Anti-cavitation centrifugal pump and manufacturing method thereof

A technology for centrifugal pumps and pump casings, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, and can solve cavitation unstable flow, blade channel distortion, and severe fluctuations in system flow and pressure, etc. problem, achieve the effect of reducing the unstable state, ensuring the installation accuracy and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

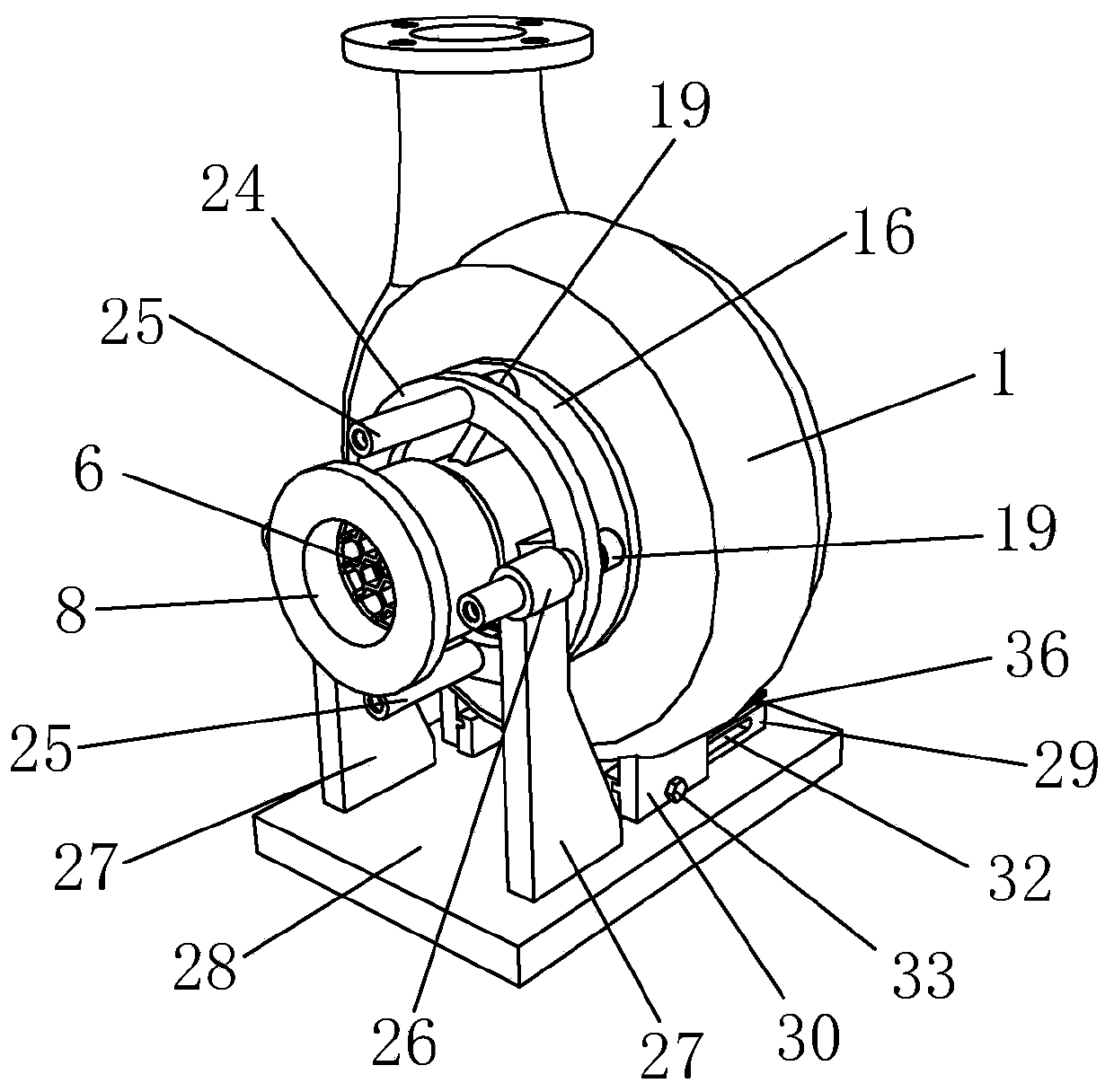

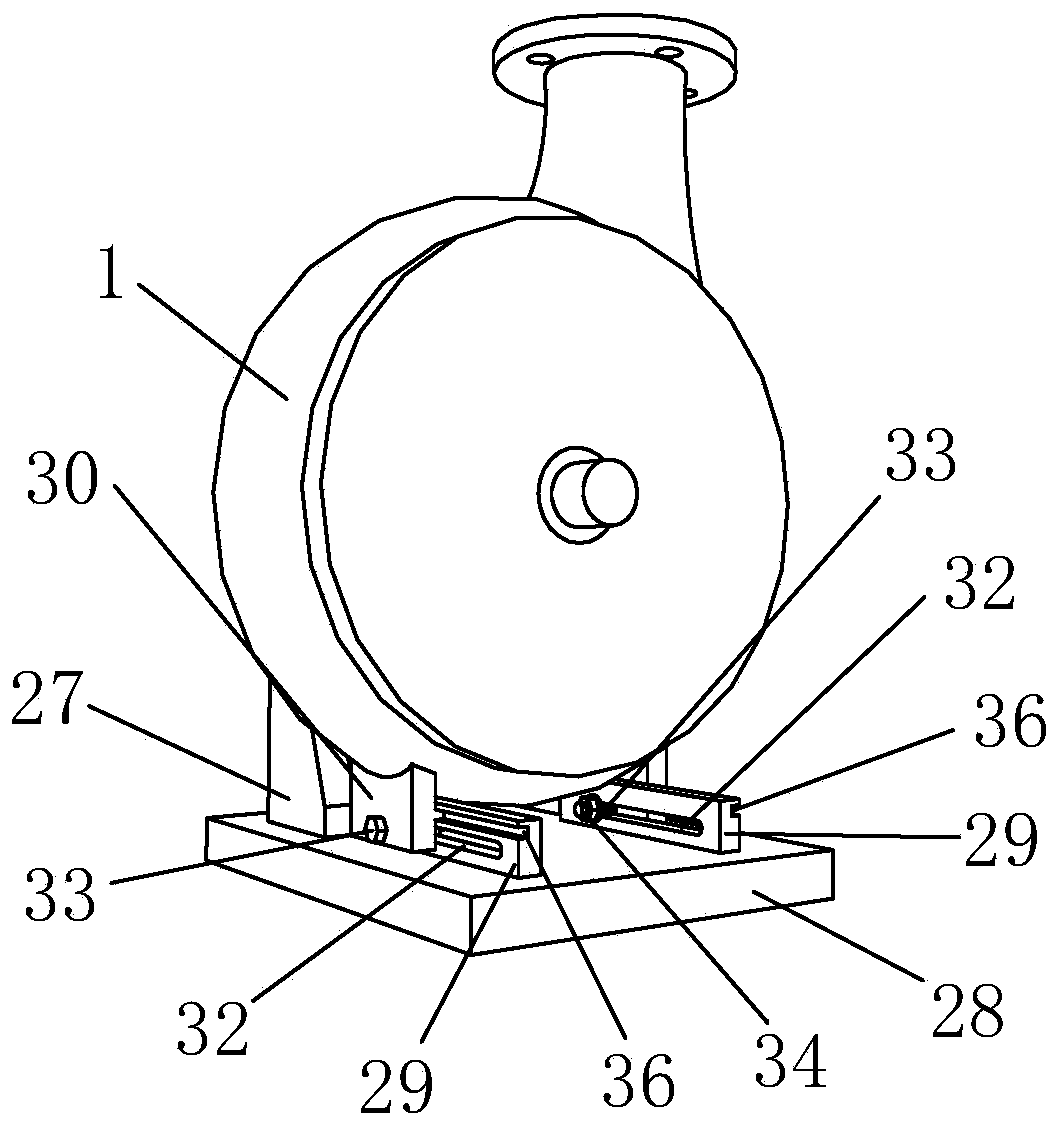

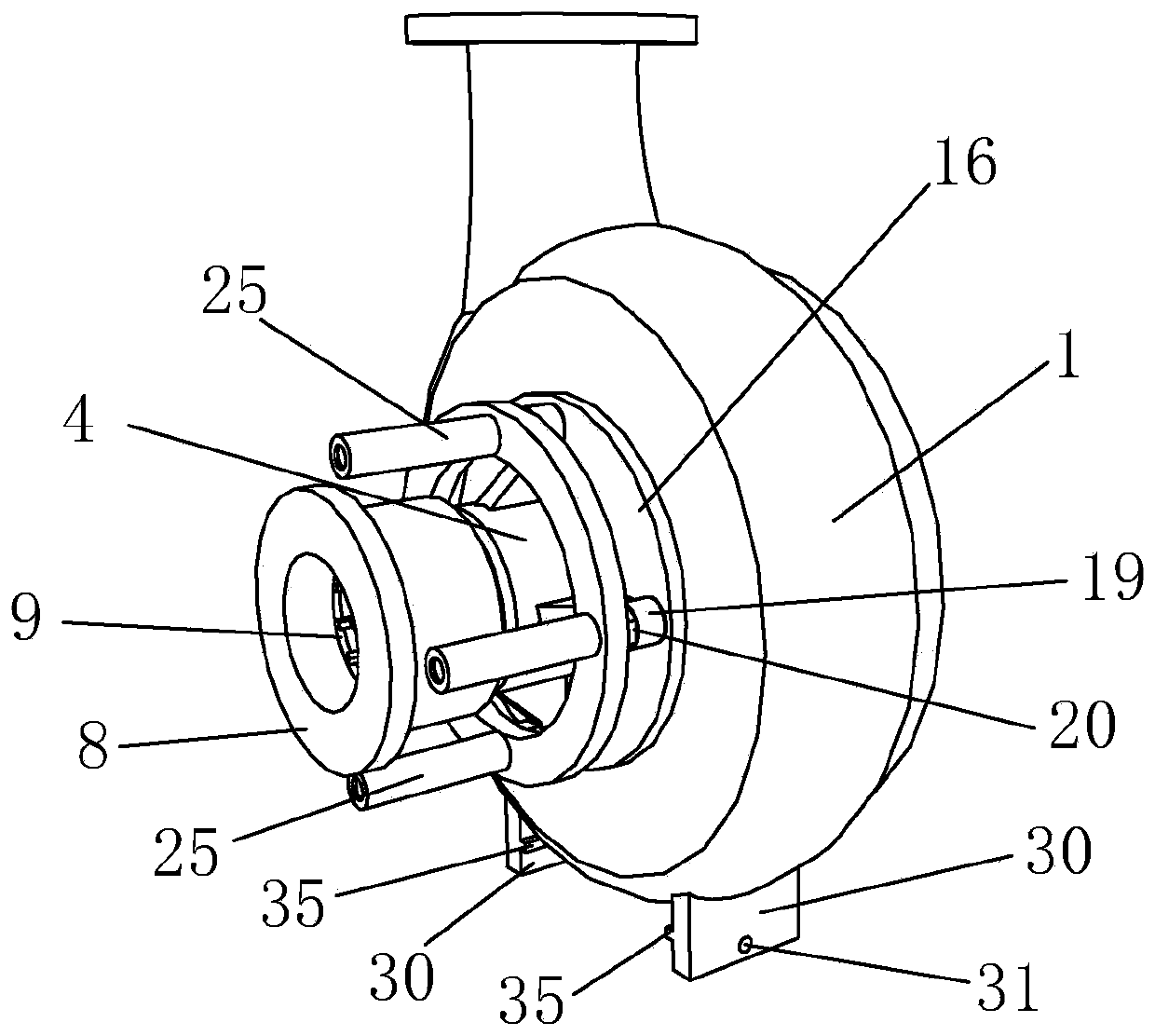

[0038] like Figure 1 to Figure 8 As shown, it is an anti-cavitation centrifugal pump of the present invention, comprising a pump casing 1, an impeller 2 and an inducer 3, the impeller 2 is arranged in the pump casing 1, the pump casing 1 is provided with a water inlet jacket 4, and the inducer 3 is arranged In the water inlet jacket 4, it is characterized in that: it also includes a support ring 5, the support ring 5 is provided with a deflector 6, the water inlet jacket 4 is provided with a groove 7, the support ring 5 is arranged in the groove 7, and the water inlet jacket 4. A clamping ring 8 is threadedly connected, the support ring 5 is provided with a clamping ring 9, and the clamping ring 8 clamps the clamping ring 9. By setting the deflector 6 on the water inlet jacket 4, the flow field of the water inlet jacket 4 can be made uniform, the backflow area can be reduced, the unstable state induced by rotating cavitation can be effectively reduced, and the stable operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com