5G filter ceramic appearance machine vision detection device

A machine vision detection and filter technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to meet parts supply requirements, inconsistent judgment standards, slow pace, etc., to save labor costs and reduce detection costs , The effect of shortening the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For ease of description, the present invention is described in detail by the following specific embodiments and drawings.

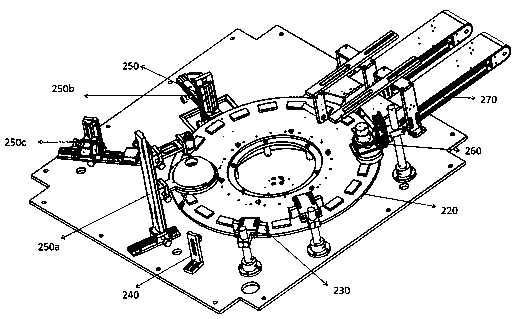

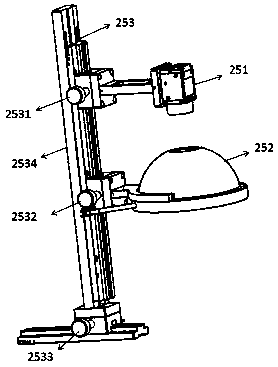

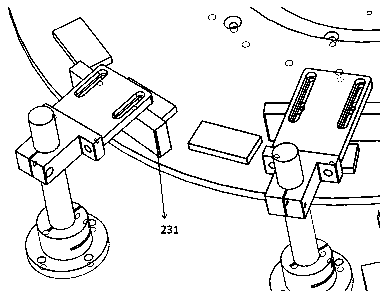

[0024] A 5G filter ceramic appearance machine vision inspection device, including a circuit control system, a mechanical operation system, and an image processing system; the circuit control system includes a power switch, a blow valve regulator and a PLC controller, the PLC controllers are respectively Connect with the mechanical operation system and the image processing system to form communication; figure 1 As shown, the mechanical operation system includes a glass turntable 220, and a feeding device (not shown in the figure), a material sorting device 230, a sensing device 240, and three photographing devices are sequentially arranged along the circumference of the glass turntable 220. The device 250, the cleaning device 260 and the unloading device 270, one ends of the loading device and the unloading device 270 are respectively connected to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com