Timepiece part, and timepiece

A technology for clocks and components, applied in clocks, applications, watch straps, etc., can solve the problems of damage resistance, friction resistance, high-end appearance, high price of precious metal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0054] First, the timepiece component of the first embodiment will be described.

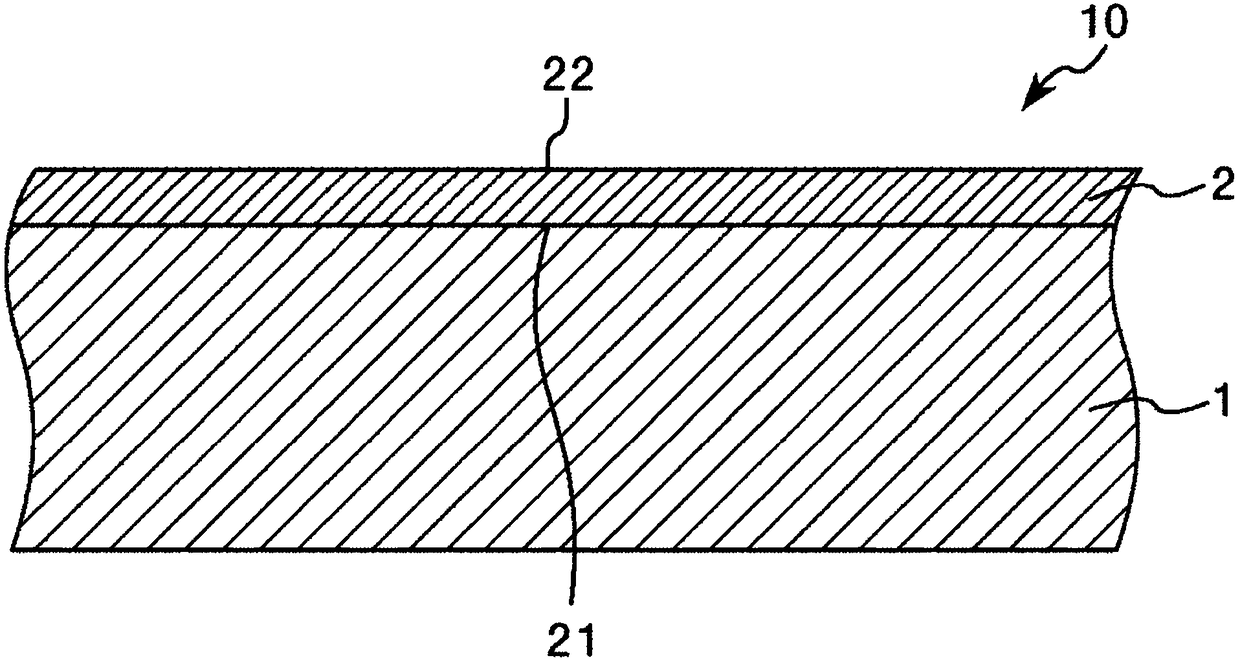

[0055] figure 1 It is a sectional view schematically showing the first embodiment of the timepiece component of the present invention. Below, to figure 1 The upper side of the diagram will be described centering on the case where the observer's viewpoint side is set as the upper side (about Figure 2 to Figure 10 , and the same).

[0056] The timepiece component 10 of the present embodiment includes a base material 1 and a first film 2 containing Co as a main component and containing Cr, The material composition contains Mo at a content rate of 5% by mass or more and 7% by mass or less.

[0057] Furthermore, in the surface 22 of the first film 2 (the second surface 22 on the opposite side to the first surface 21 facing the substrate 1), when the measurement by the atomic force microscope is carried out, the surface 22 is flat. The surface area increase rate is 0% or more and 1.2% or less on...

no. 2 approach

[0133] Next, a timepiece component of a second embodiment will be described.

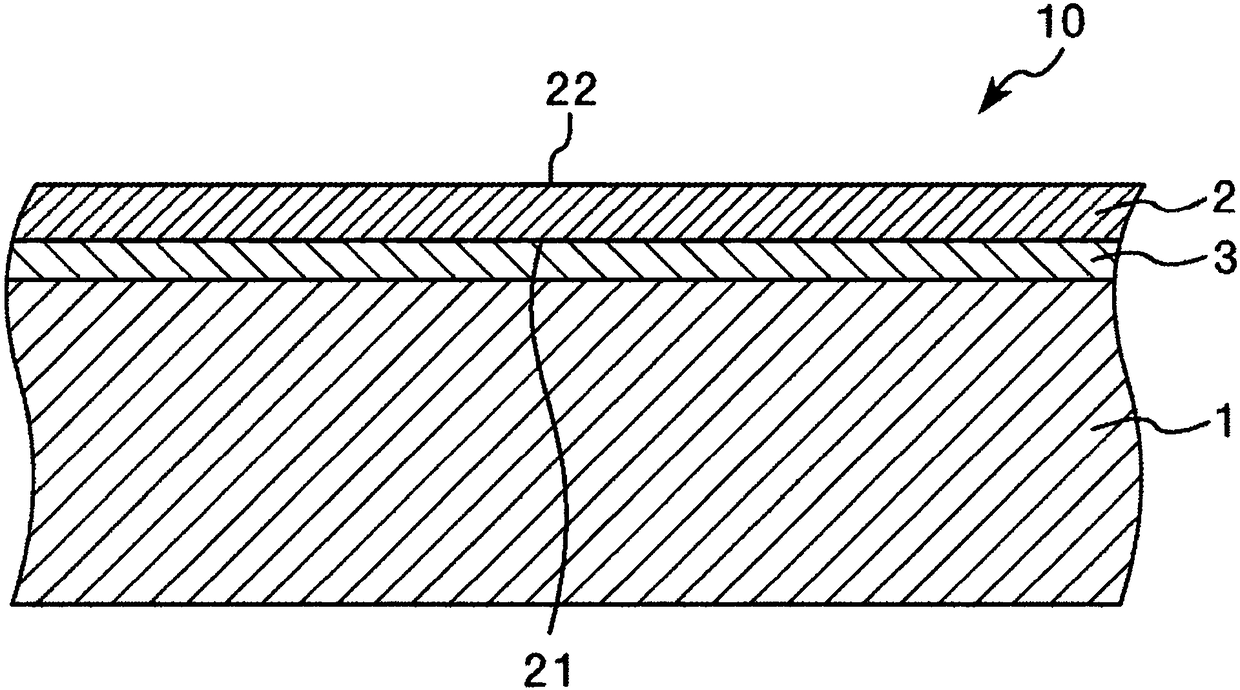

[0134] figure 2 It is a cross-sectional view schematically showing a second embodiment of the timepiece component of the present invention. In the following description, differences from the above-described embodiments will be mainly described, and descriptions of the same matters will be omitted.

[0135] In the timepiece component 10 of the present embodiment, a base layer (first base layer) 3 and a first film 2 are sequentially laminated on the surface of the base material 1. The base layer (first base layer) 3 consists of The first film 2 is composed of a material containing Ti, and the first film 2 contains Co as a main component, and contains Cr at a content rate of 26% by mass to 30% by mass, and a content rate of 5% by mass to 7% by mass. Composition of a material containing Mo. In other words, in the timepiece component 10 of the present embodiment, the base layer 3 made of a material c...

no. 3 approach

[0158] Next, a timepiece component according to a third embodiment will be described.

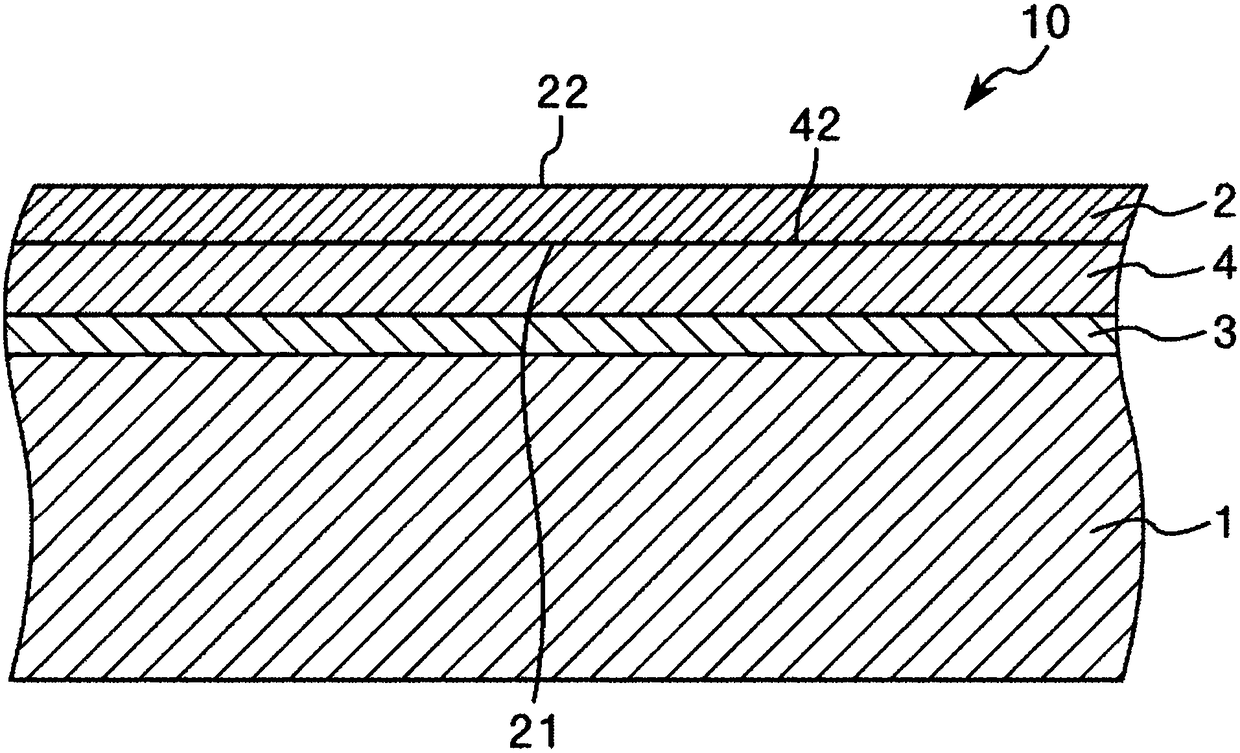

[0159] image 3 It is a cross-sectional view schematically showing a third embodiment of the timepiece component of the present invention. In the following description, differences from the above-described embodiments will be mainly described, and descriptions of the same matters will be omitted.

[0160] In the timepiece component 10 of the present embodiment, the base layer (first base layer) 3, the second coating film 4, and the first coating film 2 are sequentially stacked on the surface of the base material 1. The base layer (first base layer) The bottom layer) 3 is composed of a material containing Ti, the second film 4 is composed of a material containing at least one of TiC and TiCN, and the first film 2 is composed of Co as a main component and the mass percentage is 26% or more and the mass percentage The material configuration includes Cr at a content rate of 30% or less and Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com