Machine tool oil cooling system and control method thereof

A technology of oil cooling system and machine tool, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc. problems, to achieve the effect of improving temperature control accuracy, prolonging service life, and providing machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

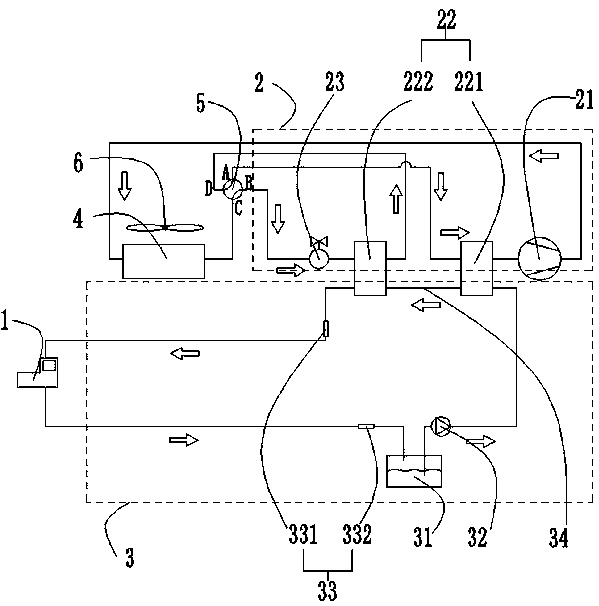

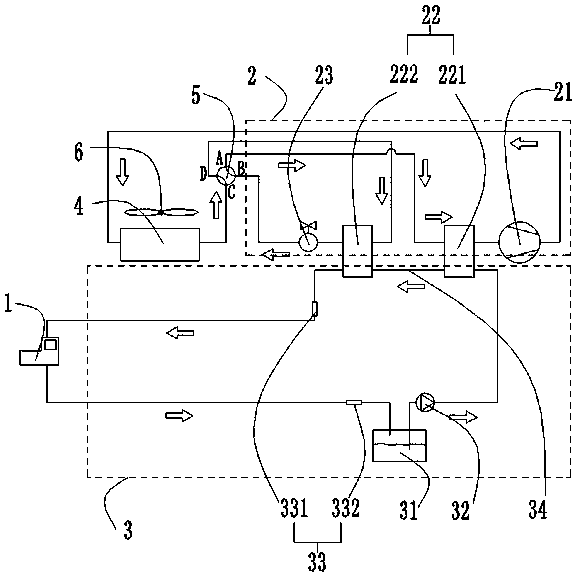

[0027] Such as Figure 1-2 As shown, the embodiment of the present invention provides a machine tool oil cooling system, including an organic machine tool 1, a refrigeration device 2, a cooling device 3, a first condenser 4, a hydraulic valve component 5 and a DC fan assembly 6, and one end of the machine tool 1 is connected to the refrigeration unit. The device 2 is connected, the other end is connected with the cooling device 3, the refrigeration device 2 is connected with the cooling device 3, one end of the hydraulic valve part 5 is connected with the refrigeration device 2, and the other end is connected with the first condenser 4, and the first condenser 4 is connected with the refrigeration device 2. The device 2 is connected, and the DC fan assembly 6 is fixed on one side of the first condenser 4, so that the machine tool can change the direction of the hydraulic valve part 5 and the speed adjustment of the DC fan assembly 6 during the working process, and change the co...

Embodiment 2

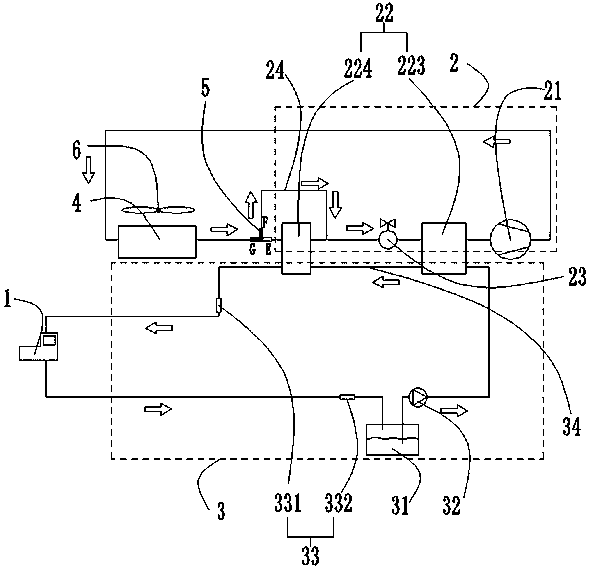

[0039] Such as Figure 3-4 As shown, the embodiment of the present invention provides a machine tool 1 oil cooling system, including an organic machine tool 1, a refrigeration device 2, a cooling device 3, a first condenser 4, a hydraulic valve component 5 and a DC fan assembly 6, and one end of the machine tool 1 is connected to the The refrigeration device 2 is connected, the other end is connected with the cooling device 3, the refrigeration device 2 is connected with the cooling device 3, one end of the hydraulic valve part 5 is connected with the refrigeration device 2, and the other end is connected with the first condenser 4, and the first condenser 4 is connected with the The refrigeration device 2 is connected, and the DC fan assembly 6 is fixed on one side of the first condenser 4, so that the machine tool can change the direction of the hydraulic valve part 5 and the speed adjustment of the DC fan assembly 6 during the working process, and change the cooling oil in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com