Shield tunnel segment assembling positioning device and shield tunnel segment assembling process

A shield tunnel segment and positioning device technology, which is applied in tunnels, tunnel linings, optical device exploration, etc., can solve the hidden dangers of long-term structural safety and operation and maintenance of tunnels, cracking of concave and convex tenon concrete of segments, and difficulty in ensuring assembly quality and other problems, to achieve the effect of improving assembly quality and assembly efficiency, low construction process requirements, and convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

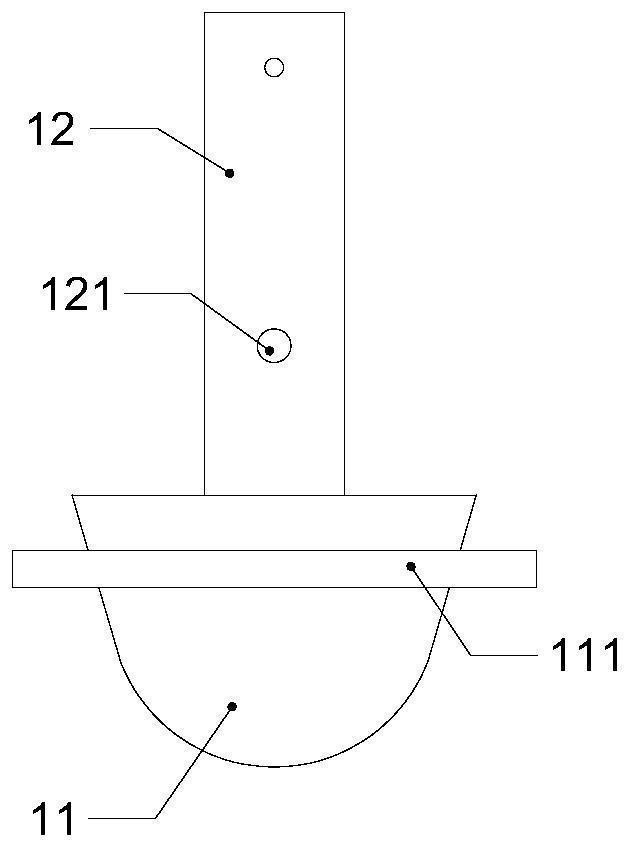

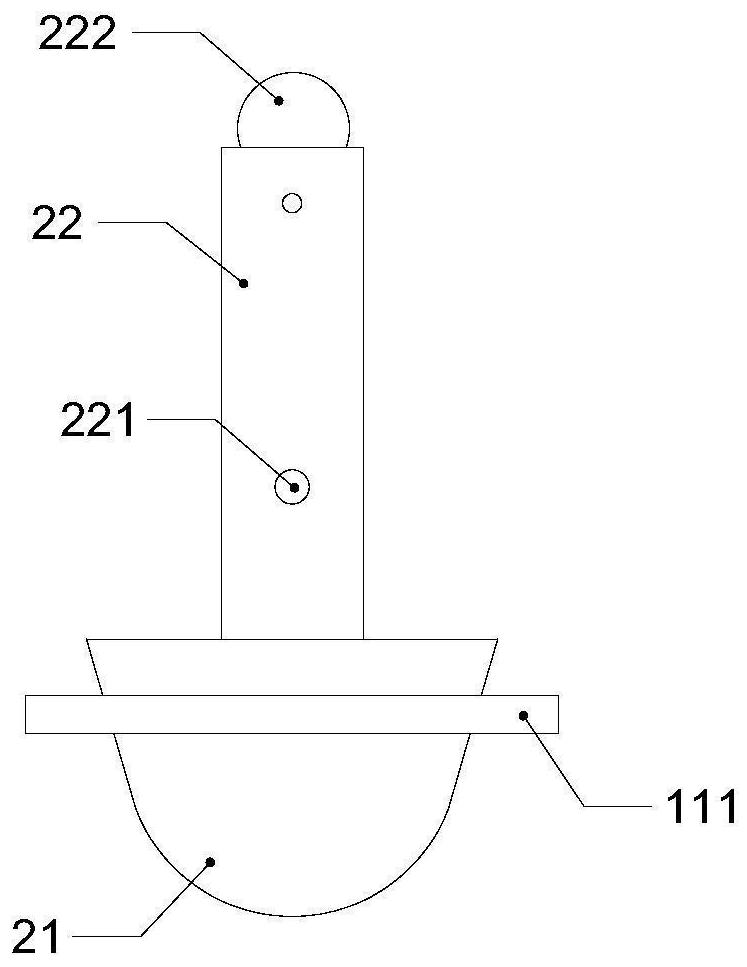

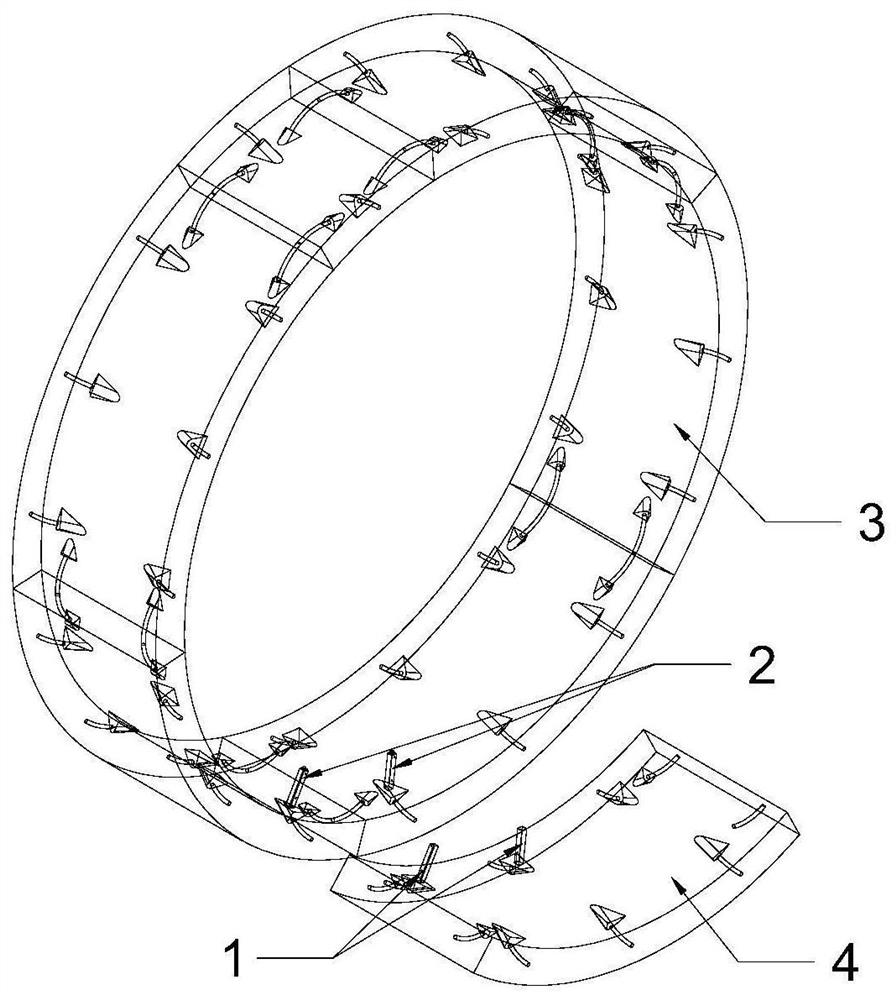

[0039] refer to figure 1 and figure 2, a segment assembly and positioning device for a shield tunnel, including: a laser emitting part 1 and a laser receiving part 2 paired with the laser emitting part 1, the laser emitting part 1 includes: a first fixing support that matches the upper hand hole of the segment The base 11 and the laser emitter 12 arranged on the first fixed support 11, the laser receiver 2 includes: the second fixed support 21 matched with the upper hand hole of the tube sheet and the laser light set on the second fixed support 21 Receiver 22. Before construction, the shield tunnel segment should be designed according to engineering geological and hydrological conditions, tunnel depth, tunnel diameter, construction requirements, etc., and the first fixed support can be further designed according to the hand hole size of the segment. The size of the base and the second fixed support, and the bottom of the laser transmitter 12 and the laser receiver 22 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com