A kind of rapid prototyping equipment for the production of plastic masterbatch with high stability

A technology of plastic masterbatch and molding equipment, applied in the direction of coating, etc., can solve the problems of unstable additive and filler structure, falling off, reducing the quality of plastic masterbatch products, etc., and achieve compact structure, safe and convenient use, and prevent falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

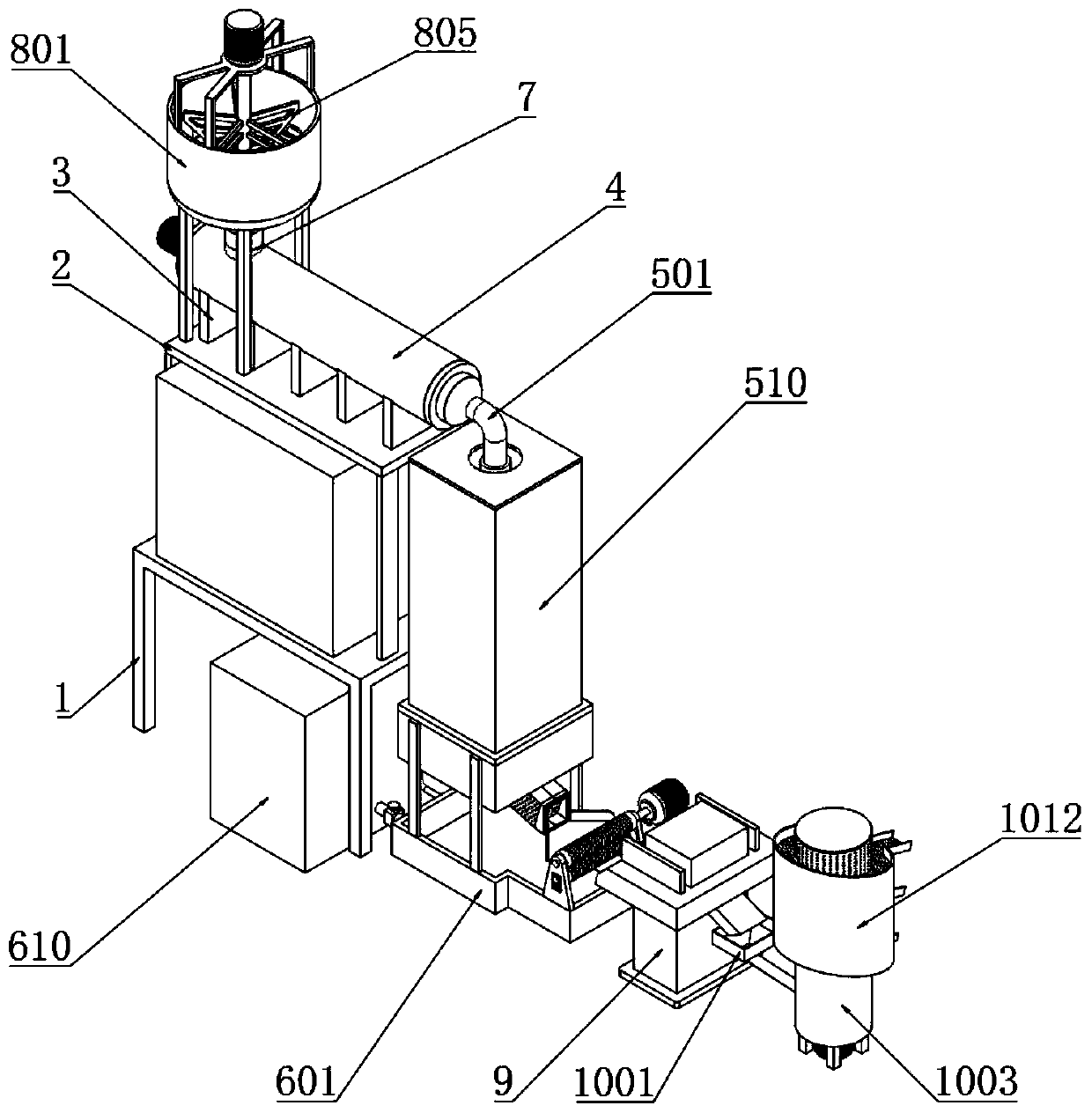

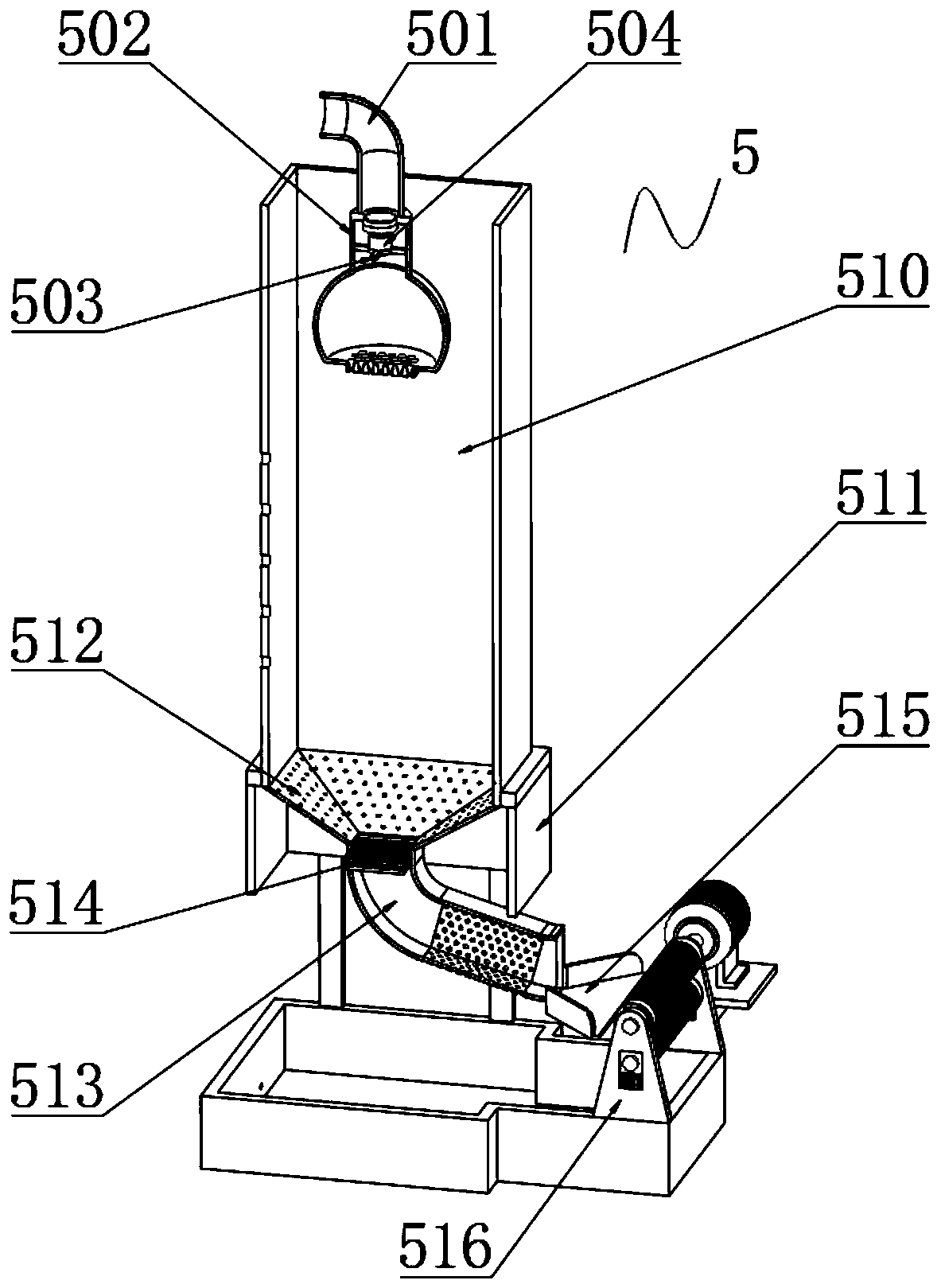

[0051] Example: such as Figure 1-9 As shown, the present invention provides a kind of technical scheme, a kind of rapid prototyping equipment for the production of plastic masterbatch with high stability, comprising:

[0052] The molding mechanism 5 is used to process the plastic mixture in the molten state into a solid plastic strip;

[0053] The cooling circulation mechanism 6 is used for spraying cooling water and recycling the used cooling water at the same time;

[0054] The feeding mechanism 8 is used to mix the raw materials and intercept the raw materials with larger particles;

[0055] The screening mechanism 10 is used to screen and classify the granulated plastic master batches, so that plastic master batches with different particle sizes can be stored separately;

[0056] The material storage mechanism 11 is used for storing the processing raw materials nearby.

[0057] It includes a support table 1, the top of the support table 1 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com