Limiting tool for bonding bracket and carbon strip of intelligent carbon sliding plate and limiting method thereof

A technology of carbon slides and carbon strips, which is applied in the direction of workpiece clamping devices, connecting components, manufacturing tools, etc., can solve the problems of uneven clamping force of each stud, inconsistent quality of carbon slides, inconvenient clamping and disassembly, etc. Achieve the effect of uniform connection resistance, uniform clamping force and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

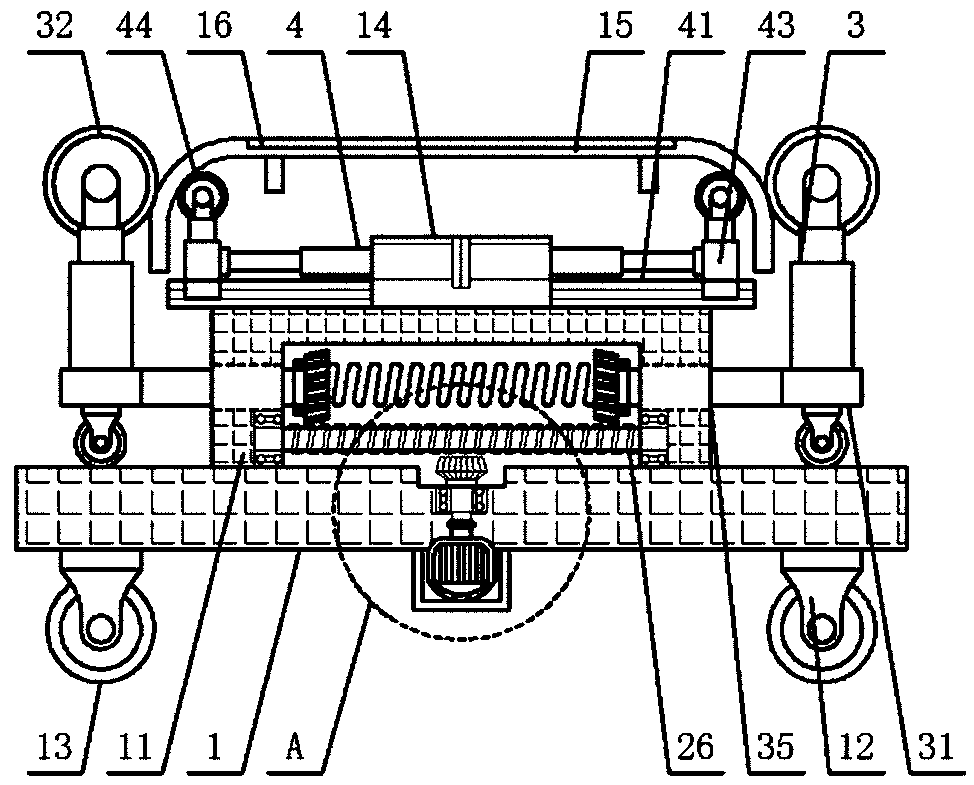

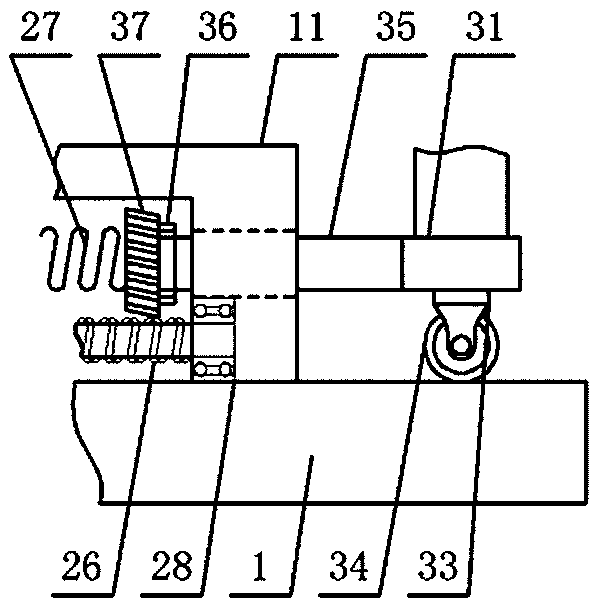

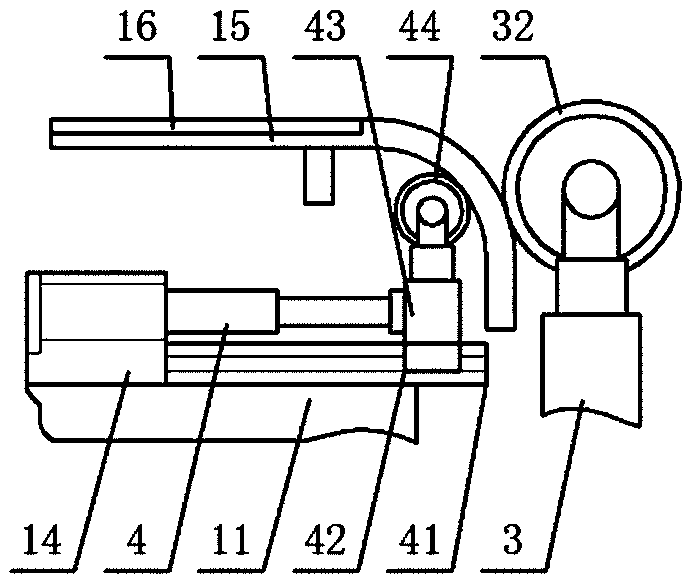

[0034] Example 1: see Figure 1-4 , The limit tool for bonding the smart carbon slide bracket and the carbon strip, includes a bottom plate 1, a carbon slide plate 15. The bottom plate 1 is a horizontally placed rectangular plate, and the top surface of the bottom plate 1 is horizontally provided with an inverted U-shaped seat 11. Both ends of the U-shaped seat 1 are provided with sliding holes passing through, and sliding rods 35 are installed in the sliding holes, the top surface of the bottom plate 1 is recessed with a through hole, and the bottom surface of the bottom plate 1 is centered. A motor seat 21 is provided directly below the through hole, and a motor 2 is installed in the motor seat 21, and the top end of the motor shaft of the motor 2 is movably connected to the inner end of the sliding rod 35 through a transmission mechanism;

[0035] The carbon slide plate 1 is horizontally and transversely inverted and is located directly above the top surface of the U-shaped se...

Embodiment 2

[0041] Example 2: see Figure 5 In this embodiment, the present invention also proposes a limit method for a limit tool for bonding a smart carbon skateboard bracket and a carbon strip, including the following steps:

[0042] Step 1: The tail end of the first telescopic cylinder 43 is electrically connected to an external power source through a first wire, the tail end of the second telescopic cylinder 3 is electrically connected to an external power source through a second wire, and the tail end of the electric cylinder 4 is electrically connected to an electric wire. It is electrically connected to the external power source, and the tail end of the motor 2 is connected to the external power source through the motor wire;

[0043] Step 2: Adjust the distance between the two first limit wheels 44 through the sliding assembly according to the distance between the inner bends at both ends of the carbon sliding plate 15; control the expansion and contraction of the electric rod of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com