Knitted fabric for business shirts

A technology for knitted fabrics and shirts, applied in knitting, shirts, weft knitting, etc., can solve the problems of increased elongation of knitted fabrics, thick knitted fabrics, and easy reduction of shape retention, and achieves excellent longitudinal shape retention, The effect of high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

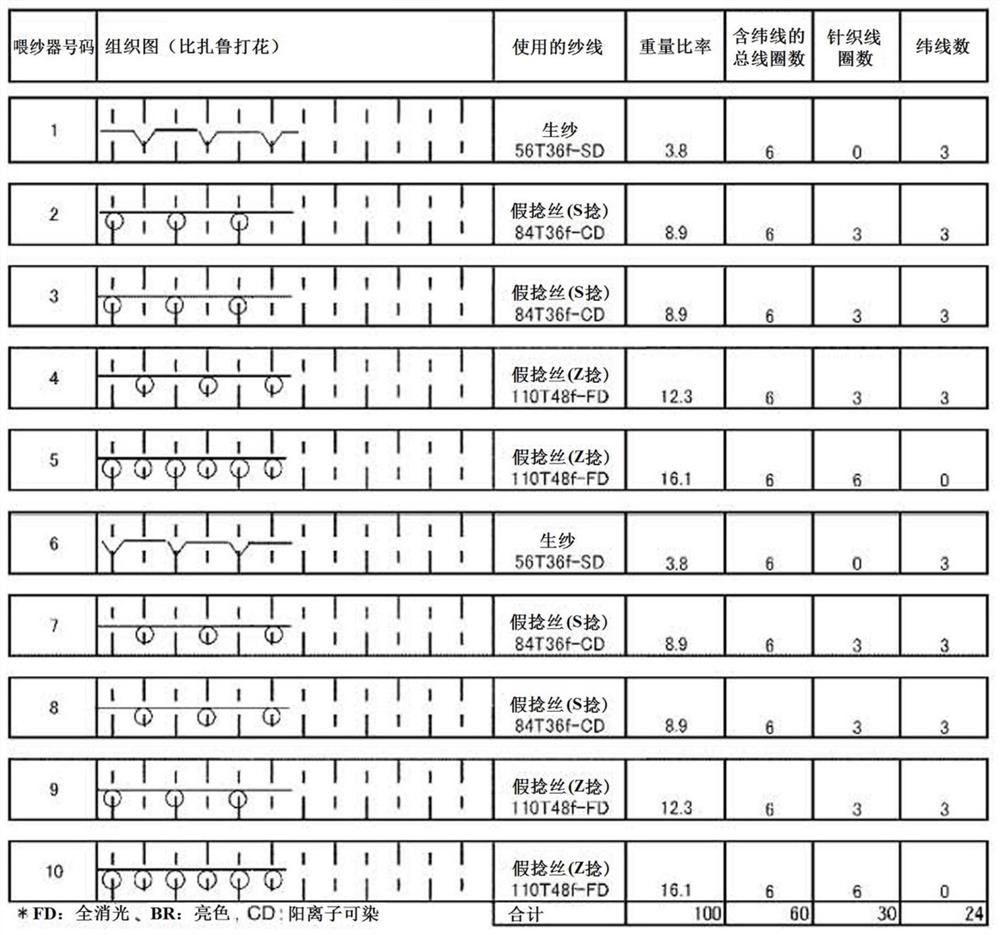

[0076] Using a 30-inch, 28-gauge single-sided circular knitting machine (VXC-3FA manufactured by Fukuhara Seiki Manufacturing Co., Ltd.), weaving is made of figure 1 The gray fabric of the 90-feed Bizaru pattern formed by the complete structures F1-F10 shown. At this time, polyethylene terephthalate of 110 dtex (T) and 48 filament (f) was used as a circular cross-section yarn kneaded with 1.5% by weight of titanium oxide fine particles at the yarn feeders F4, F5, F9, and F10. false twist yarn. Next, 84T36f false-twisted processed yarn, which is a circular cross-section yarn of high-pressure cationic dyeable polyester, was used at the yarn feeders F2, F3, F7, and F8. Then, raw yarn 56T36f, which is a semi-dull yarn with a flat cross section (warp-to-weft ratio 1:5) containing 0.4% by weight of titanium oxide fine particles, was used at the yarn feeders F1 and F6. The yarn length of each yarn feeder is 155mm / 100W for F2, F3, F4, F7, F8 and F9, the yarn length of F5 and F10 is ...

Embodiment 2

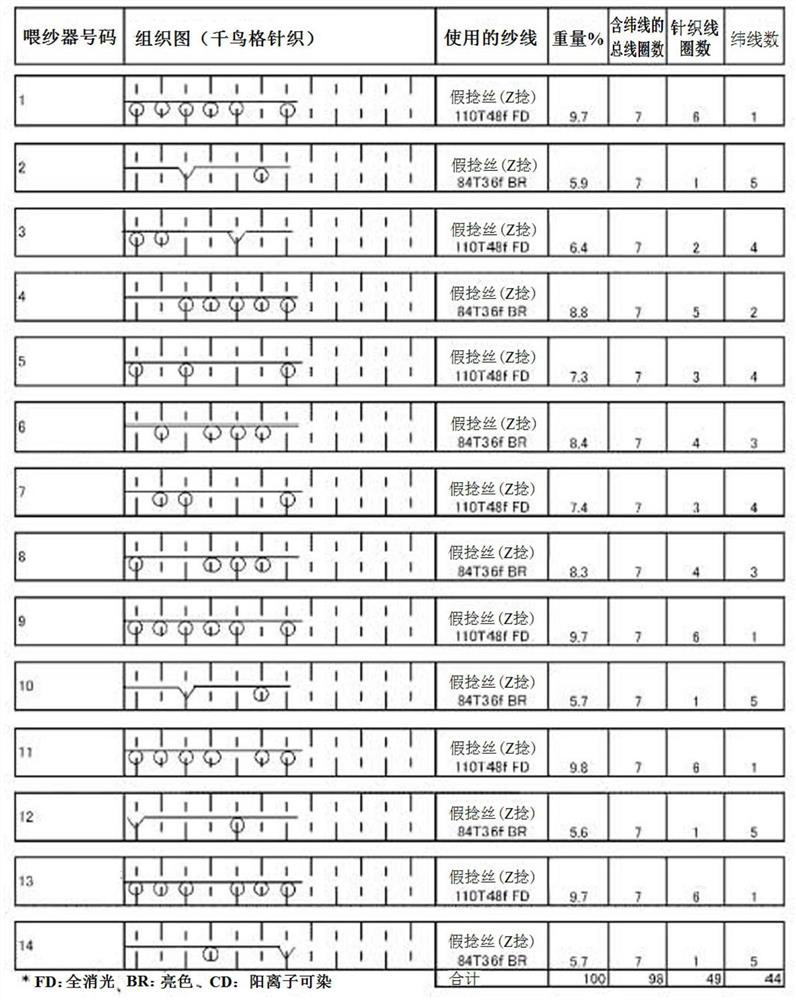

[0082] Using a 30-inch, 36-size semi-jacquard circular knitting machine (JSIII manufactured by Fukuhara Seiki Manufacturing Co., Ltd.), weaving is made of figure 2 Gray cloth of a houndstooth pattern formed by the complete weaves F1 to F14 shown. At this time, 110T, 48f polyethylene terephthalate, which is a circular cross-section yarn kneaded with 1.5% by weight of titanium oxide particles, was used at the yarn feeders F1, F3, F5, F7, F9, F11, and F13. False twist yarn (Z twist). Next, 84T, 36f polyethylene terephthalate dummy which is a circular cross-section yarn mixed with 0.1% by weight of titanium oxide particles is used at the yarn feeders F2, F4, F6, F8, F10, F12, and F14. Twisted yarn (Z twist). The average yarn length of the complete weaves constituting F1 to 14 was 135 mm / 100W.

[0083] Dyeing processing was performed in the same manner as in Example 1 except that the finished gray cloth was finished with off-white color without using a dye. The density of the ...

Embodiment 3

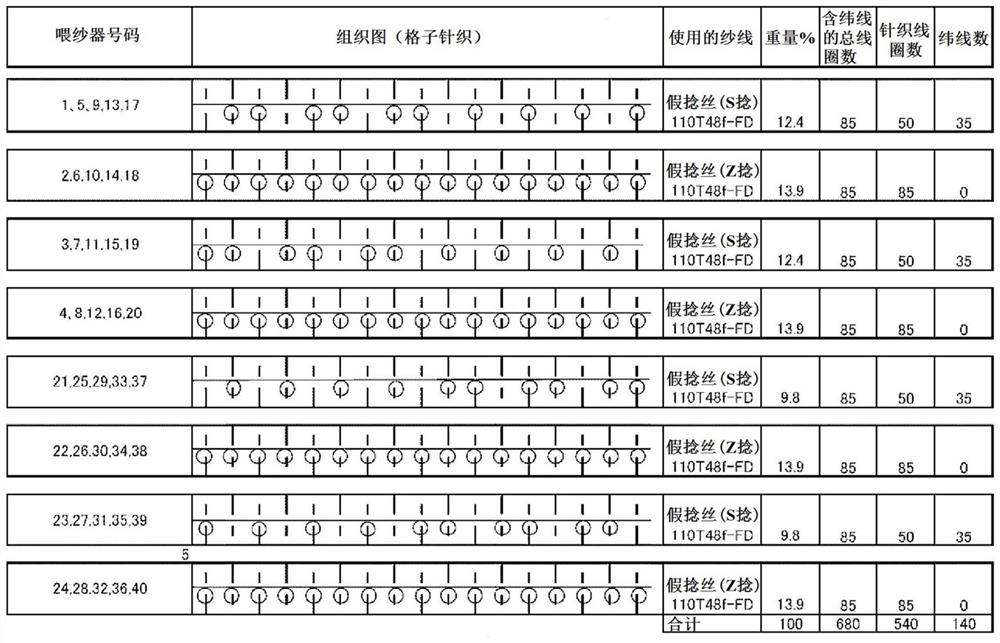

[0085] Use the loom identical with embodiment 2, weave by image 3 Check pattern fabrics formed by the complete structures F1 to F40 shown. The yarn used was 110T, 48f polyethylene terephthalate false twist yarn which is a circular cross-section yarn kneaded with 1.5% by weight of titanium oxide fine particles. At this time, S-twisted yarn is used in odd-numbered yarn feeders, and Z-twisted false-twisted yarn is used in even-numbered yarn feeders. The average yarn length of the odd number F of F1 to F19 is 135 mm / 100W, and the average yarn length of the odd number F of F21 to F39 is 110 mm / 100W. The average yarn length of even-numbered F from F2 to F40 is 165mm / 100W. The average yarn length of the whole yarn constituting the complete weave is 144mm / 100W.

[0086] The finished fabric was dyed in the same manner as in Example 1 to obtain a finished knitted fabric with a density of 76 courses / 2.54 cm and 61 wales / 2.54 cm. The detailed composition and evaluation results of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com