Oil spraying jig for strip-shaped materials

A fixture and material technology, which is applied in spray booths, spray devices, liquid spray devices, etc., can solve the problems of high cost investment and high fuel injection requirements, and achieve the goal of reducing cost investment, reducing facility investment, and ensuring the fuel injection environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

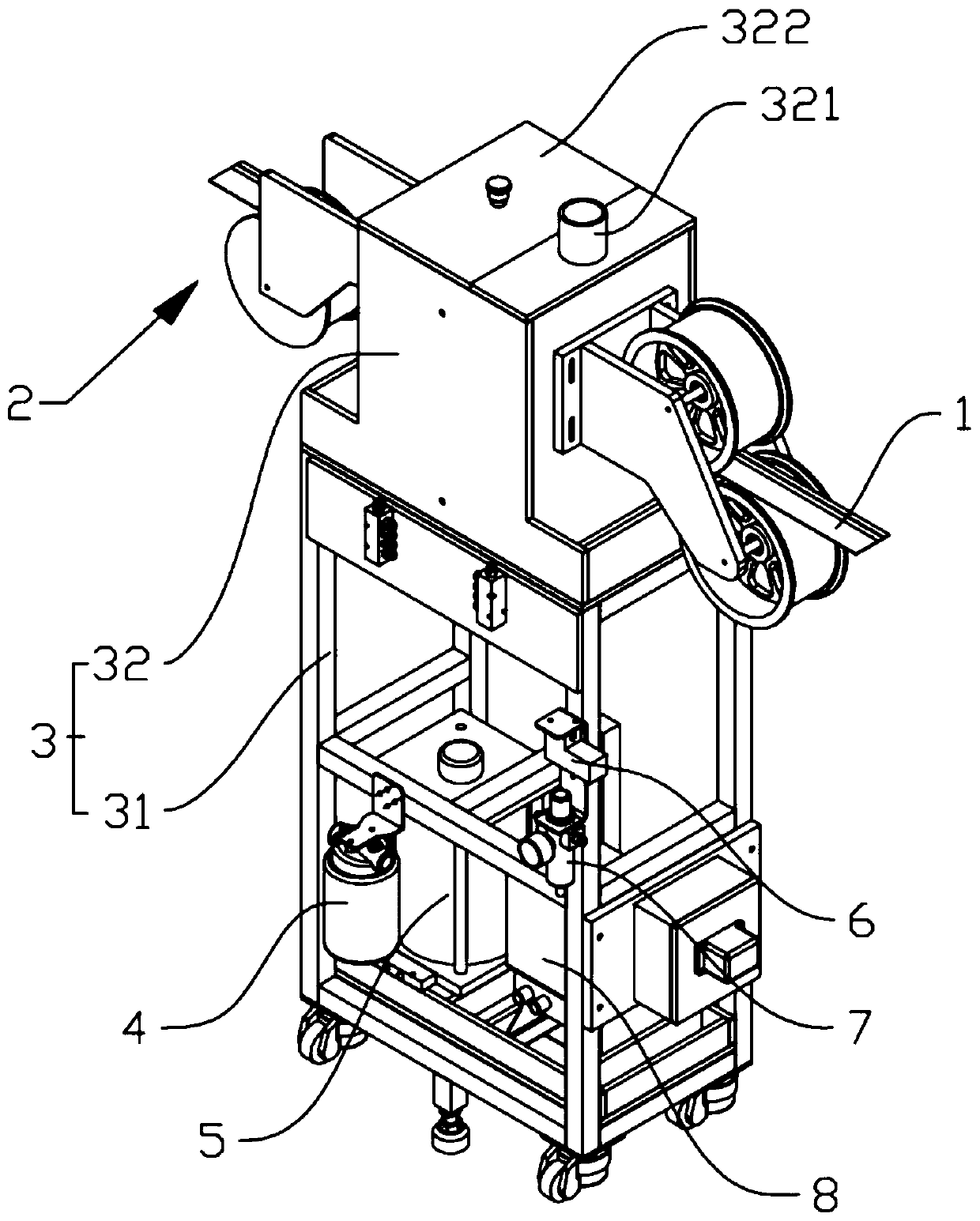

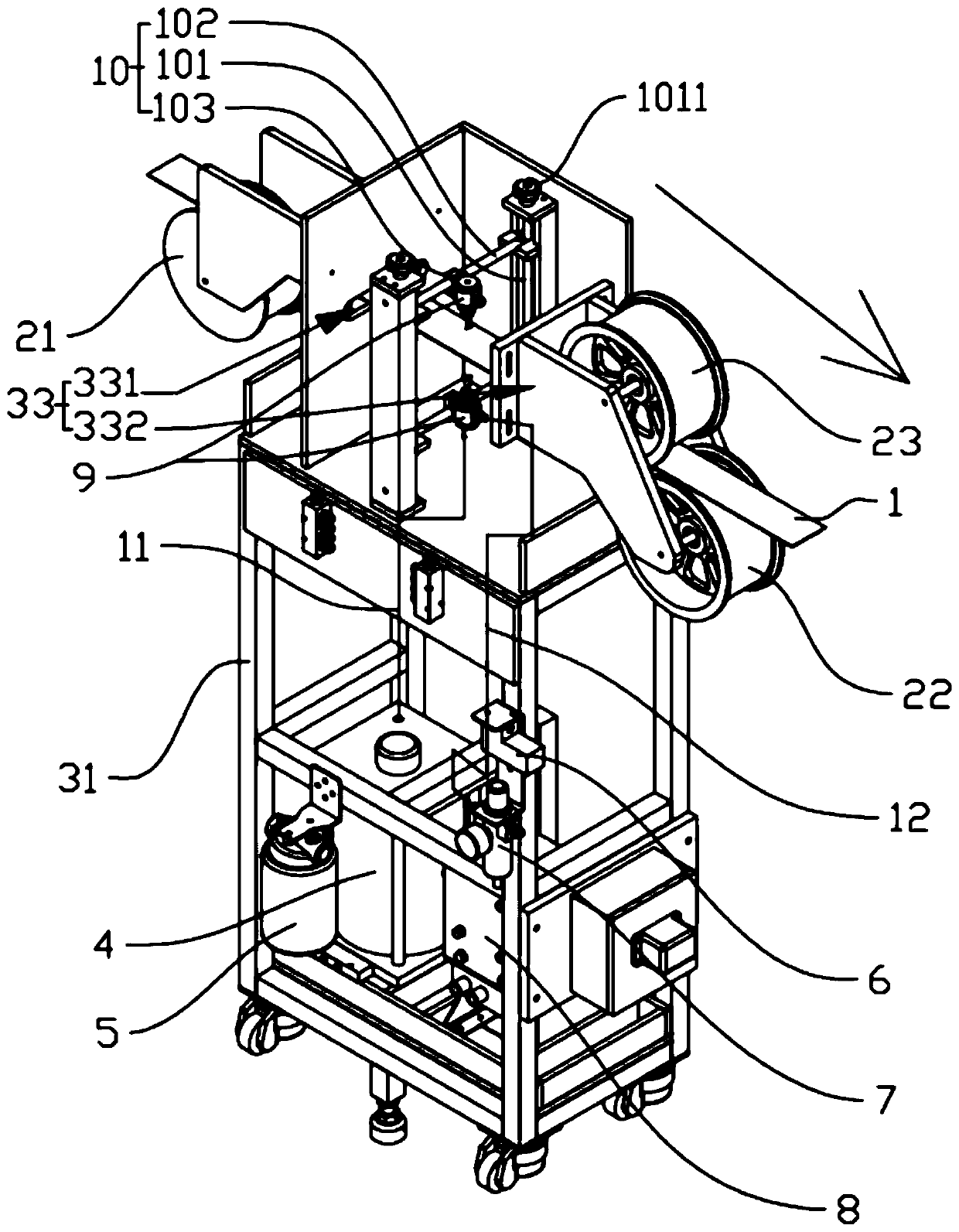

[0034] Such as figure 1 and figure 2 As shown, a fuel injection fixture for strip-shaped materials includes an organic body and a transmission device arranged on the body. It is characterized in that the body includes a frame and a closed box arranged on the frame. There is a channel for the strip material to pass through, and the transmission device allows the strip material to pass through the channel; the body is also equipped with an atomization system, which includes an oil storage tank, an oil nozzle and an air pump, and the gap between the oil injection nozzle and the air pump It is connected through the air pipe, and the air pipe is equipped with an electromagnetic control valve for on-off control. The fuel injection nozzle and the oil storage tank are connected through the oil pipe. When the air pipe is connected, the oil in the oil storage tank wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com