Self-insulation zigzag concrete slab girder hinge joint structure

A zigzag and concrete technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of slab girder safety, durability reduction, lower overall performance of slab girder, insufficient lateral force transmission capacity, etc., to reduce water accumulation , reduce the effect of staggering between slabs and girders, and reduce freeze-thaw damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

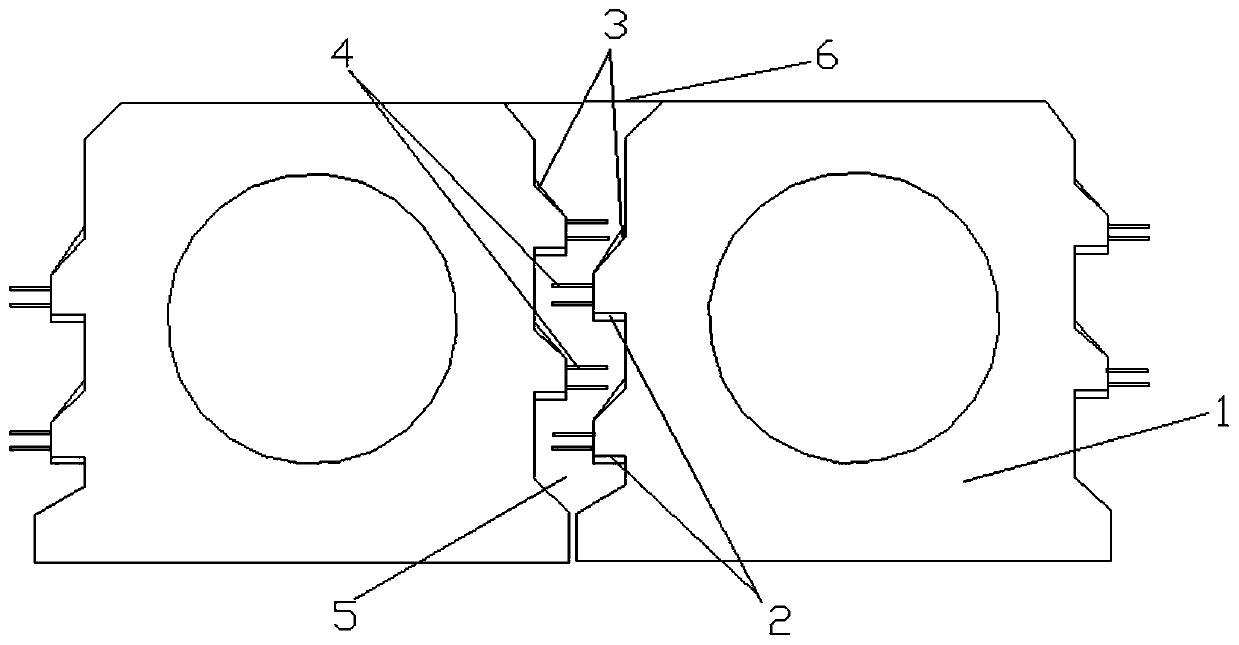

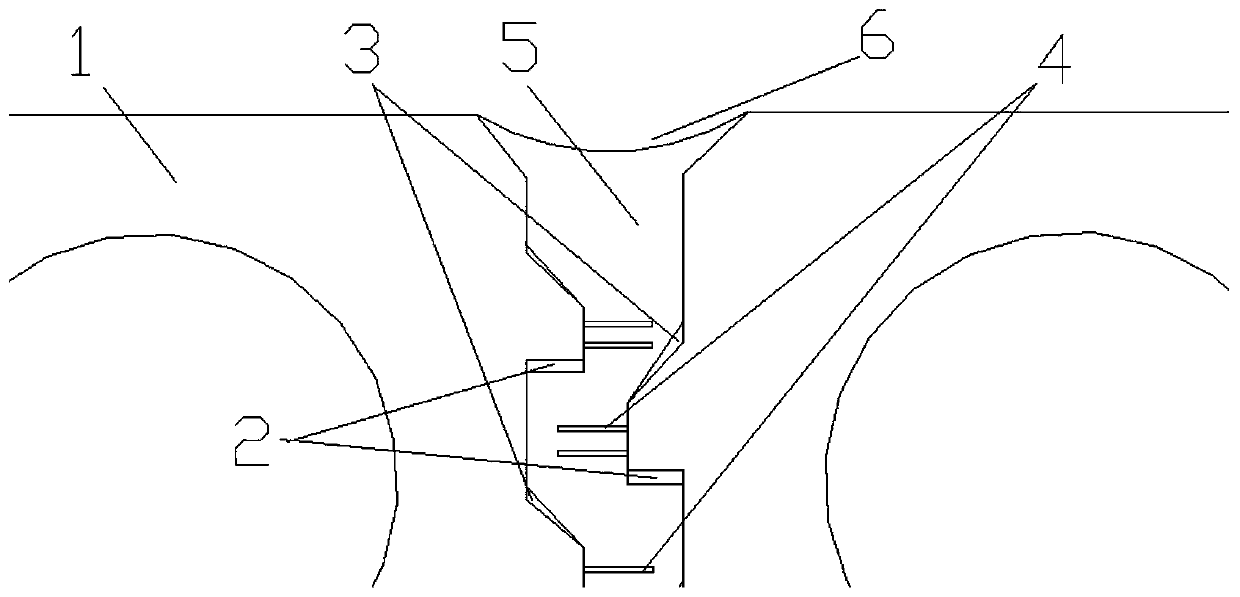

[0026] Such as figure 1 As shown, a self-insulating zigzag concrete slab hinge joint structure of the present invention includes a zigzag slab girder 1, a vibration induction heating plate 2, a smooth coating 3, double rows of steel bars 4, hinge gaps 5 and a waterproof diaphragm 6,

[0027] The serrations of the zigzag plate girder 1 are staggered from each other, the vibration induction heating plate 2 is pasted under the serrations, the smooth paint 3 is applied on the top of the serrations, the double row of steel bars 4 are inserted horizontally inside the serrations to form a zigzag hinge gap 5, and the After the seam concrete is poured, one deck waterproof membrane 6 is coated above it.

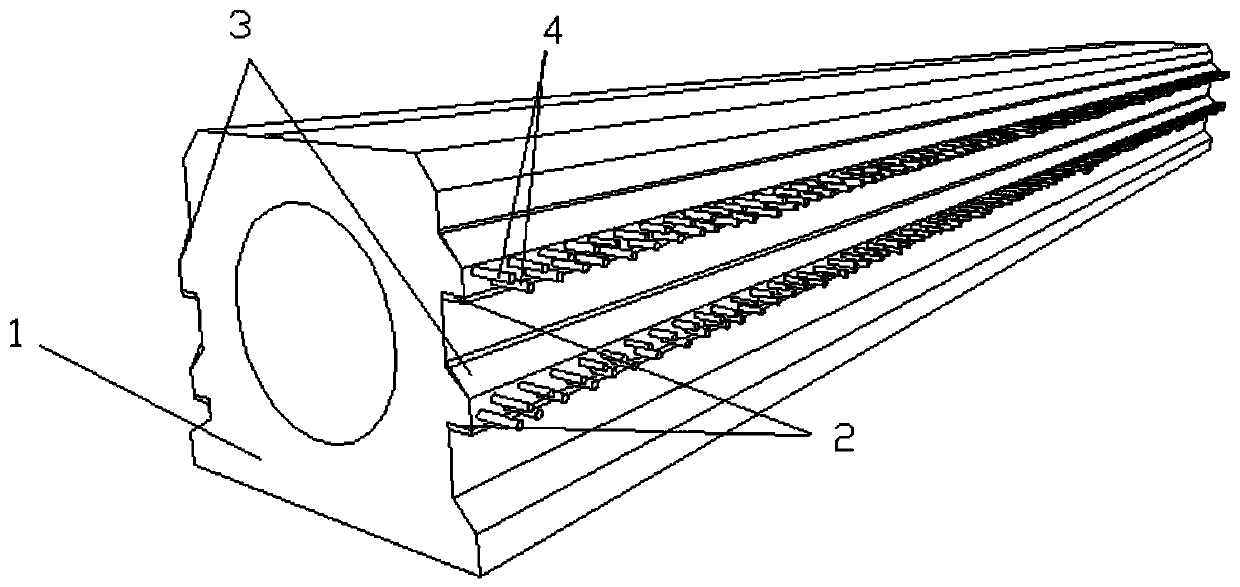

[0028] Such as figure 2 As shown, the double-row steel bars 4 are arranged horizontally inside the sawtooth slab girder 1 when pouring the sawtooth slab girder 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com