Feed refining device for pig industry

A technology for raising pigs and feeds, applied in the field of animal husbandry and breeding, can solve problems such as unsatisfactory refinement effect, and achieve the effects of improving the fragmentation effect, expanding the scope of action, and improving the degree of refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

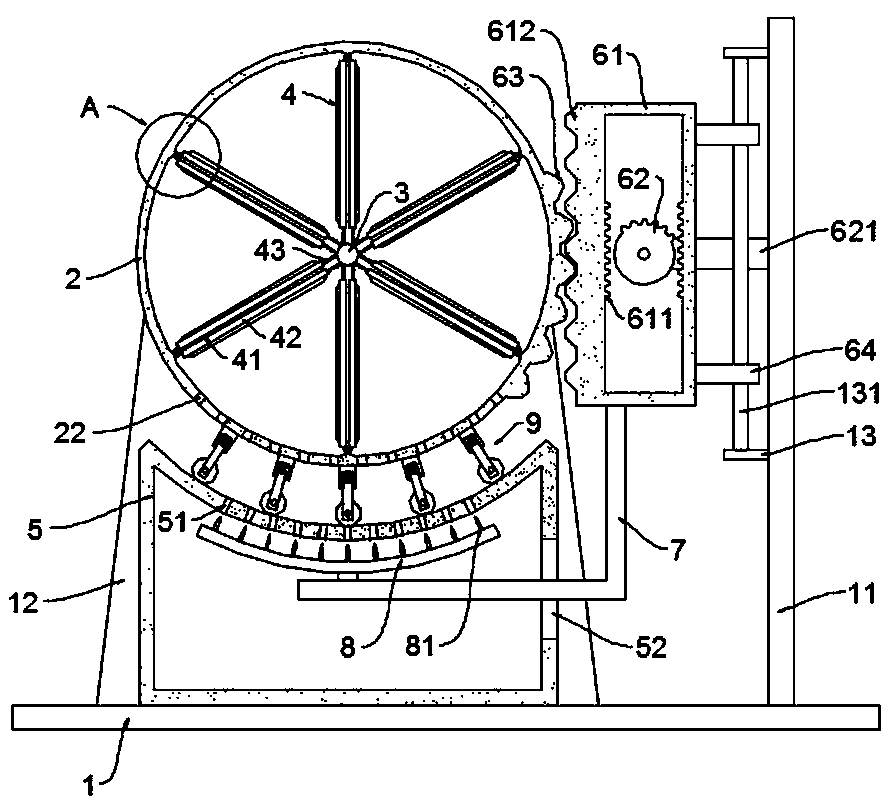

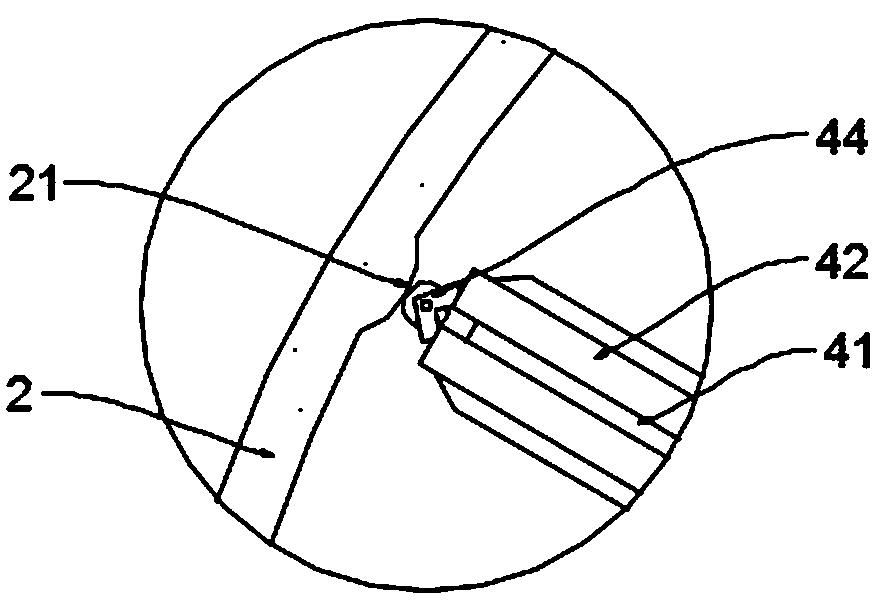

[0024] see Figure 1~4 , in an embodiment of the present invention, a feed refining device for pig farming includes a base 1 and a crushing barrel 2, the crushing barrel 2 is installed on a bracket 12 fixed on the base 1, and the shell wall of the crushing barrel 2 A first through hole 22 is opened, and a rotating shaft 3 is arranged inside the crushing barrel 2, and the rotating shaft 3 is driven by a crushing motor (not shown in the figure) installed on the outer wall of the crushing barrel 2, and the periphery of the shaft body of the rotating shaft 3 is installed When the cutter assembly is working, the rotating shaft 3 drives the cutter assembly to rotate, thereby crushing the feed in the crushing bucket 2 , and the crushed feed falls through the first through hole 22 .

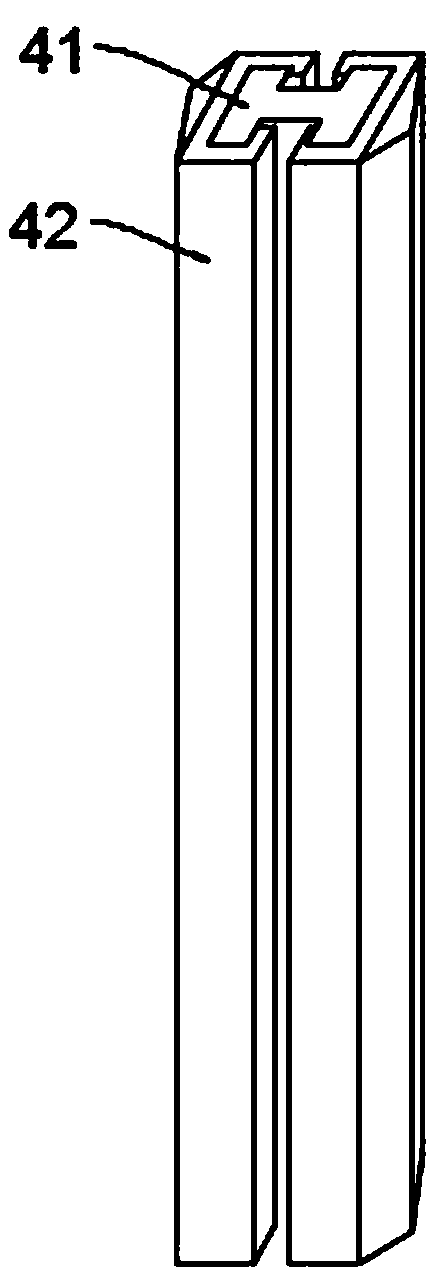

[0025] The cutter assembly includes a knife rest 41 and a blade 42, wherein one end of the knife rest 41 is fixed on the rotating shaft 3, the blade 42 is slidably connected on the knife rest 41 and can ...

Embodiment 2

[0033] The embodiment of the present invention is mainly to describe the drive mechanism in detail on the basis of embodiment 1, specifically:

[0034] The driving mechanism includes a square frame 61 and an incomplete gear 62, wherein the square frame 61 is slidably connected to the vertical plate 11 and can move up and down, and the inner rack 611 arranged symmetrically is integrally formed on the inner side of the square frame 61. An external rack 612 is integrally formed on the outer surface, and the missing gear 62 is rotatably connected and fixed on the mounting bracket 621 of the vertical plate 11. A rotating motor (not shown) driving the missing gear 62 is installed on the mounting frame 621, and the missing gear 62 is located in the square frame 61 and cooperates with the inner racks 611 on both sides; the outer wall of the crushing barrel 2 is integrally formed with ring teeth 63 meshing with the outer racks 612. During operation, the broken gears 62 alternately mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com