Triple-hulled vessel

A technology of trimaran and hull, which is applied in the direction of hull, ship construction, non-magnetic metal hull, etc., can solve the problems such as the adverse effects of ship navigation stability and rapidity, the increase of ship manufacturing cost, the space occupied by protective structure, etc. The effect of lightness, increased sailing speed, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

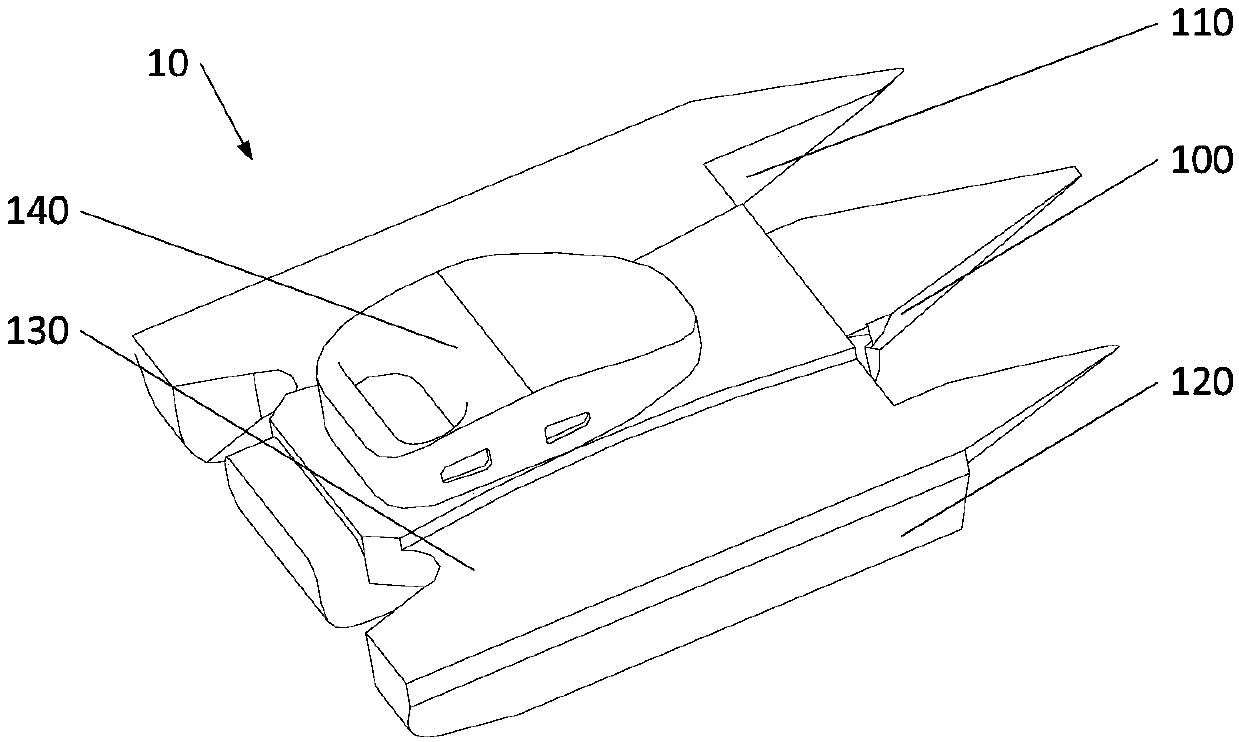

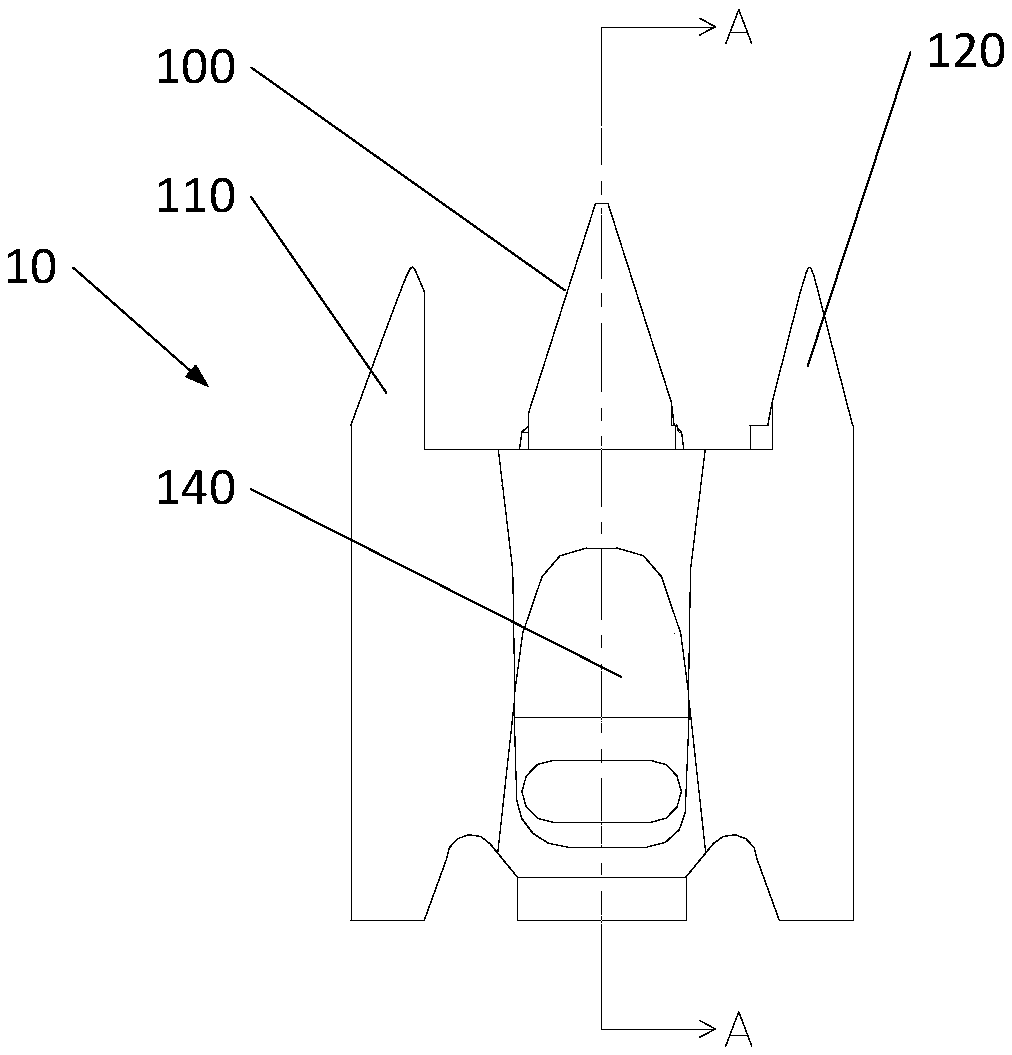

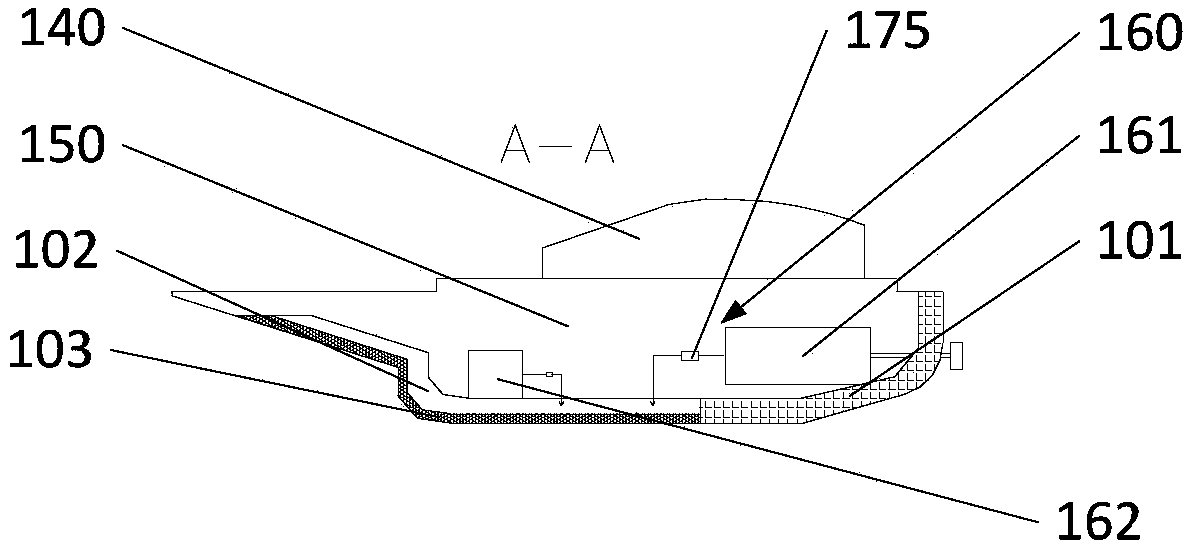

[0022] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a trimaran 10, including a main hull 100, a first auxiliary hull 110 and a second auxiliary hull 120, and the first auxiliary hull 110 and the second auxiliary hull 120 are arranged on two sides of the main hull 100. On the side, the main hull 100 is provided with an engine room 150 , and a power system 160 is arranged in the engine room 150 .

[0023] Wherein, the first auxiliary hull 110 and the second auxiliary hull 120 can be symmetrically distributed on both sides of the main hull 100 to improve the stability of the trimaran. The trimaran 10 can also include a deck 130 and a cockpit 140, the first subhull 110, the main hull 100 and the second subhull 120 can be arranged below the deck 130 to support the deck 130 together, and the cockpit 140 can be positioned above the deck 130 . In this way, the main hull and the two auxiliary hulls can jointly support a wider deck, further ...

Embodiment 2

[0126] The embodiment of the present invention also provides another trimaran, comprising a main hull, a first auxiliary hull and a second auxiliary hull, the main hull is provided with an engine room, the engine room is provided with a power system, and the power of the power system The source is a gas turbine engine;

[0127] The bottom of the main hull is also provided with a pressure chamber, the bilge of the pressure chamber has several injection holes, the pressure chamber communicates with the exhaust pipe of the gas turbine engine, and the exhaust pipe is connected to the pressure chamber. A one-way valve is arranged between the compartments.

[0128] Further, implementations related to the impact-resistant structure of the trimaran and / or the structure of the power system in Embodiment 1 can also be applied to the trimaran of the embodiment of the present invention, and have the same beneficial effects. To avoid repetition, the This will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com