Pump body assembly, rotary compressor and air conditioner

A technology of rotary compressors and components, applied in the direction of rotary piston machinery, rotary piston pumps, pump components, etc., can solve problems such as reducing the oil discharge rate of the compressor, and ensure effective lubrication, reduce mechanical noise, reduce Effects of reliability risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

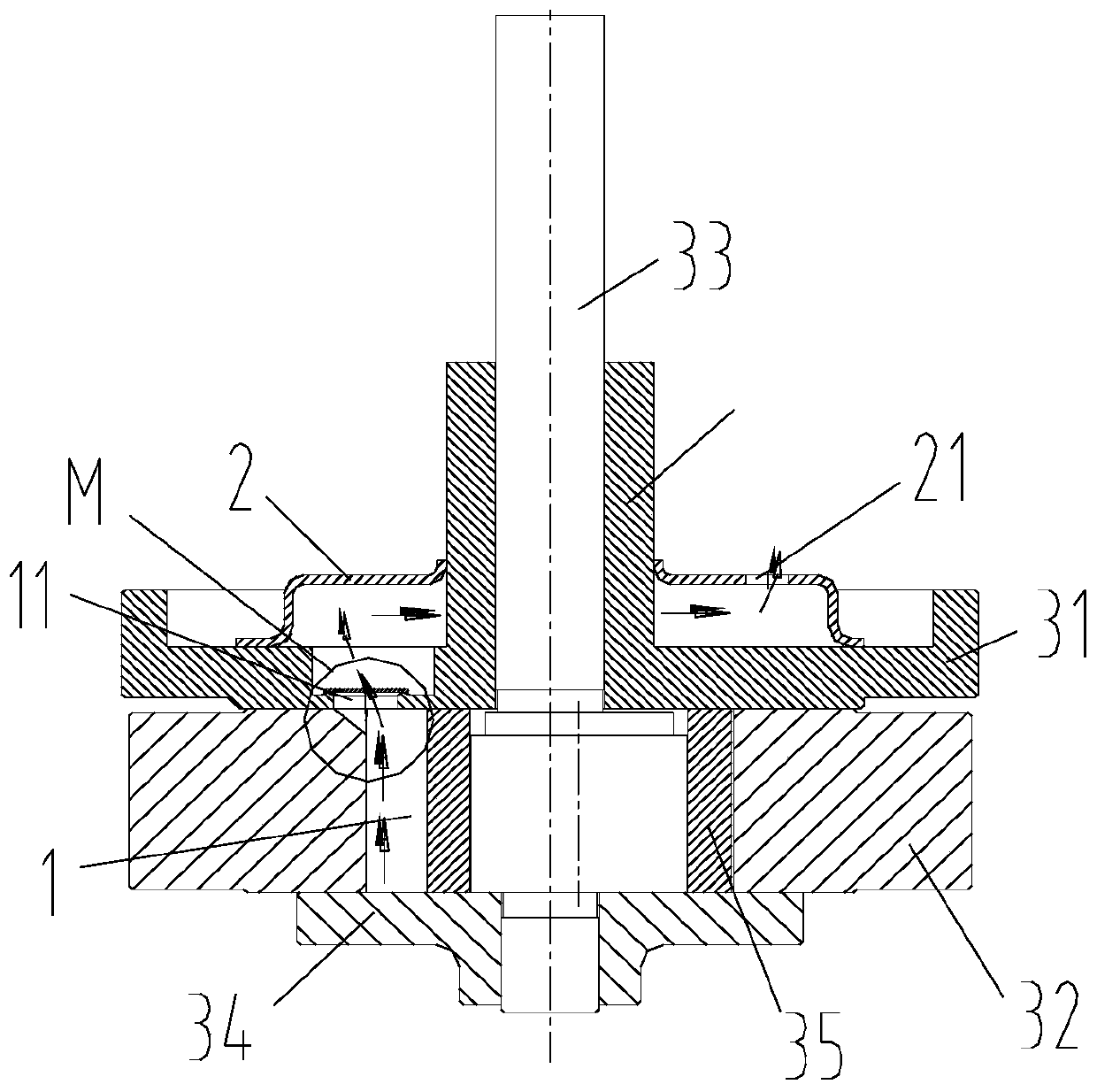

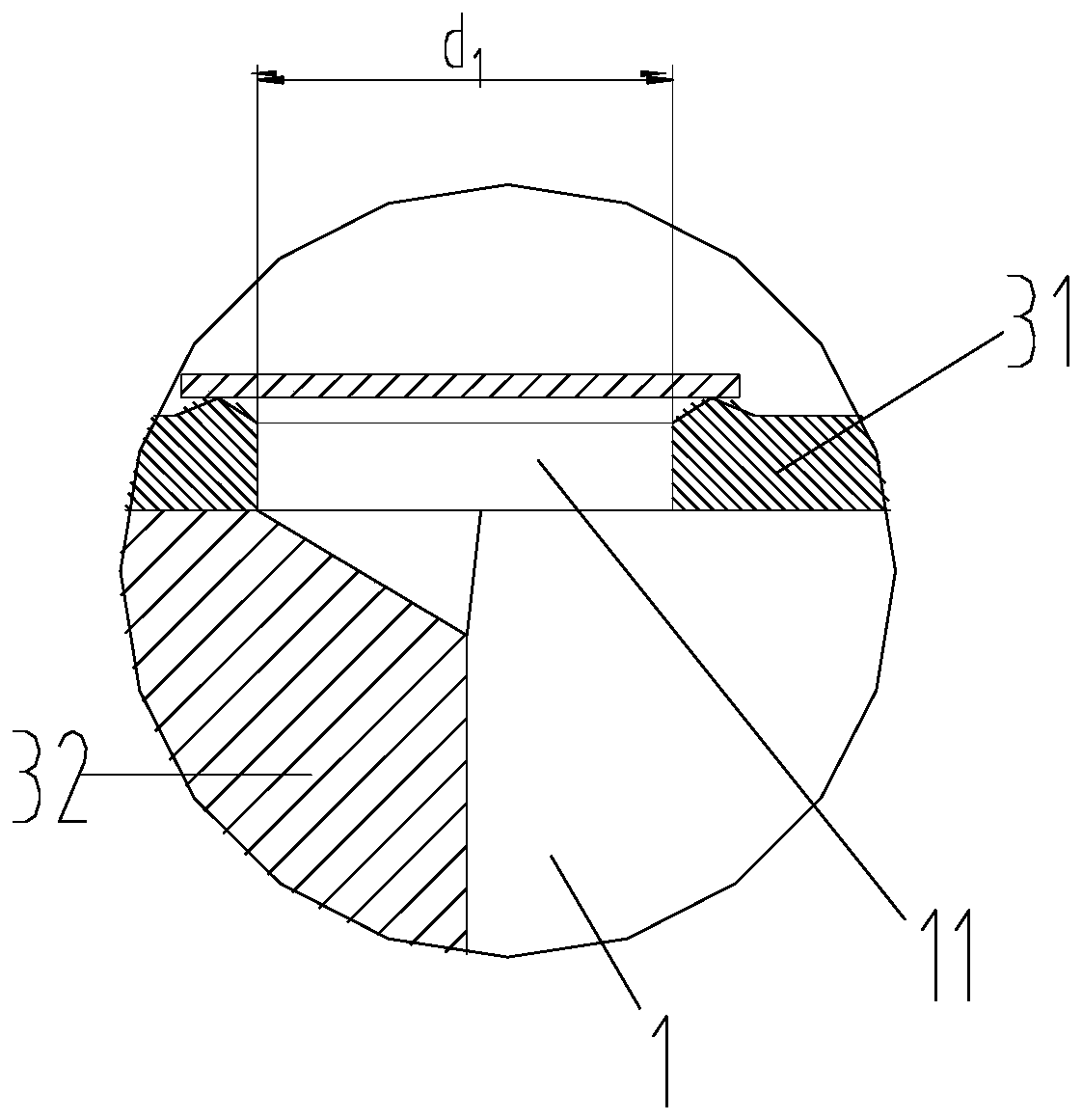

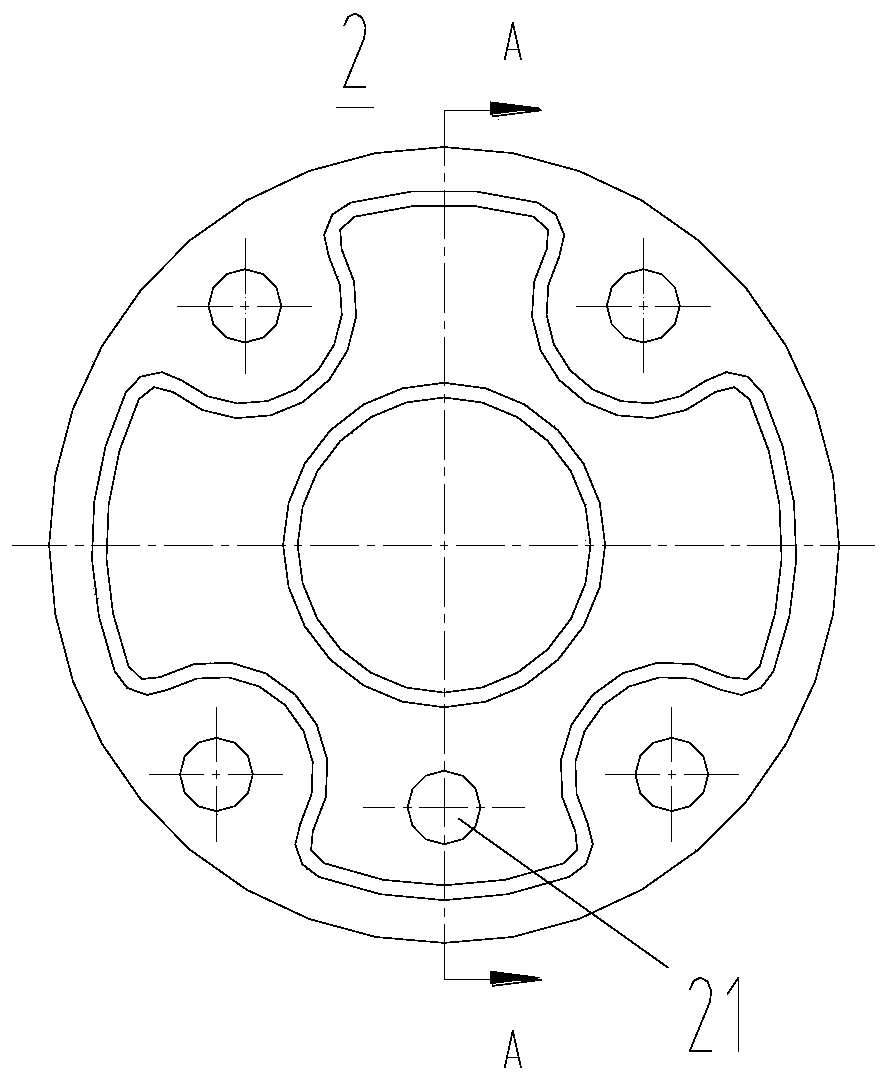

[0026] see in conjunction Figure 1 to Figure 8 As shown, according to an embodiment of the present invention, a pump body assembly is provided, including a first flange 31, a second flange 34, a first cylinder 32, a crankshaft 33, and a sliding vane (not shown in the figure), the The first cylinder 32 has a hollow structure, the first flange 31 and the second flange 34 are located at both ends of the first cylinder 32 in the axial direction, and the crankshaft 33 passes through the first flange 31 and the second flange 34, and the crankshaft 33 has an eccentric portion, the eccentric portion is covered with a first roller 35, and the sliding plate is slidably connected to the chute of the first cylinder 32 Among them, the end of the sliding piece is connected to the outer peripheral wall of the first roller 35 by friction, so that the hollow structure is divided into an air suction chamber (low pressure chamber) and an exhaust chamber 1 (high pressure chamber). The exhaust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com