Paving seam prefabricated body base cloth separating device

A separation device and prefabricated technology are applied in the field of base fabric separation device and seam-laid preform base fabric separation device, which can solve the problem that it is difficult to meet the quality control requirements and mass production requirements of aerospace composite parts, the heating temperature cannot be stably controlled, and the heat The problems of long heating time of the melted yarn can achieve the effect of wide applicability, stable quality and stable separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

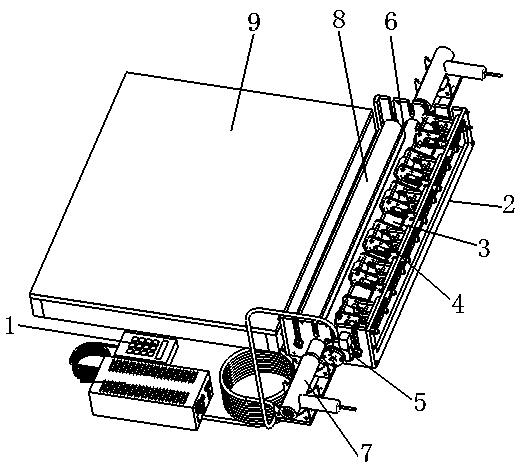

[0031] The seam-laying prefabricated body base fabric separation device is composed of a controller 1, a frame 2, a driving roller 3, a pressing wheel 4, an exhaust tube 6, a heat gun 7, and a driven roller 8.

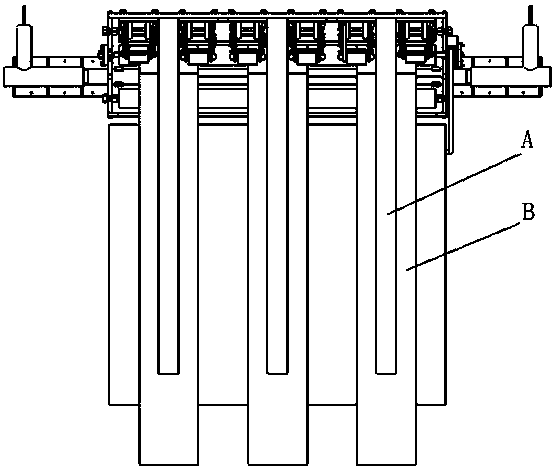

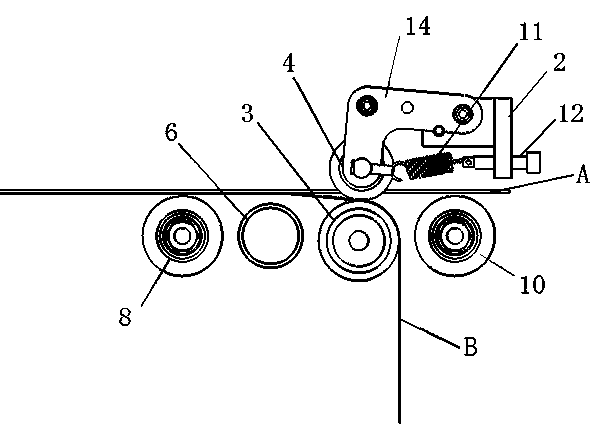

[0032] The frame 2 is the main body and provides a fixed foundation. The front side of the frame 2 is provided with a platform 9 which is level with the top surface of the drive roller 3 . The driving roller 3, the driven roller 8, and the exhaust cylinder 6 are arranged parallel to each other, the driven roller 8 is arranged on the front side of the driving roller 3, and the top of the roller is on the same horizontal plane, and the exhaust cylinder 6 is arranged on the driving roller 3 and the driven roller 8 between.

[0033] The front end shaft of the clamping arm 14 is fixed with a pinch wheel 4, and the rear end shaft is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com