Intelligent tool mechanism for installing and polishing gate

A tooling and gate technology, applied in the direction of grinding frame, grinding workpiece support, grinding machine parts, etc., can solve problems such as unfavorable grinding, inconvenient clamping, complex structure, etc., and achieve high positioning accuracy, convenience and intelligence The effect of chemical grinding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

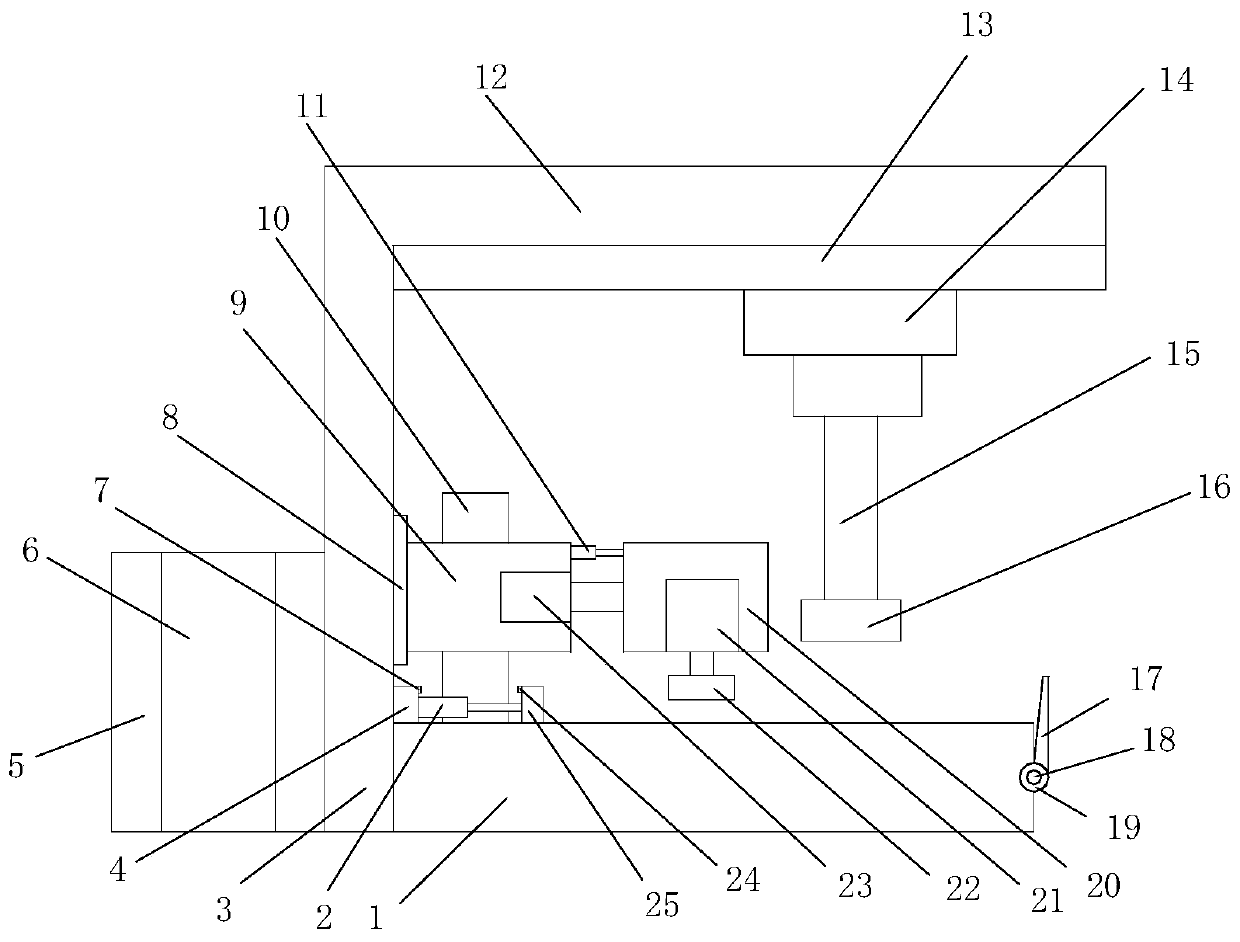

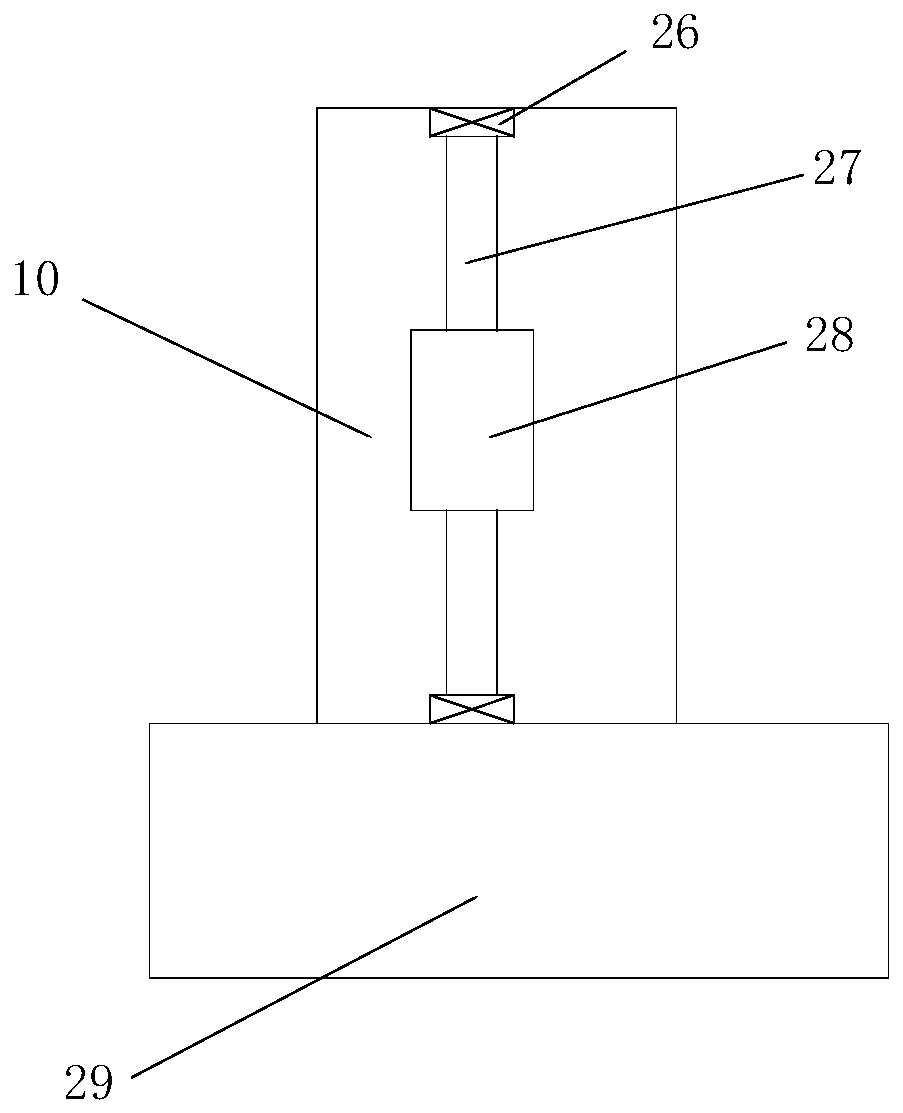

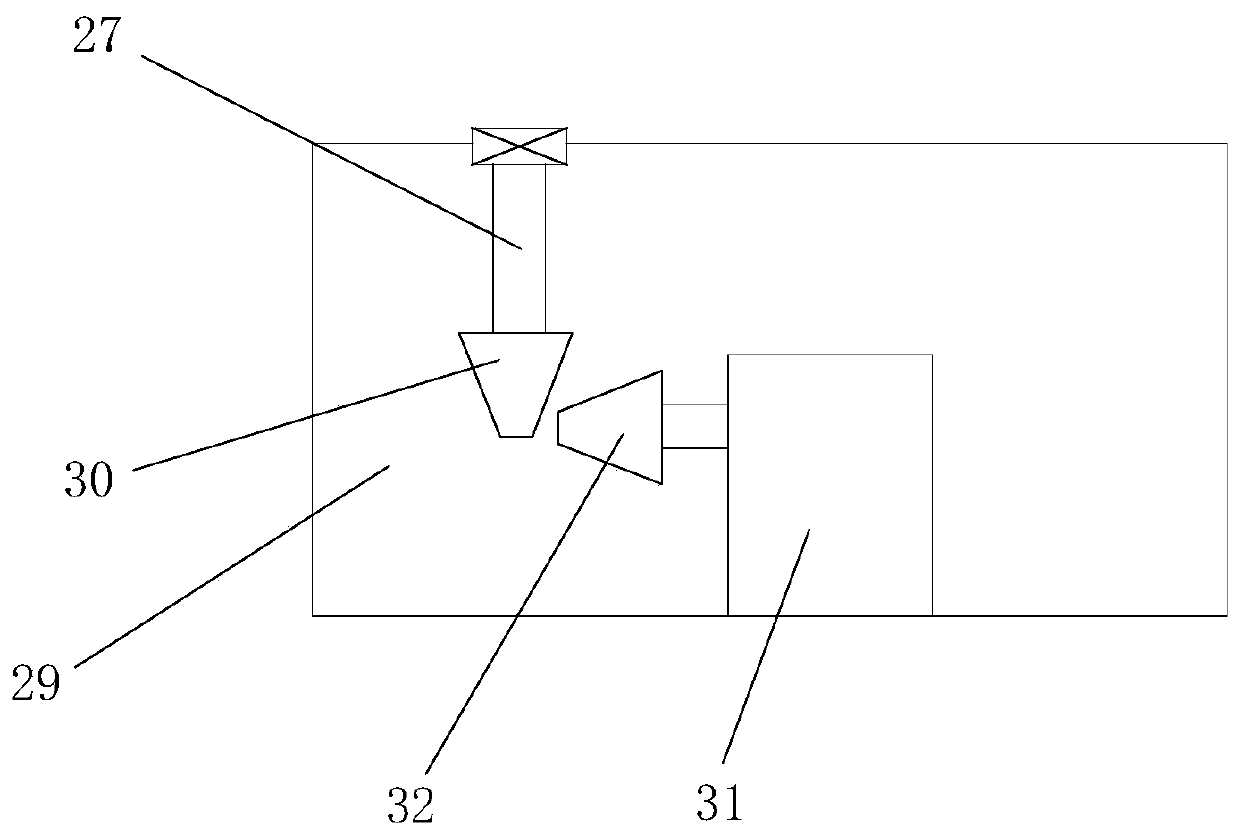

[0027] Embodiment one, with reference to Figure 1~4 , an intelligent tooling mechanism for gate installation and polishing, comprising a base 1, a vertical support 3 is provided at the end of the base 1, a crossbeam 12 is provided at the top of the vertical support 3, and a mobile tooling fixture is provided on the base 1 mechanism, the tooling fixture mechanism includes a tooling head 20, a suction pump 21 is arranged in the tooling head 20, a suction cup 22 is arranged on the lower side of the tooling head 20, and the suction pump 21 communicates with the suction cup 22; the tooling head 20 Fixed on the side of the vertical support 3 by the mobile seat 9, the mobile seat 9 is slidably connected with the vertical support 3, the mobile seat 9 is installed on the base 1 through a lifting mechanism, and the tooling head 20 is connected to the mobile seat 9 by a horizontal telescopic mechanism. connected, the lower side of the beam 12 is provided with a three-axis grinding mecha...

Embodiment 2

[0033] Embodiment 2, this embodiment adds the following technical features on the basis of Embodiment 1: the bottom of the vertical support 3 is provided with a positioning mechanism corresponding to the base 1, the positioning mechanism includes a fixed positioning seat 4 and a mobile positioning seat, and the fixed positioning seat 4 is fixed on the bottom of the vertical support 3, the mobile positioning seat is connected with the fixed positioning seat 4 through the elastic telescopic sleeve 2, and the positioning mechanism is provided with a laser displacement sensor, the laser displacement sensor includes a laser transmitter 24 and a laser receiver 7, and the laser The transmitter 24 is provided with the top of the mobile positioning seat, and the laser receiver 7 is correspondingly arranged on the top of the fixed positioning seat 4 .

Embodiment 3

[0034]Embodiment 3, this embodiment adds the following technical features on the basis of Embodiment 1: the end of the base 1 corresponding to the other side of the vertical support 3 is provided with a limit mechanism, and the limit mechanism includes a limit baffle 17 , the limit baffle 17 is a wedge-shaped baffle, and the bottom end of the limit baffle 17 is hinged on the outer end side wall of the base 1 through a hinge shaft 18, and a torsion spring 19 is arranged on the hinge shaft 18.

[0035] The working principle of the present invention: the present invention provides an intelligent tooling mechanism for gate installation and polishing. The present invention adopts an adsorption-type tooling mechanism, which can lift and move laterally, and is convenient for clamping the tooling before the gate is polished. Further, the present invention uses a three-axis grinding mechanism. Grinding is convenient for intelligent grinding operations; the present invention is further p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com