Double-fluid fog gun and application thereof

A two-fluid, fog cannon technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficult to manually start the dust suppression fog cannon, difficult to effectively reduce dust, high water consumption, etc., to achieve accurate Automatically track the effect of spray dust reduction and accurate capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

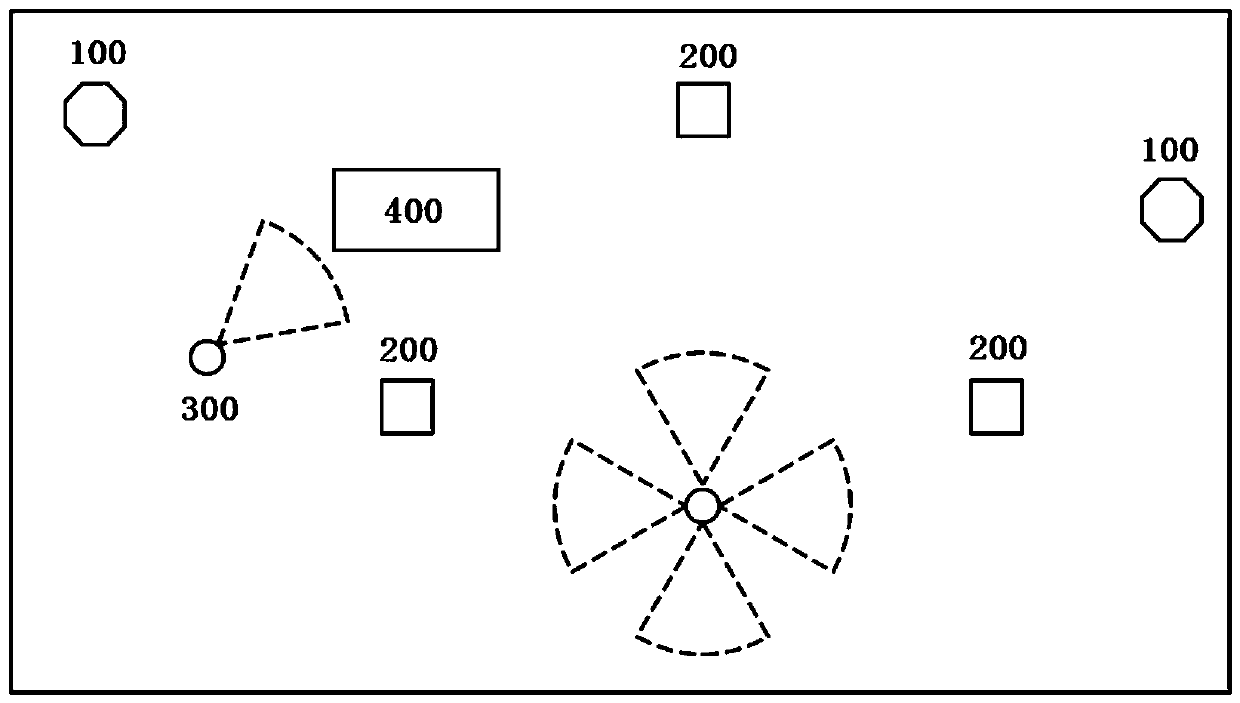

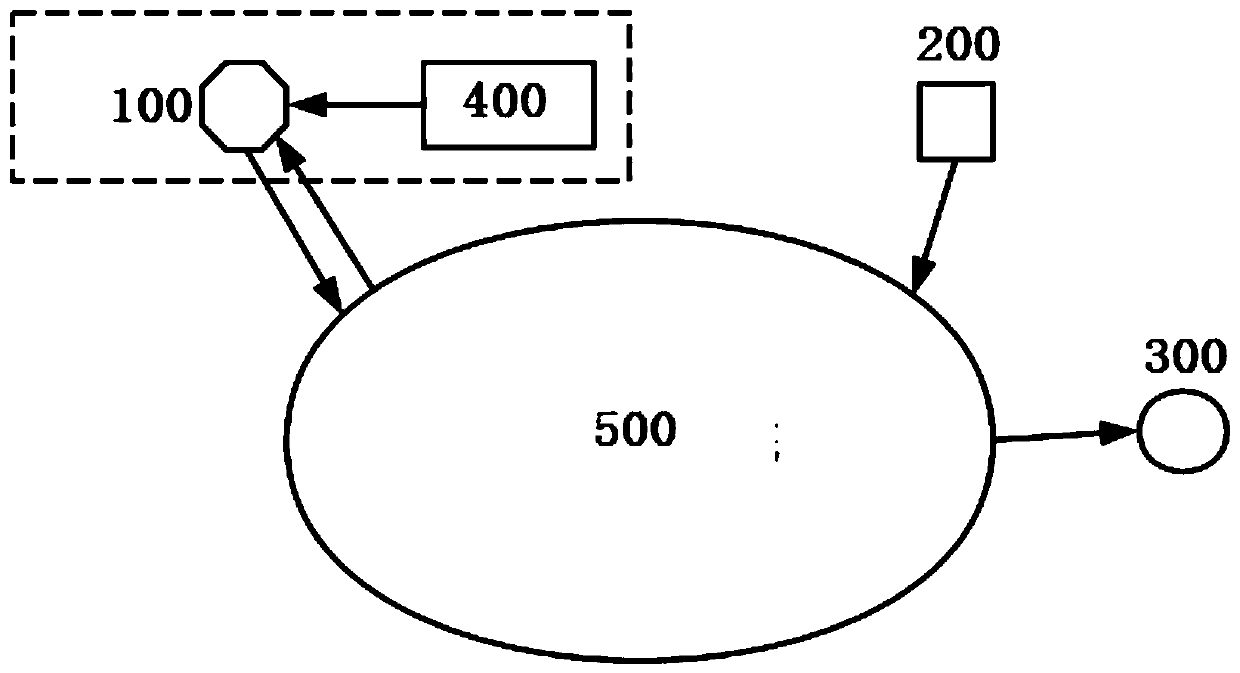

[0096]The dual-fluid fog cannon of the present invention is installed in the stockpile shed in the iron and steel plant. There are material transport vehicles driving and loading and unloading materials in the stockpile shed. Since the production activities will generate dust, it is necessary to suppress the unorganized dust. During specific installation, the material shed is divided into several areas, and an eagle-eye capture module 100 is arranged in each area. The eagle-eye capture module 100 is generally arranged at a higher place, such as the top of a steel column, a steel beam, and the like. It is ensured that all eagle-eye identification modules 100 can cover the entire material shed, and that the coverage area of each eagle-eye identification module 100 does not overlap as much as possible, that is, no omission or repetition.

[0097] The eagle-eye capture module 100 takes real-time pictures of the material shed, can quickly and accurately capture polluting vehicles,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com