Dedusting wind pressure balancing device

A wind pressure and balanced technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of corrosion of the main pipe in front of the dust collector of the ground dust removal station, the influence of the dust removal effect on the dust removal station, and the failure to work normally, etc., to achieve Beautiful appearance, tight closing and responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

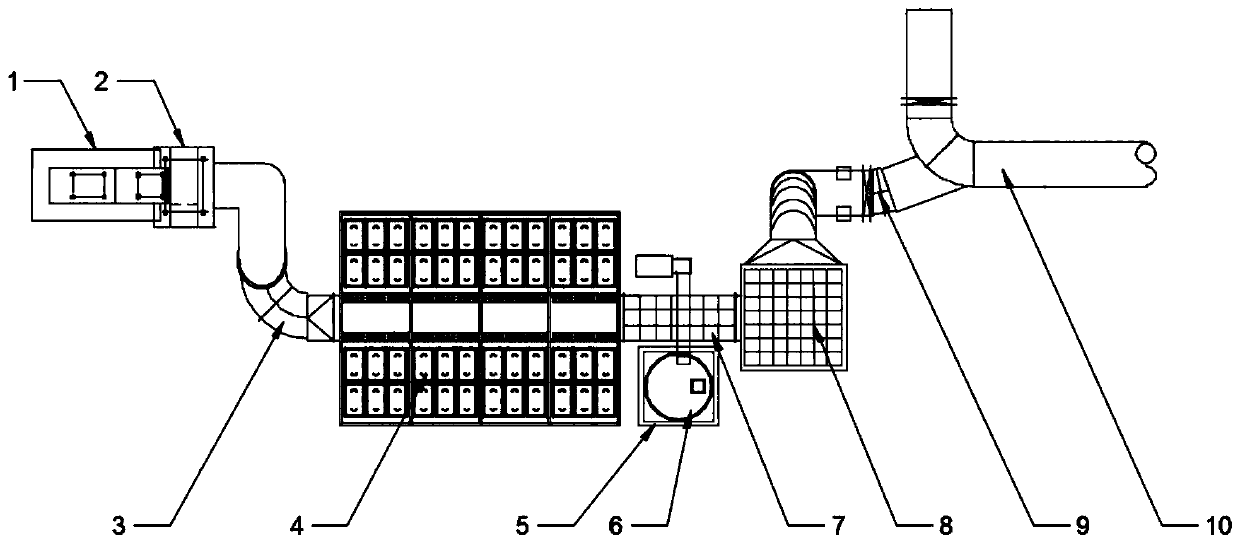

[0020] When the present invention is implemented in practice, a dust removal balance wind pressure device includes a fan 1, a chimney 2 that is connected to the fan port specification and size on one side of the fan 1, and the chimney 2 is connected to the pipe 3 through the outlet. A bag dust collector 4 is connected, and the side of the bag dust collector 4 opposite to the outlet connecting pipe 3 is connected to a fire arresting box cooler 8 through a connecting pipe 7, and one end of the fire arresting box cooler 8 is passed through a pipe And the elbow structure 9 is connected to the dust removal dry pipe 10 of the coke oven equipment;

[0021] A bucket elevator 5 is installed at one end of the connecting pipe 7, and an ash storage bin 6 is arranged in the bucket elevator 5;

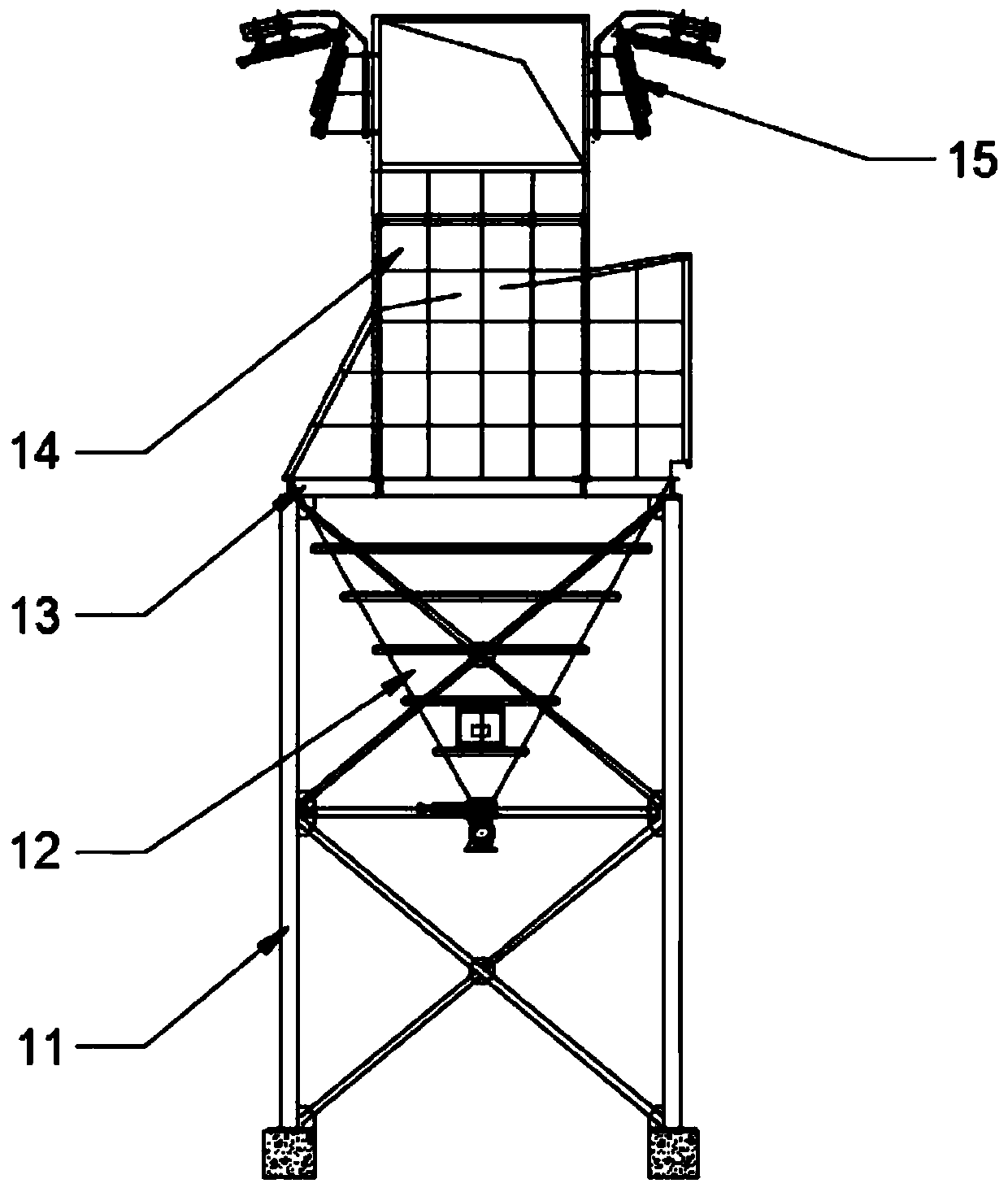

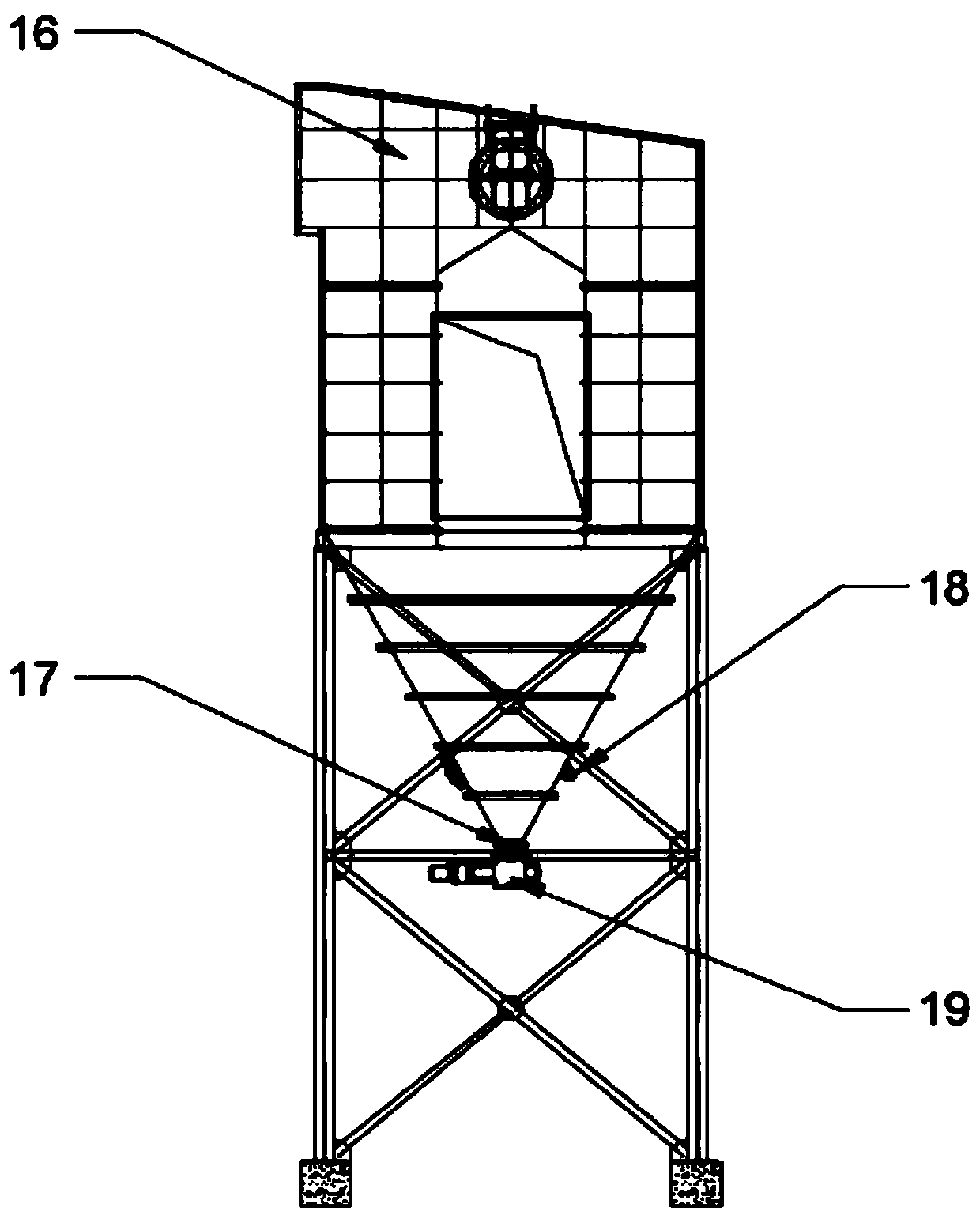

[0022] The fire retardant box cooler 8 includes a bracket 11, a ring beam 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com