Zirconia sintered body

A technology of zirconia and sintered bodies, applied in dental prosthesis, chemical instruments and methods, dentistry, etc., can solve the problems of long processing time and low aesthetics of preforms, and achieve shortened processing time, excellent aesthetics, and reduced The effect of the amount of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1

[0135] The zirconia calcined body and the sintered body of each example and comparative example were produced according to the following procedure.

[0136] The method for producing the raw material powder will be described. First, a mixture was prepared using monoclinic zirconia powder and yttrium oxide powder (the yttrium oxide content rate was 4 mol%). Next, this mixture was added to water to prepare a slurry, which was wet pulverized and mixed with a ball mill until the average particle diameter became 0.13 μm or less. The pulverized slurry was dried by spray drying, and the obtained powder was calcined at 1000° C. for 2 hours to prepare a powder (primary powder). Through the raw material in the spray drying machine, the powder is processed until the content of the specification is achieved.

[0137] The obtained primary powder was divided into four as the first to fourth powders, and a pigment was added to each powder so as to have the content shown in Table 1 (the cont...

Embodiment 3

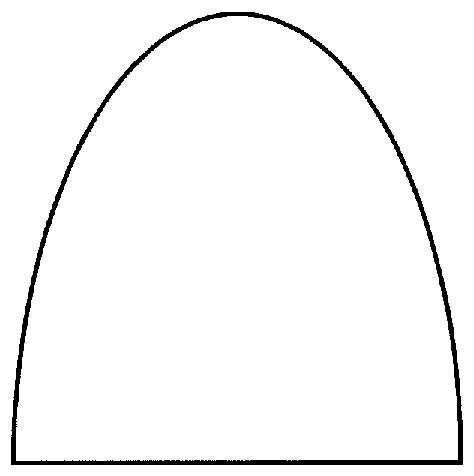

[0143] Set the shape of the base to Figure 1D A zirconia calcined body and a sintered body were fabricated in the same manner as in Example 1 except for the shape obtained by combining the rectangle and the semicircle shown.

[0144] [Confirmation of deformation of zirconia sintered body]

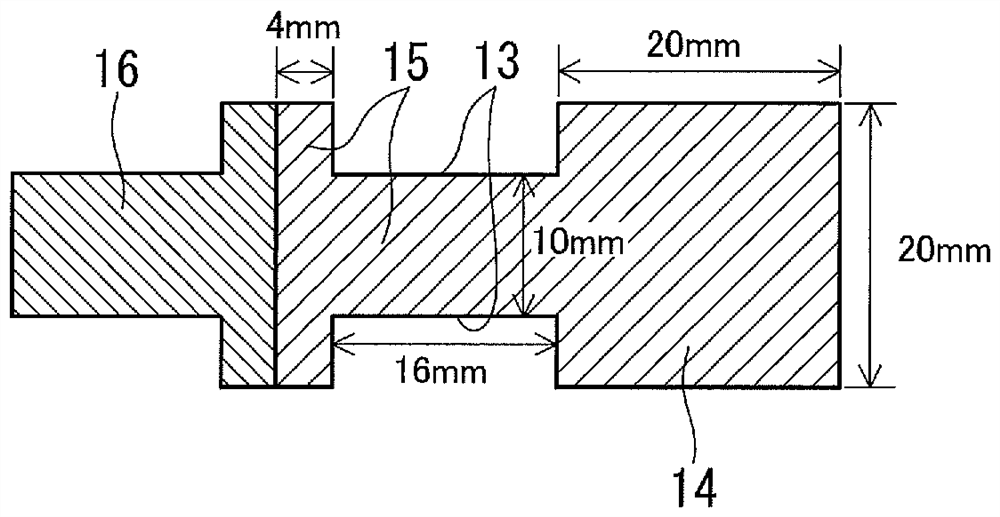

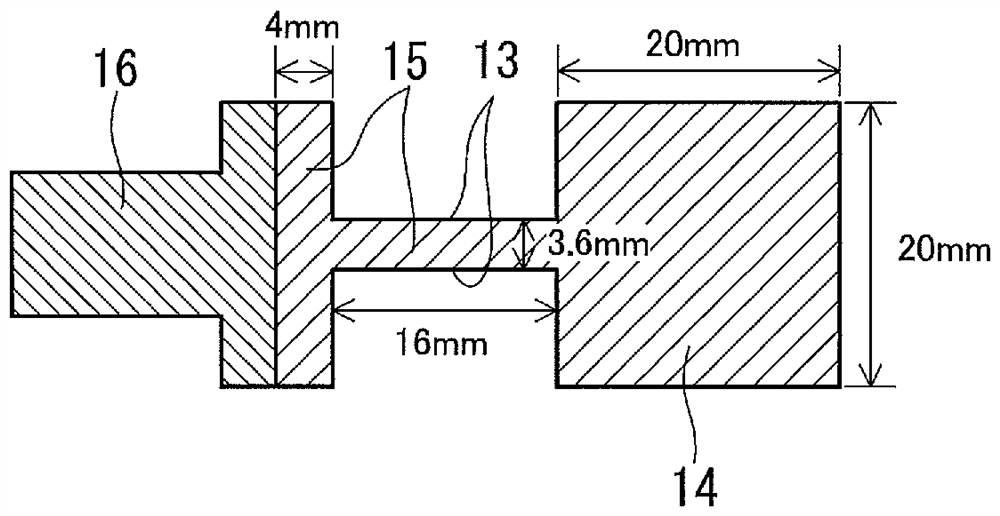

[0145] The zirconia sintered body produced by the aforementioned method was processed into Figure 3A , Figure 3B , Figure 4A , Figure 4B , Figure 5A and Figure 5B The shape shown (however, the dimensions described in these drawings are the values after sintering). The processed zirconia calcined body was calcined at 1550° C. for 120 minutes to produce a zirconia sintered body. The zirconia sintered bodies of Examples 1-2 are shown in Figure 3A , Figure 3B , Figure 4A ,and Figure 4B , the bottom surface diagram of the zirconia sintered body of Example 3 is shown in Figure 1D , the zirconia sintered body of Comparative Example 1 is shown in Figure 5A and Figure 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com