Electric drive rear axle assembly

An electric drive, rear axle technology, applied in electric power units, power units, elastic suspensions, etc., can solve the problems of inability to provide space for accommodating electric drive units, long rear lower control arms and longitudinal trailing arms, and high space occupation , to achieve the effect of compact structure, vibration reduction effect and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions and advantages of the present disclosure clearer, the following further describes the embodiments of the present disclosure in detail with reference to the accompanying drawings.

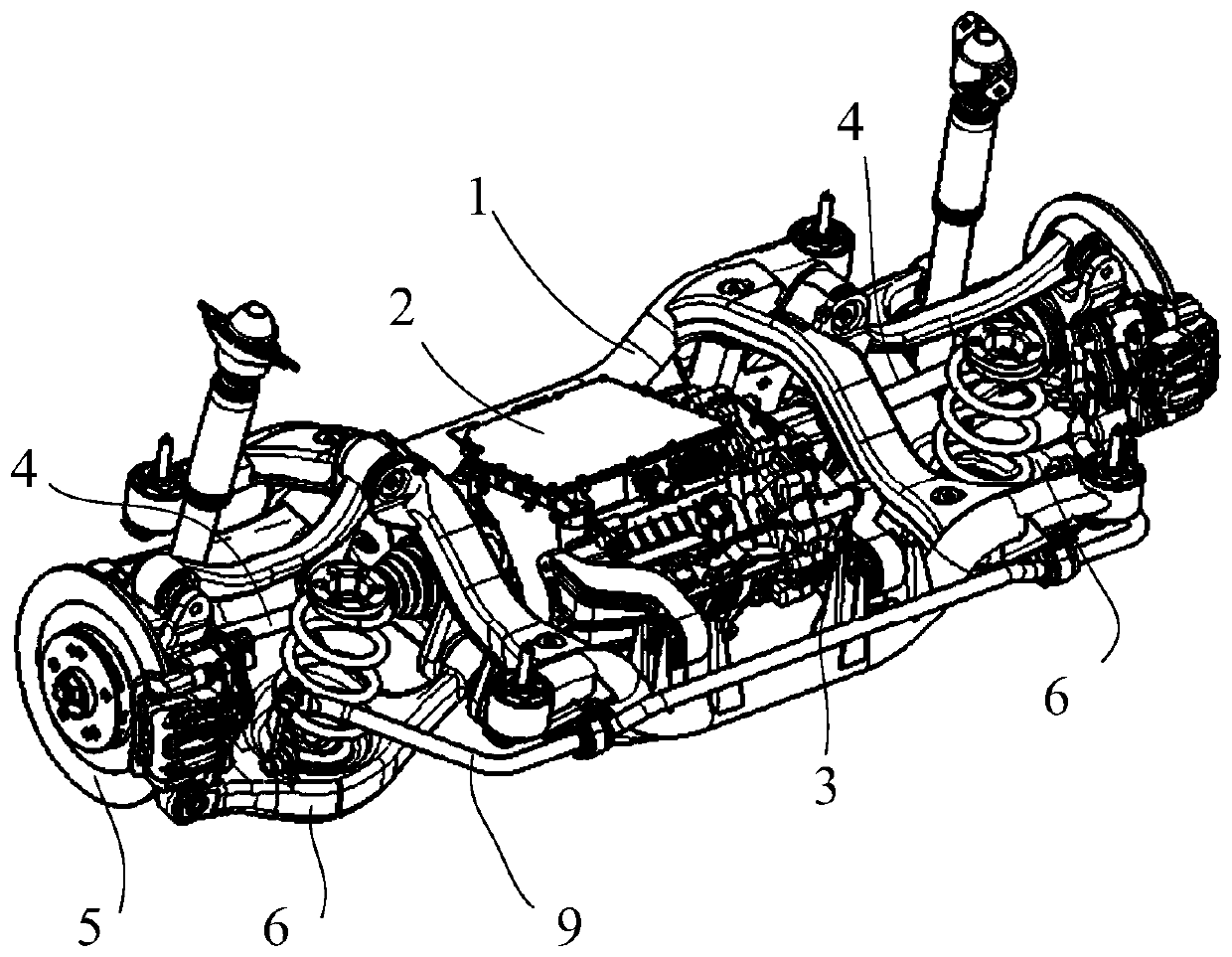

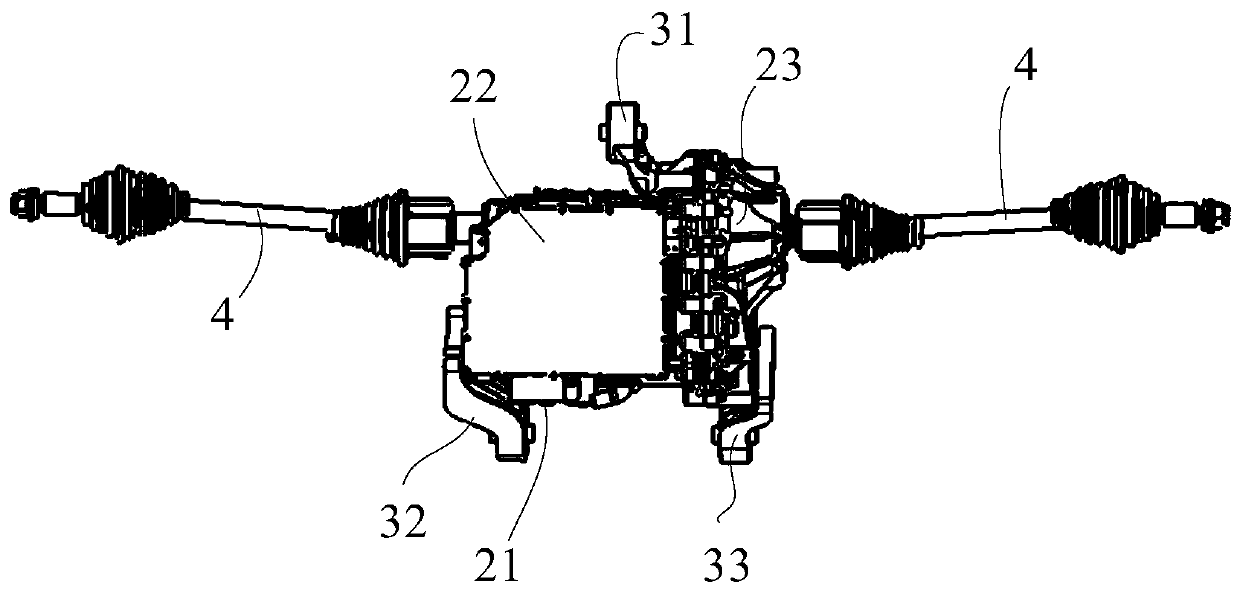

[0028] The embodiment of the present disclosure provides an electric drive rear axle assembly, which is suitable for electric vehicles. figure 1 Is the schematic diagram of the electric drive rear axle assembly, such as figure 1 As shown, the electric drive rear axle assembly includes a rear subframe module 1, an electric drive module 2, a rear suspension module 3, a rear drive shaft module 4, a rear brake claw module 5, and a rear suspension module 6.

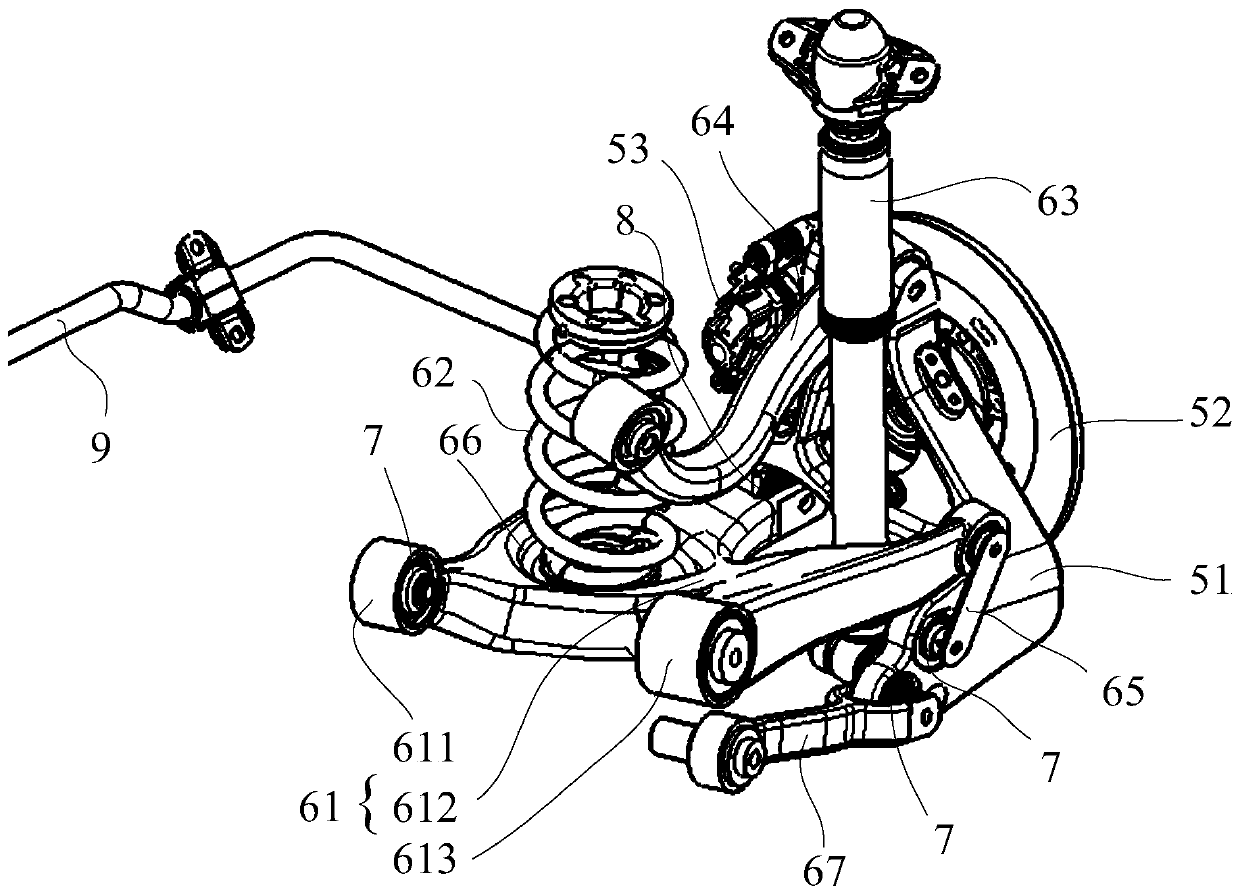

[0029] figure 2 Is the structural diagram of the rear suspension module, combined with figure 2 In this embodiment, the rear suspension module 6 includes an H-shaped control arm 61, a rear coil spring 62, a rear shock absorber 63, a rear upper control arm 64, a bridge rod 65, and a toe adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com