Grinding system energy consumption optimization method

A technology of grinding and grinding discs, which is applied to the parameter optimization of the grinding system, and optimizes the energy consumption of the mill through the mathematical model, which can solve the problems of missing the opportunity of process optimization and the inability to quickly capture the operating state of the process, so as to ensure the feasibility , the effect of improving the estimation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

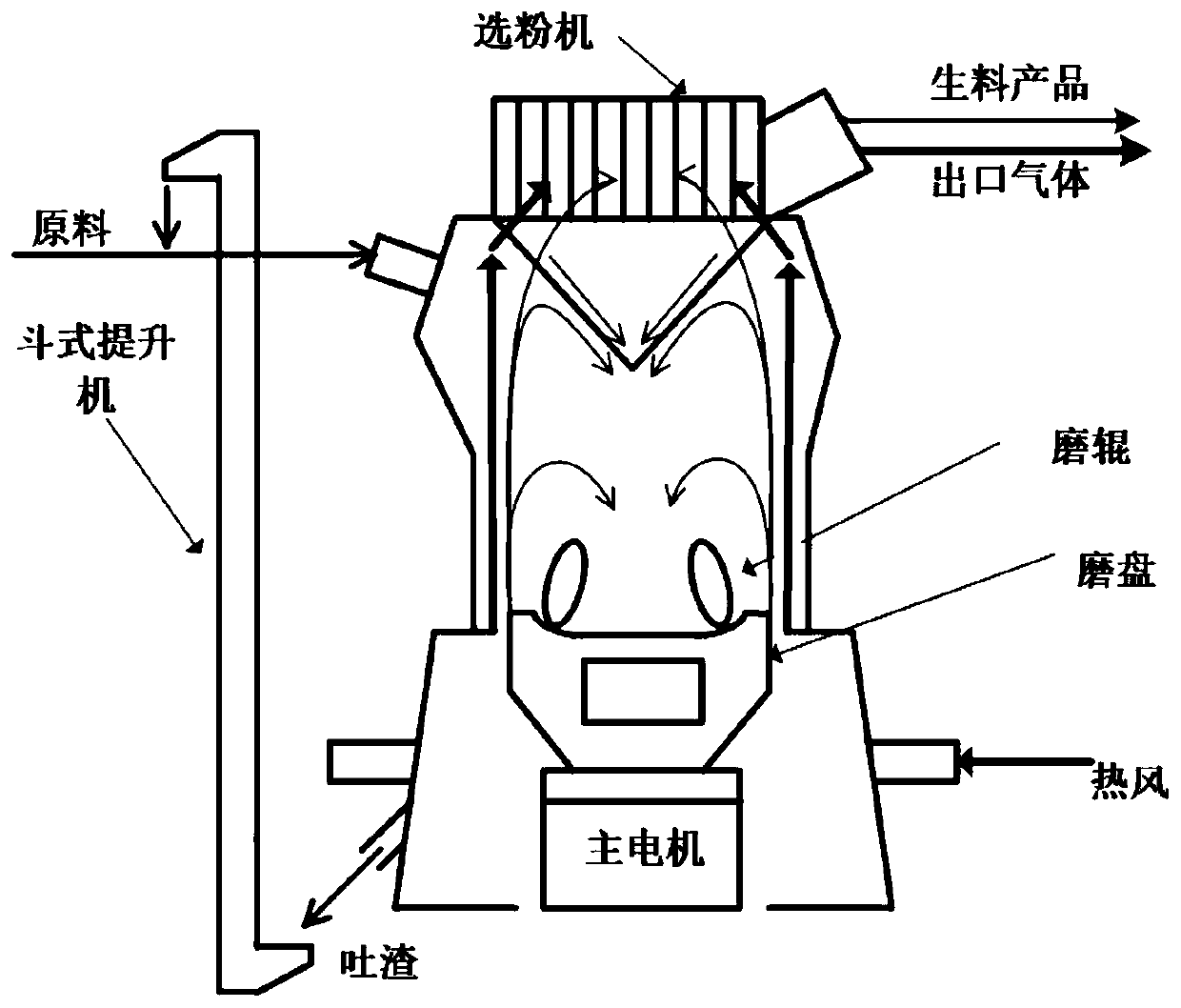

[0205] In step S01, the properties of the raw material are sampled multiple times to obtain an average value, which is used as the initial value of the parameters in the model, including the moisture content of the raw material and the hardness index of the raw material.

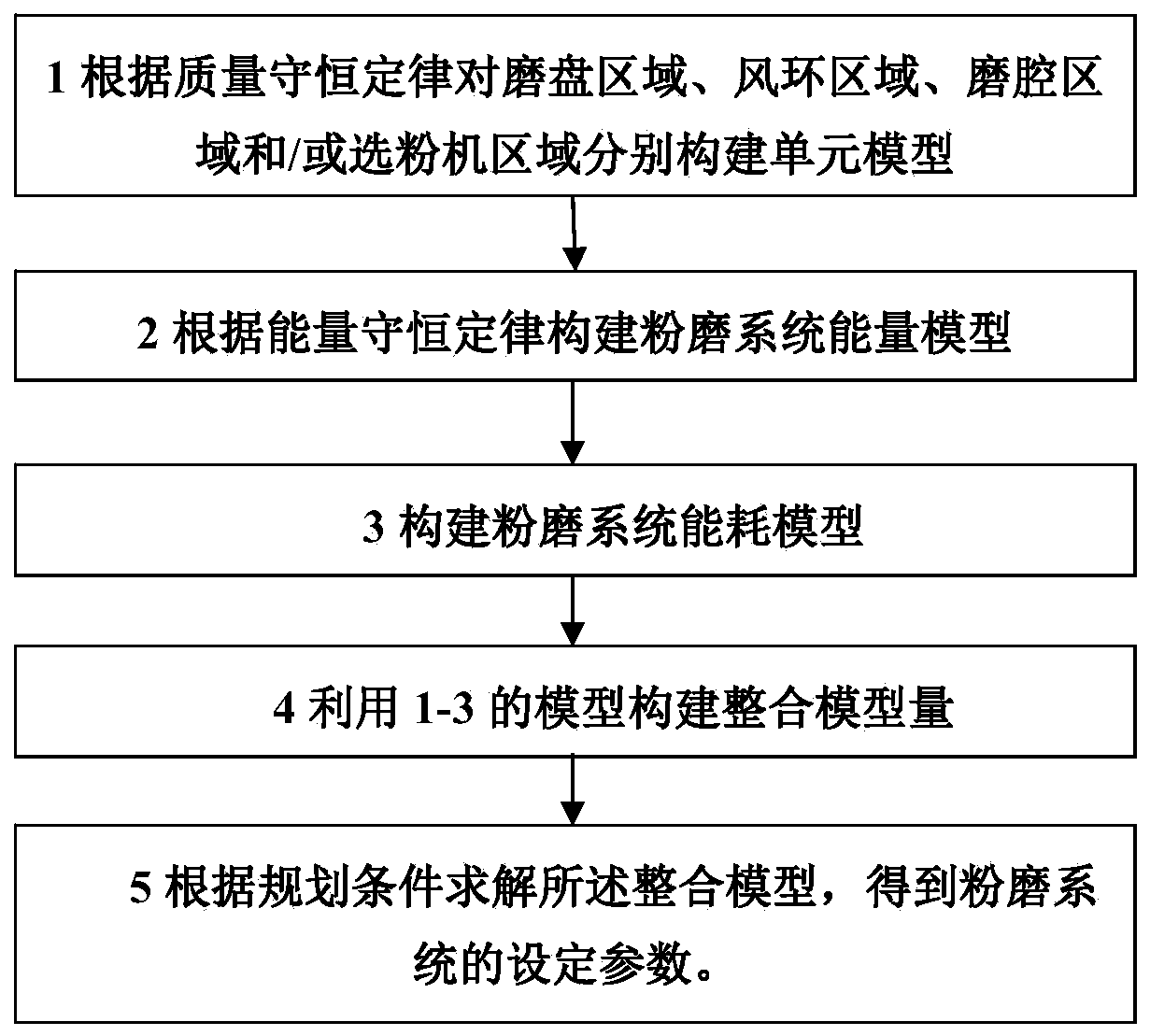

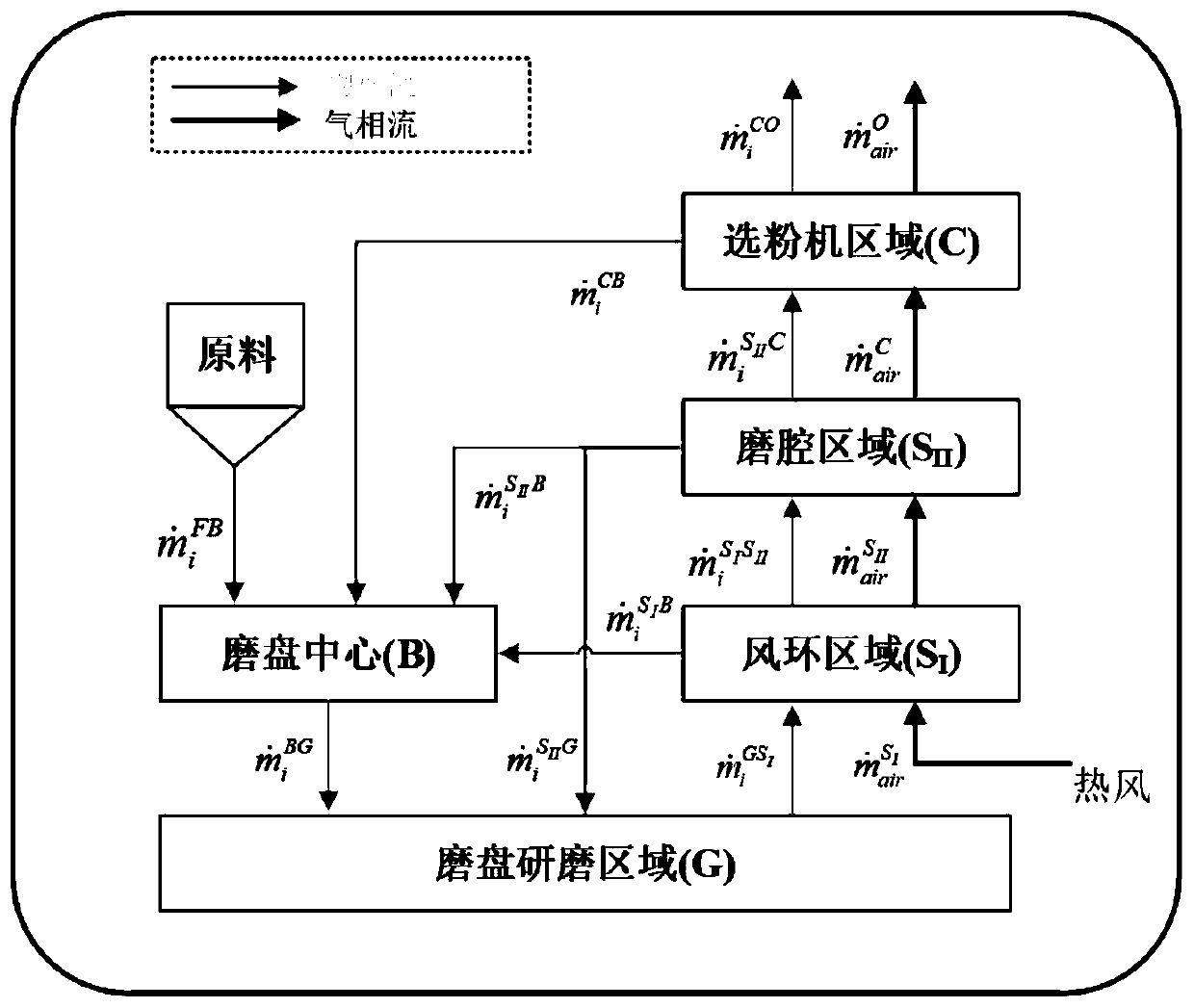

[0206] Step S02 establishes various steady-state models and optimization models through the equations shown in formulas (1-1)-(1-33), which also includes the correlation model between air volume and fan speed or baffle opening, gas viscosity coefficient and Establishment of empirical models such as the relationship between gas temperatures.

[0207] Step S03 estimates model parameters through historical data and empirical knowledge. The least squares method is used to estimate and solve the model parameters: the model parameters are used as decision variables, and the minimum square sum of the deviation between the actual process state and the model predicted state is used as the optimization goal to establi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap