Rotary cage type hemisphere screening device for oblique rolling sphere production

A screening device and rotary cage technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of high cost and low efficiency of manual sorting hemisphere, and achieve low manufacturing cost, saving labor cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

[0040] In the production process of ball parts such as skew rolling mill steel balls, bearing balls, copper balls and steel balls, hemispheres (incomplete spheres, collectively referred to as hemispheres) will be produced at the head and tail of each section of round bar material. The device of the present invention is used to screen the above-mentioned Hemispheres generated during production.

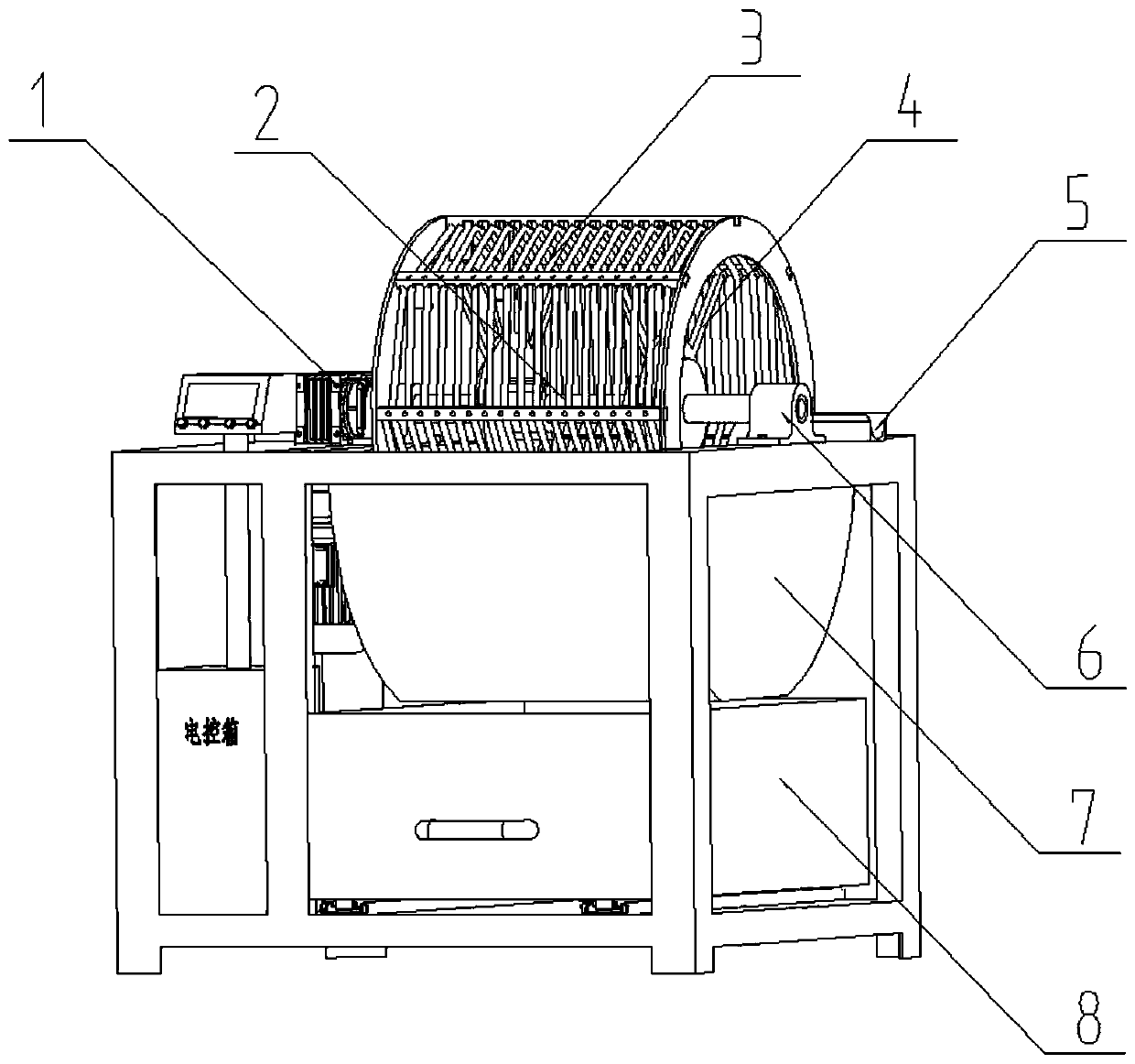

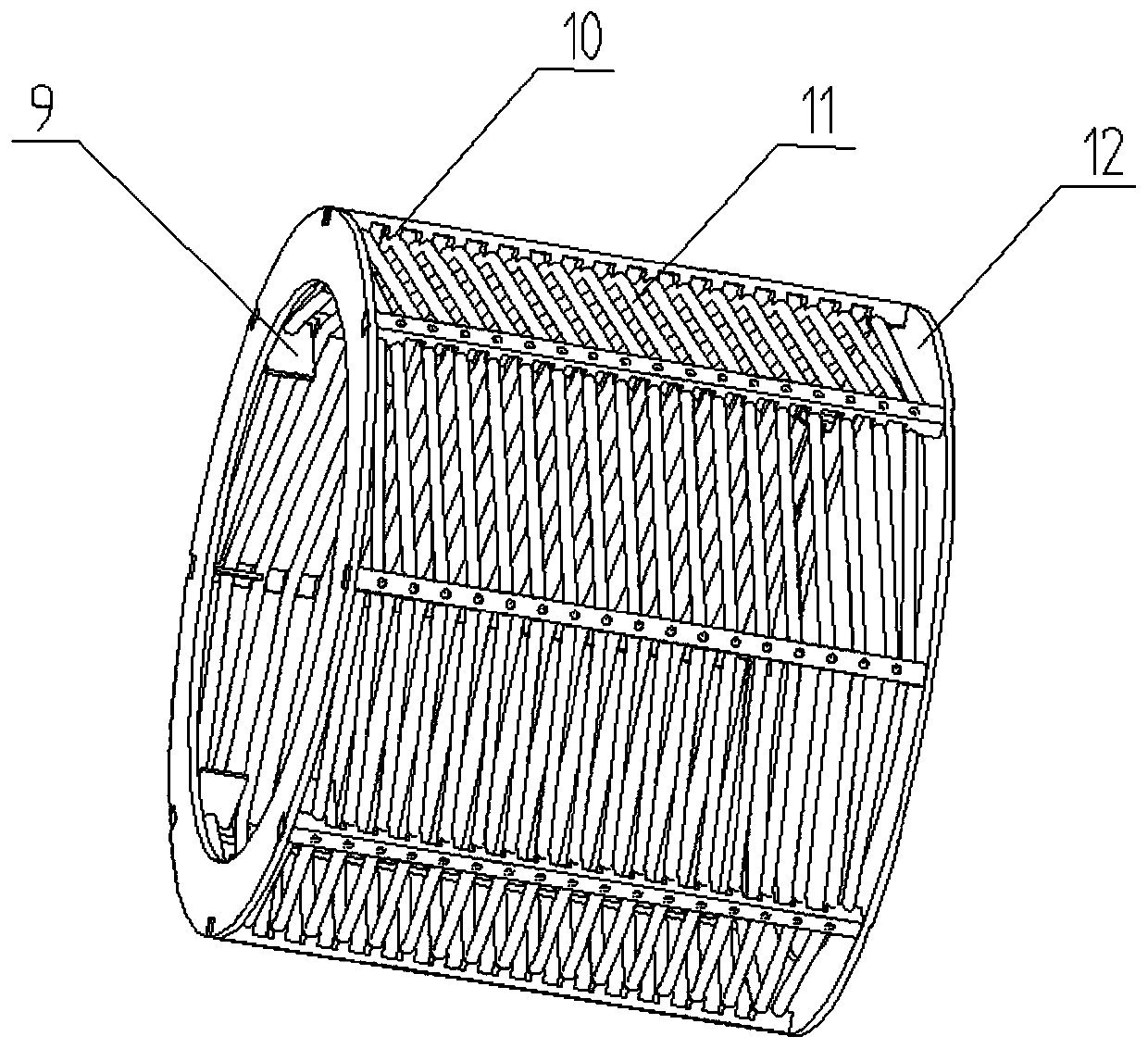

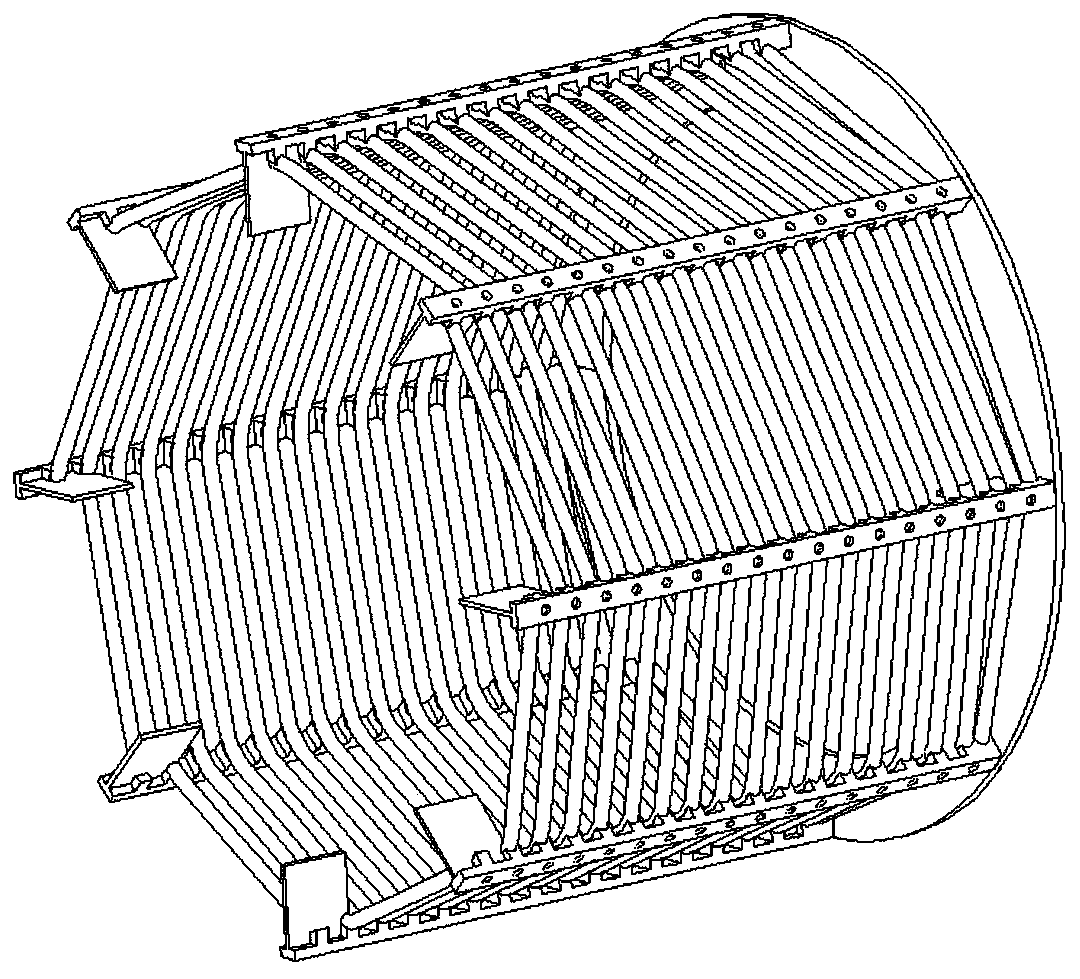

[0041] Such as figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com