Worm and gear gear reducer for travelling in steel mill

A worm gear, gear reduction technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission parts, etc., can solve the problem of inability to take into account power transmission, and achieve the effect of improving transmission stability, torque and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be made below in conjunction with drawings and embodiments.

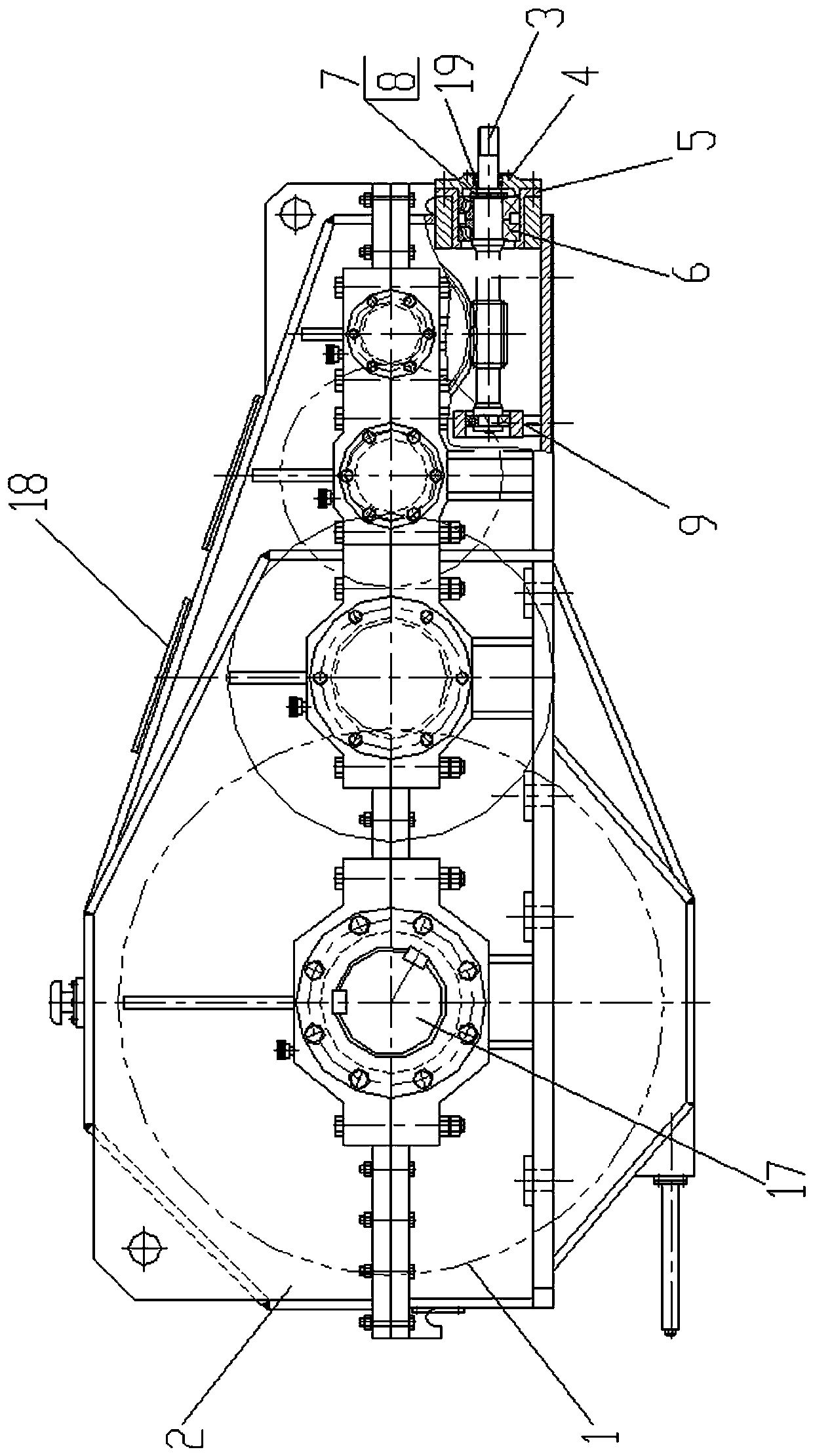

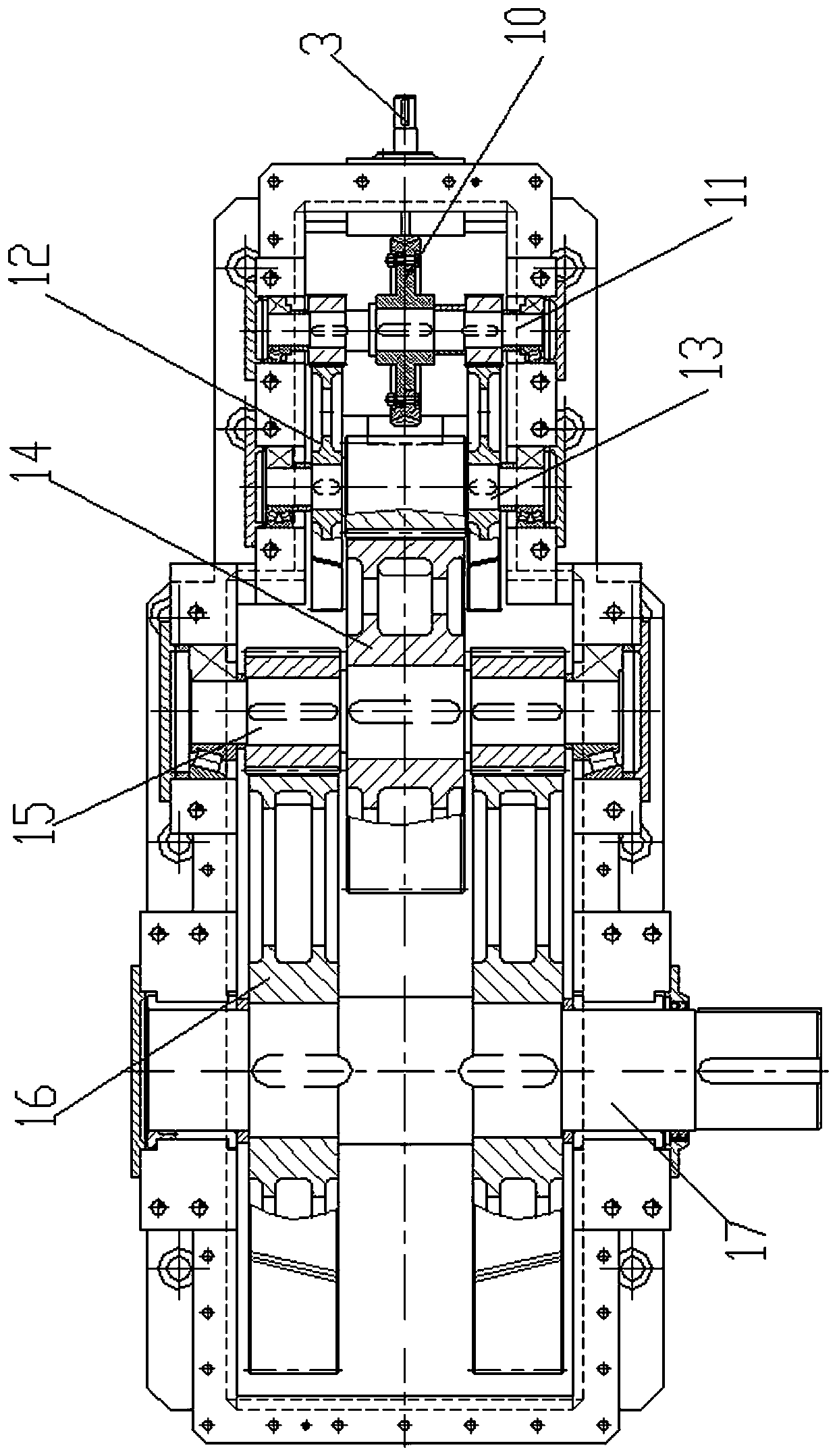

[0013] figure 1 , 2 Shown: a worm gear reducer used for walking in steel mills, including a lower box 1 and a box cover 2, the box cover seals the lower box to form a box, the box shrinks from left to right, and the box tilts to shrink There is a mirror hole 18 on the cover of the box, the right end of the lower box 1 is connected to the input worm 3, the input worm is supported on the right side of the lower box through the bearing seat 5 and the bearing 6, and the inner end of the input worm is supported by the support in the lower box On the seat 9, the inner side of the bearing is limited against the inner step on the input worm, and the outer side of the input worm is screwed to the outer side of the input worm through the stop washer 7 and the round nut 8 to lock and crimp the outer side of the bearing 6, and the outer side of the bearing is also threaded on the input worm The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap