Vacuum high-low temperature semiconductor device test probe station

A test probe, high and low temperature technology, applied in the field of vacuum high and low temperature semiconductor device test probe station, can solve the problems of troublesome replacement, low replacement efficiency, and inaccurate measured results, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

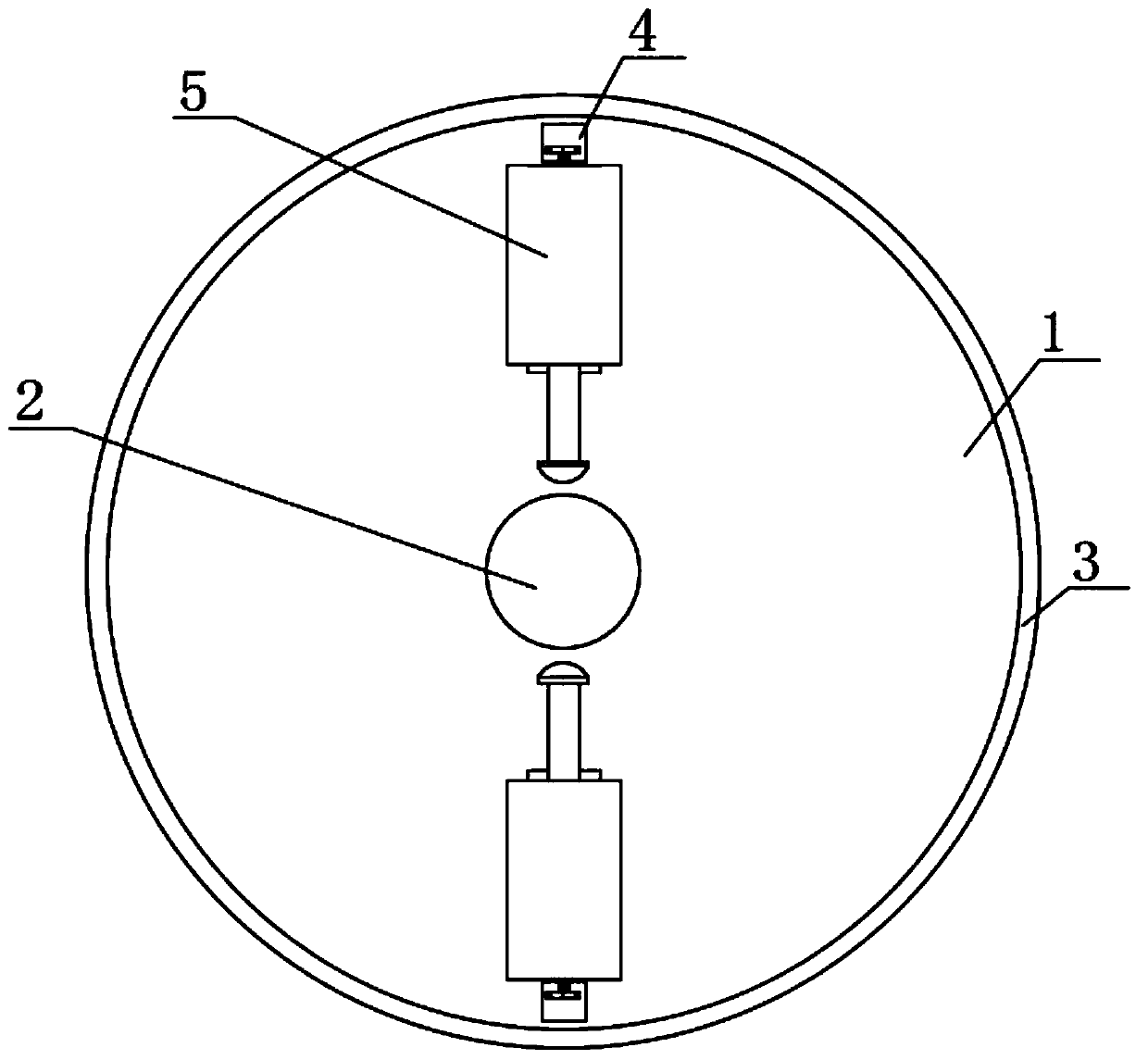

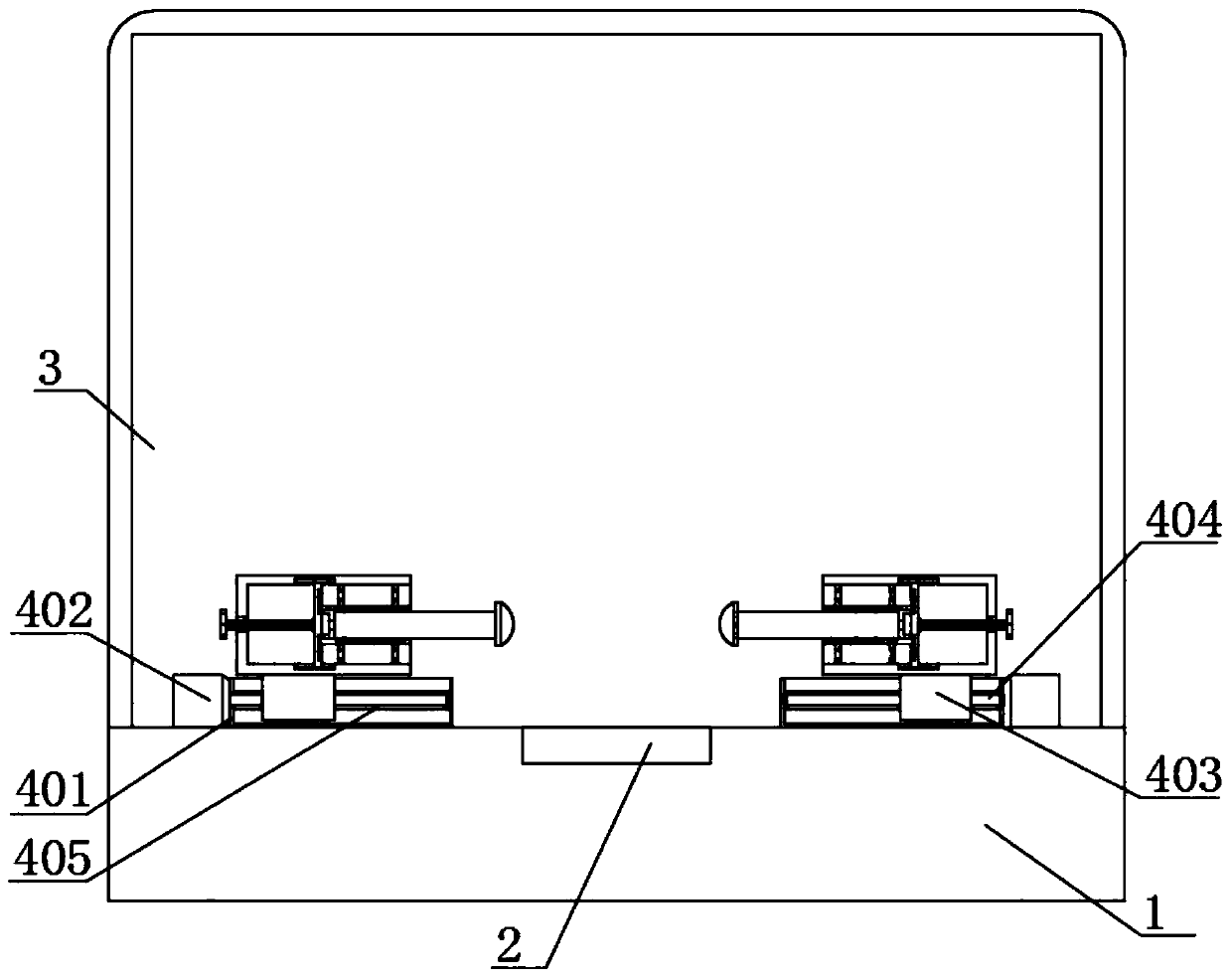

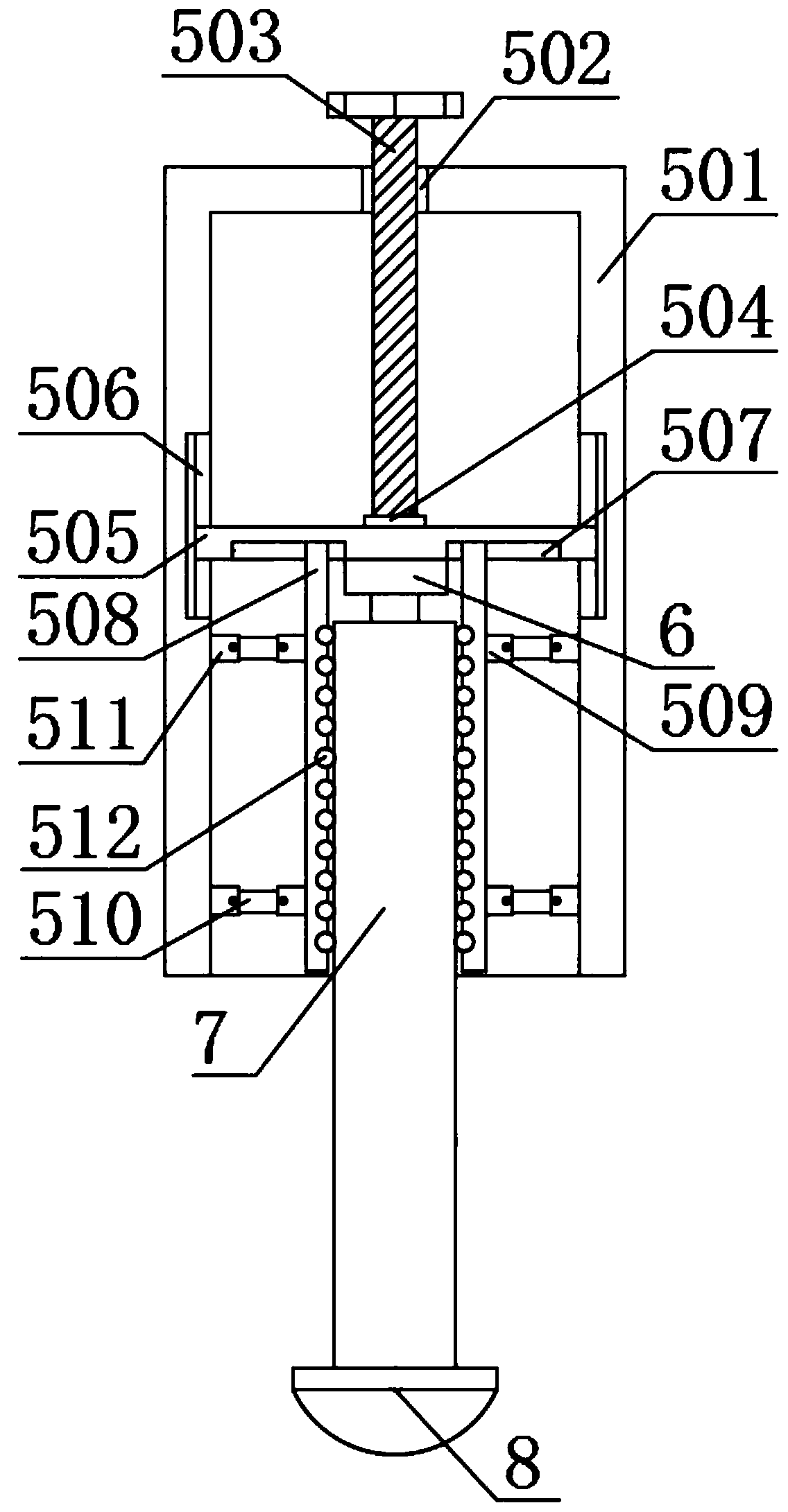

[0023] Such as Figure 1-5 As shown, the embodiment of the present invention provides a vacuum high and low temperature semiconductor device test probe station, including a workbench body 1, a protective cover 3, a probe rod 7 and a probe head 8, and the center of the top surface of the workbench body 1 is opened There is a placement groove 2, and the workbench body 1 and the protective cover 3 are clamped. By setting the placement groove 2, the semiconductor device is placed inside the placement groove 2, so as to facilitate the positioning of the semiconductor device. The two ends of the top surface of the workbench body 1 Both are fixedly connected with a moving mechanism 4, and the two moving mechanisms 4 all include a moving box 401, and the sides of the two moving boxes 401 away from each other are fixedly connected with a micromotor 402, and the micromotor 402 of the present invention uses a 5LK60W micromotor. The output end of the motor 402 is fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com