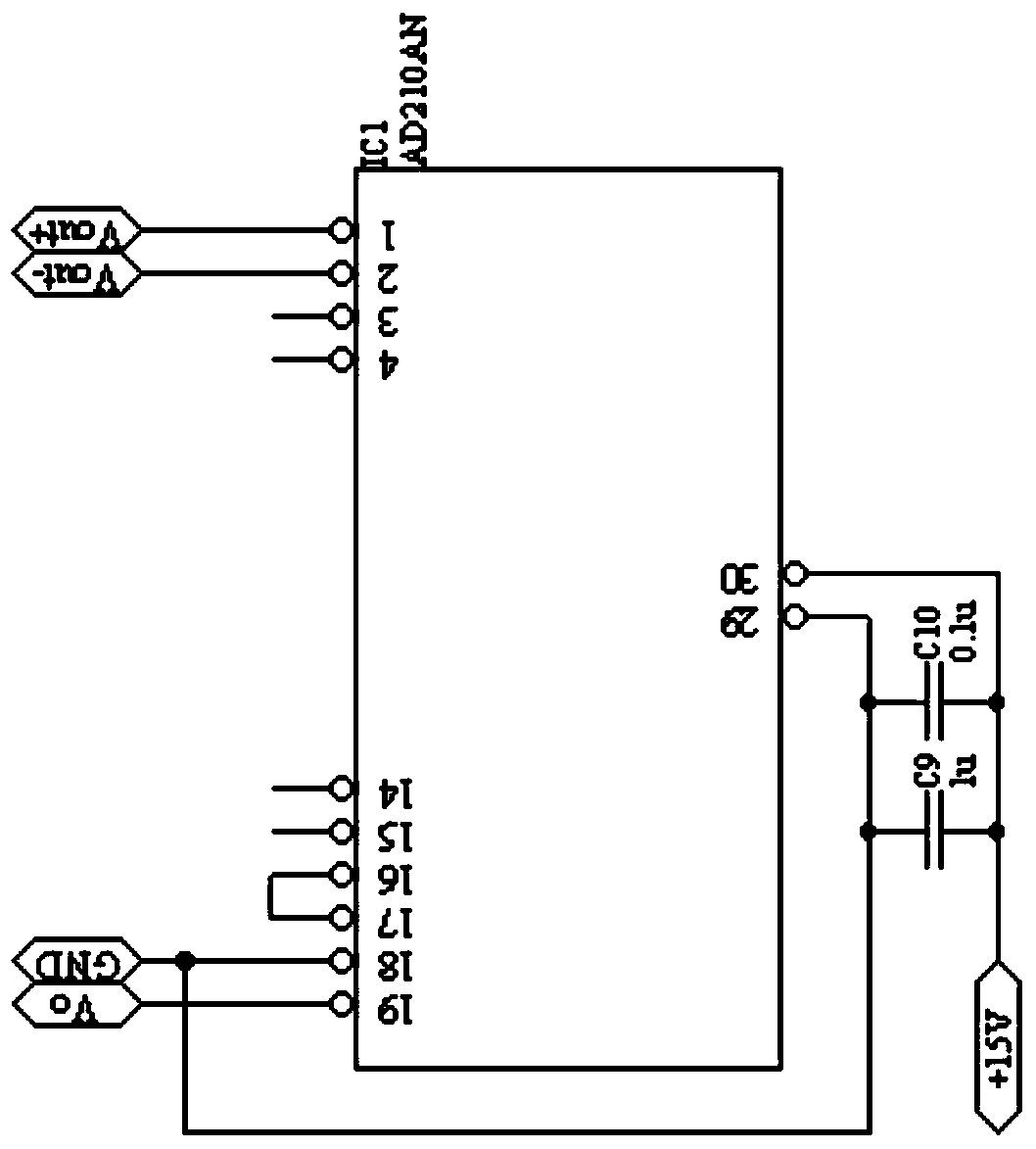

[0066] The water hammer pressure signal condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com