A crystal oscillator frequency debugging system

A technology of crystal oscillators and debugging systems, applied in automatic control of power, electrical components, etc., can solve problems such as relatively high welding technology requirements, hidden dangers left by products, and low production efficiency, so as to reduce reliability risks, fast and accurate Frequency accuracy debugging and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

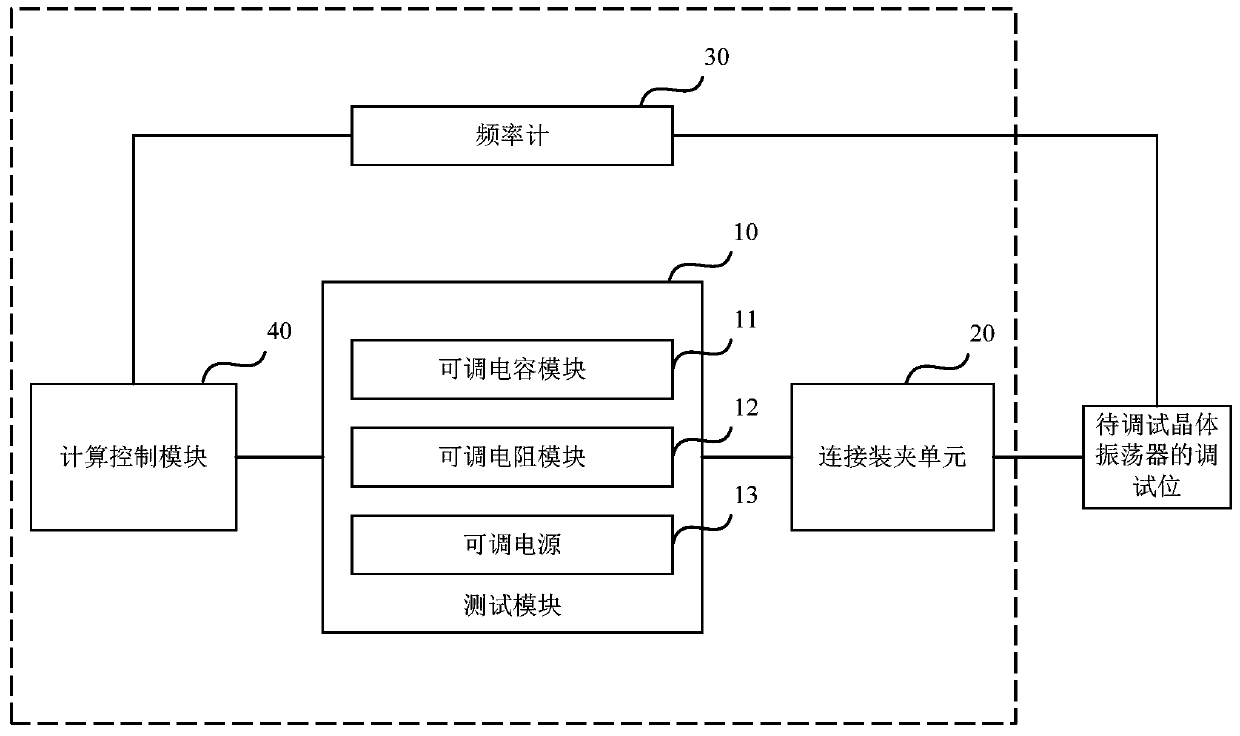

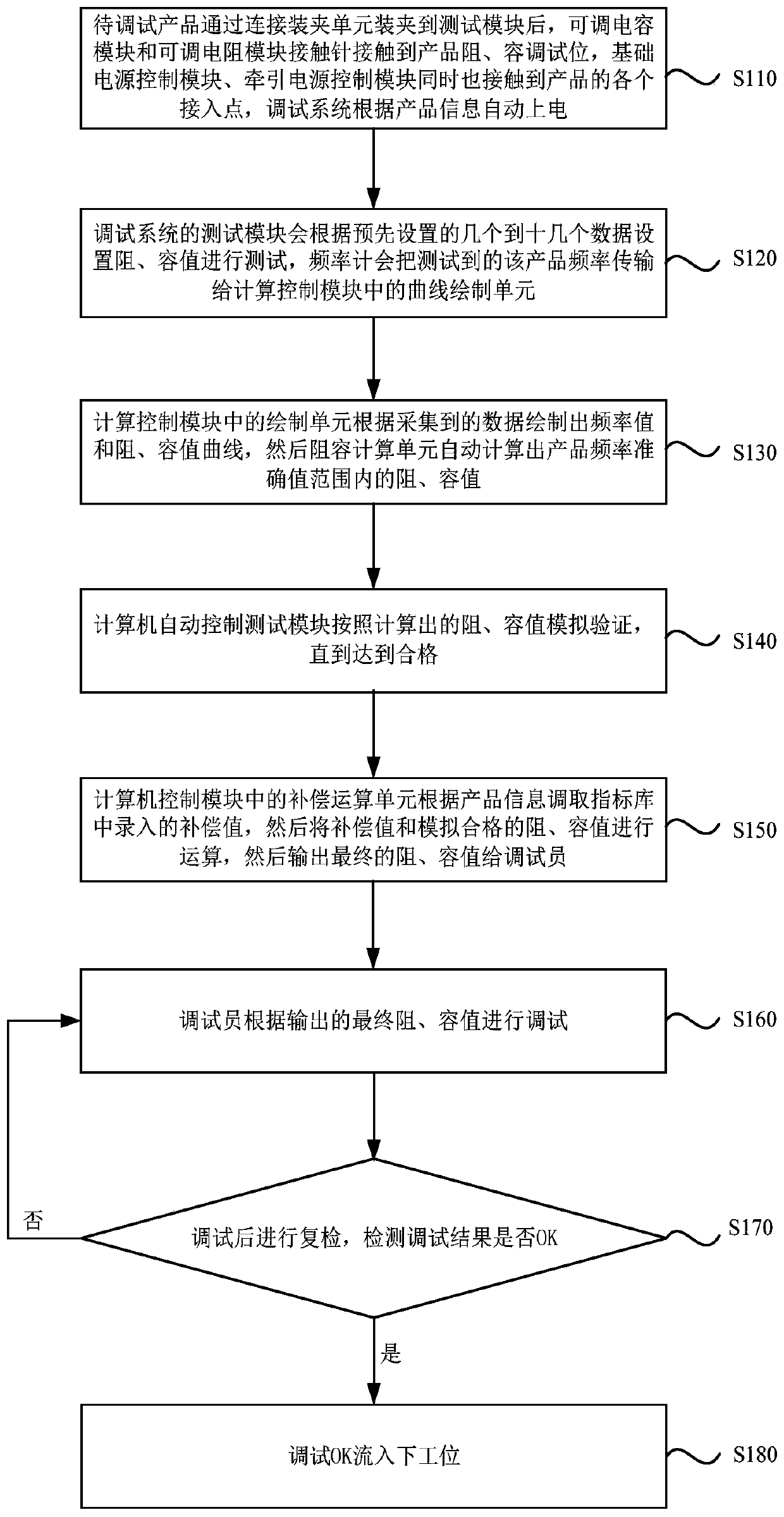

[0032] figure 1 It is a schematic diagram of a crystal oscillator frequency debugging system provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a crystal oscillator frequency debugging system. By simulating and changing the resistance and capacitance parameters of the debugging bit of the crystal oscillator to be debugged, fast and accurate frequency accuracy debugging is realized, which solves the problem of the operator in the debugging process. The potential safety hazards and low production efficiency caused by repeated welding to the product.

[0033] The crystal oscillator frequency debugging system includes a test module 10, including an adjustable capacitor module 11, an adjustable resistance module 12 and an adjustable power supply 13;

[0034] Connect the clamping unit 20, the input end of the connecting clamping unit 20 is respectively connected to the output end of the adjustable capacita...

Embodiment 2

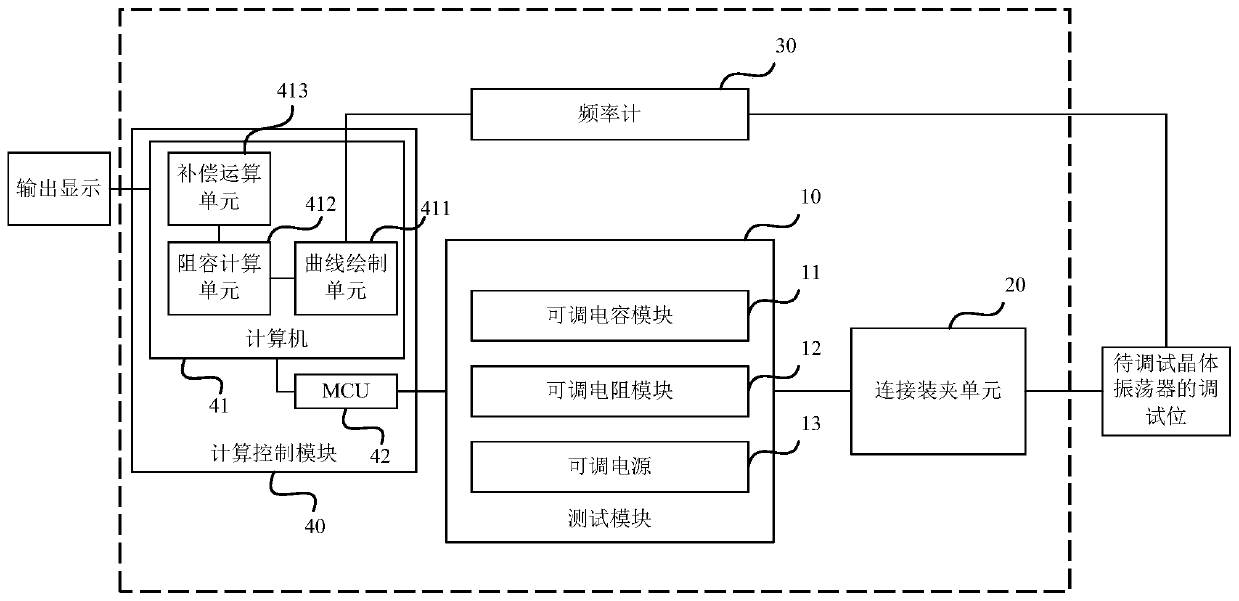

[0053] figure 2 It is a schematic diagram of a crystal oscillator frequency debugging system provided by Embodiment 2 of the present invention. The system is based on the first embodiment, the calculation control module 40 includes a computer 41, MCU42; the computer 41 can realize the following functional units through software and / or, the functional units include a curve drawing unit 411, a resistance-capacitance calculation The unit 412 preferably also includes a compensation calculation unit 413 .

[0054] The compensation calculation unit 413 is connected to the resistance-capacity calculation unit 412, and is used to retrieve the compensation value entered in the index library according to the information of the crystal oscillator to be debugged, and use the compensation value to calculate the target resistance and the target resistance. The capacitance is compensated.

[0055] It should be noted that since the actual resistance-capacitance effect of the product is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com